Scattered leaf stacked tobacco-roasting house and its leaf roasting method

A technology of flue-cured tobacco room and tobacco leaves, which is applied in the field of flue-cured tobacco room, which can solve the problems of large vertical temperature difference, low utilization rate, high price of flue-cured tobacco oven, and achieve the effect of preventing roasting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

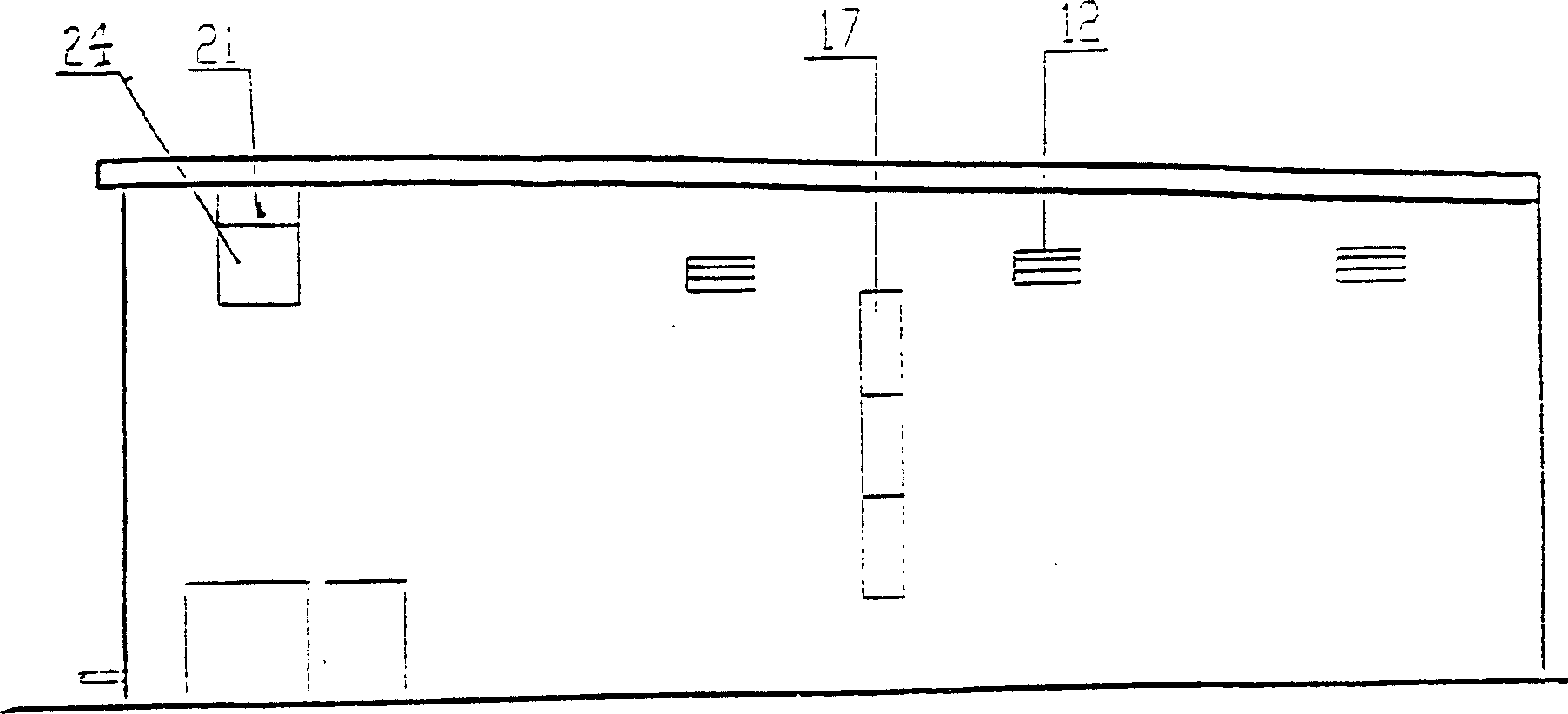

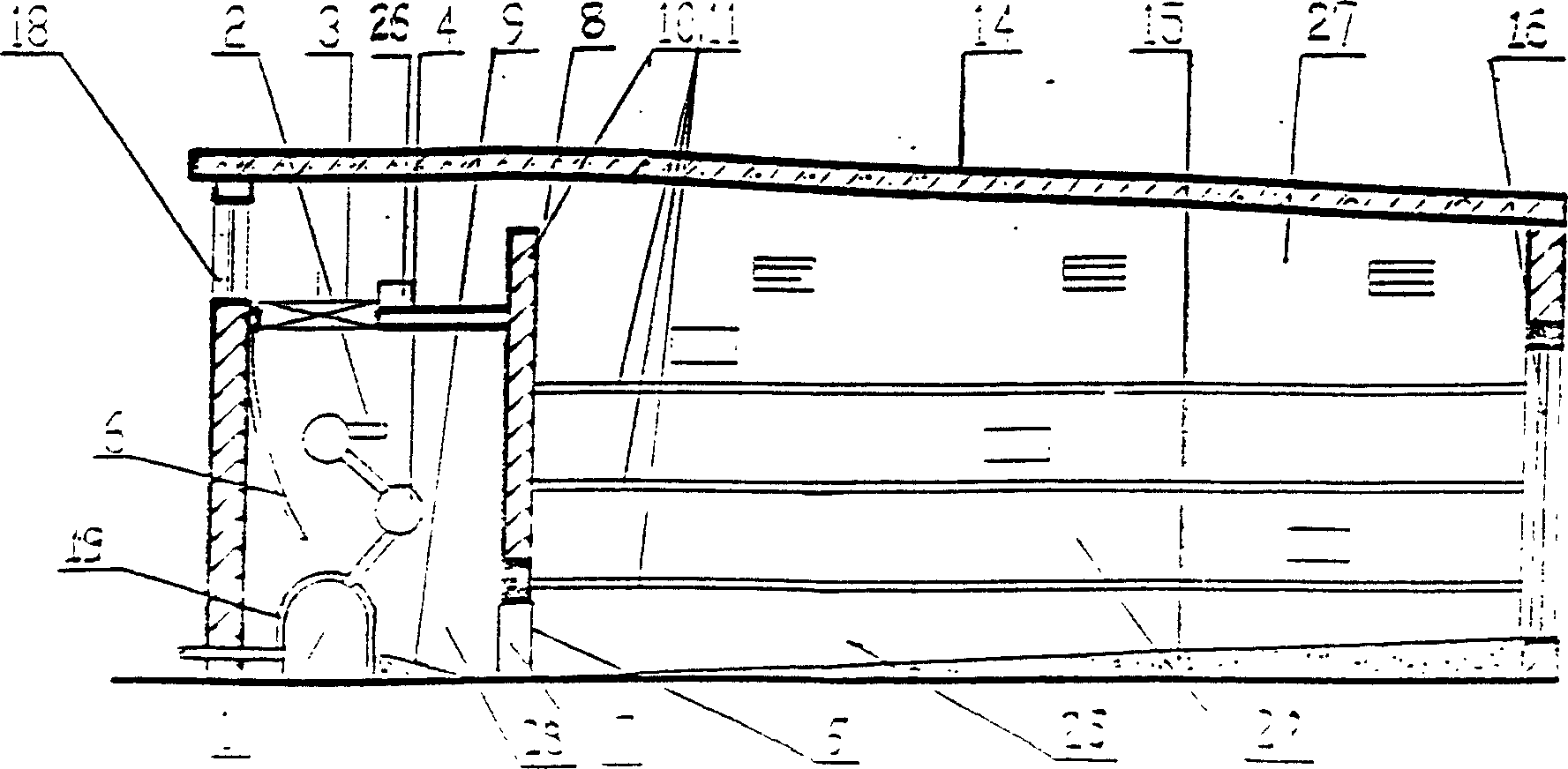

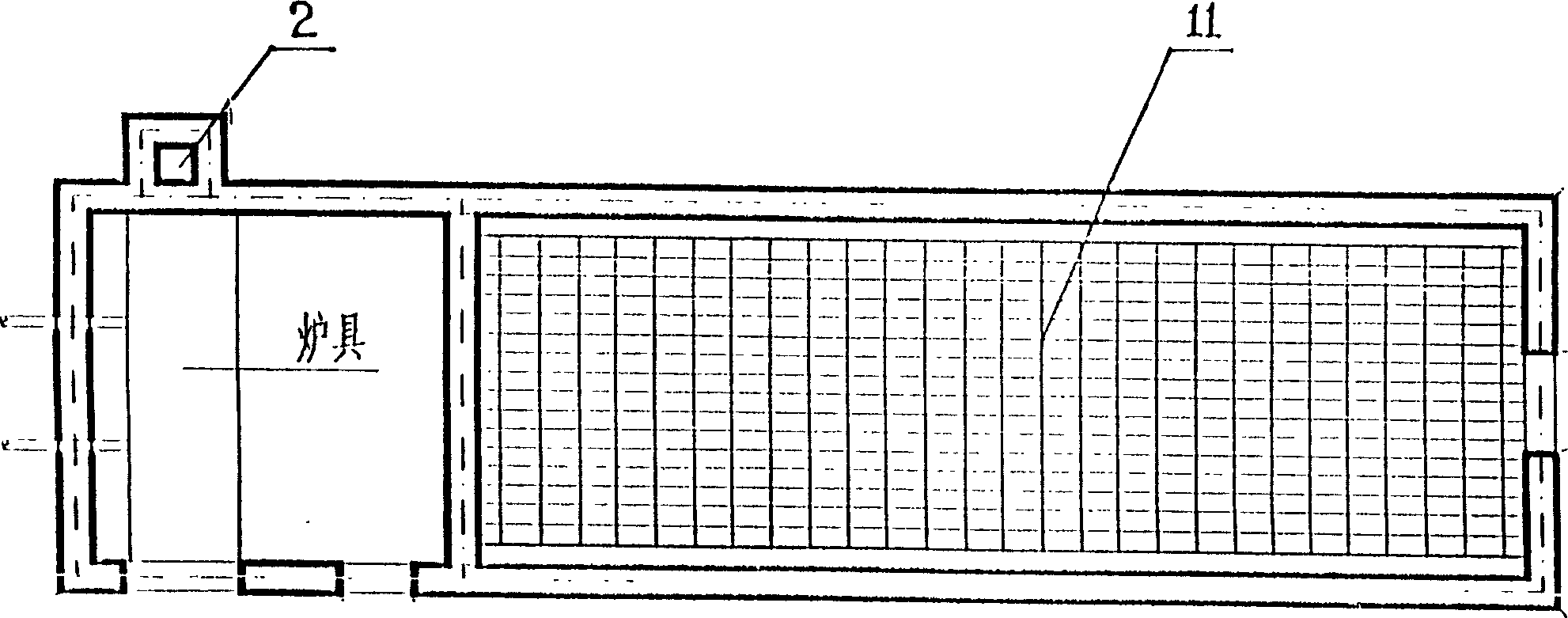

[0039] Embodiment one, see Figure 1-3 , the figure shows a loose-leaf stacked flue-cured tobacco room, which includes: a room body, a heating system and a hot air circulation system, and is characterized in that the room body includes two chambers arranged side by side: a heating chamber 28 and a smoke chamber 29; the heating system is set in the heating chamber 28, and the smoke stack grid 11 is arranged in the smoke chamber 29; the hot air circulation that circulates the hot air between the heating chamber 28 and the smoke chamber 29 The system is located in the heating chamber 28 and the smoke chamber 29 and communicates with the heating chamber 28 and the smoke chamber 29;

[0040] The heat supply system of described heating chamber 28 comprises; Heater 1, chimney 2, blower fan 3,, air inlet 21, hot blast outlet 7, there is the stove of adorning molded coal or scattered coal in described heater 1, heater 1 is connected with the chimney 2 outside the wall opposite the fur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com