Three-section six-step tobacco baking method

A curing method and tobacco leaf technology are applied in the directions of tobacco, tobacco preparation, application, etc., and can solve the problems of increasing the curing cost, affecting the curing quality of tobacco leaves, and low density of cigarettes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in detail below in conjunction with specific embodiments.

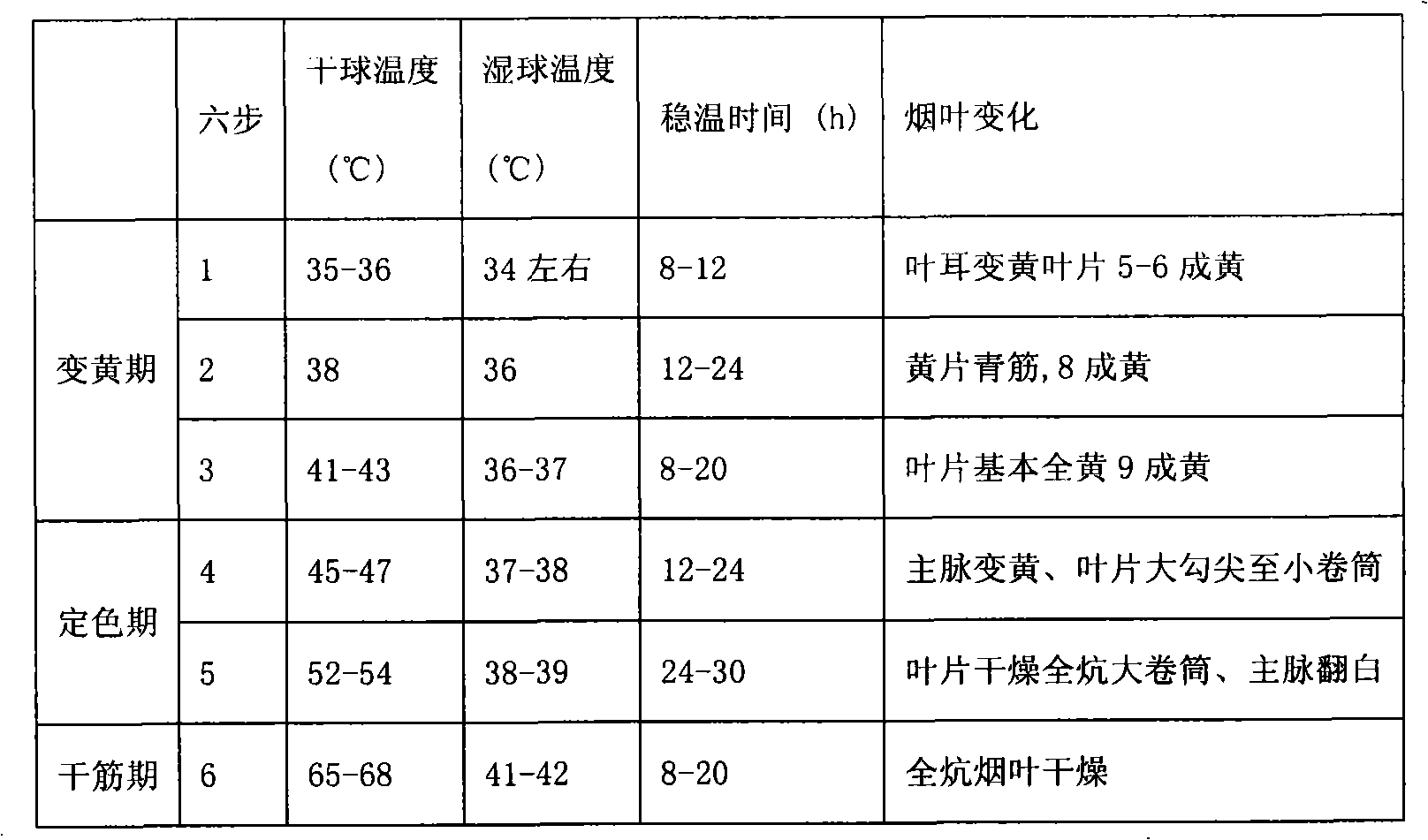

[0012] 2.3.1 Three-stage six-step baking process

[0013]

[0014] Note: The airflow descending barn, the change of tobacco leaves is mainly on the top layer

[0015] 2.3.2 Three-stage six-step baking operation technology

[0016] 2.3.2.1 Yellowing period

[0017] 2.3.2.1.1 The first step is to balance the temperature and humidity

[0018] After the fire started, the dry bulb temperature of the top table was raised to 35-36°C and the wet bulb temperature was adjusted to about 34°C at an average temperature increase rate of 1°C per hour, until the top table tobacco leaf ears turned yellow and the degree of yellowing of the tobacco leaves reached 5°C. -6 into yellow.

[0019] 2.3.2.1.2 The second step is to solve the yellowing of tobacco leaves

[0020] With an average temperature rise rate of 0.5°C per hour, the dry bulb temperature of the top table was raised from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com