Precision five-phase quintuple-correspondence roasting bulk-curing process for tobacco

An intensive roasting and intensive roasting room technology is applied in the field of precise roasting and roasting of tobacco leaves corresponding to five sections and five. Precise and quantitative operation, the effect of not easy to hang dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

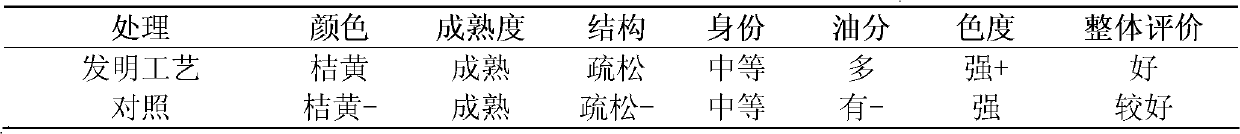

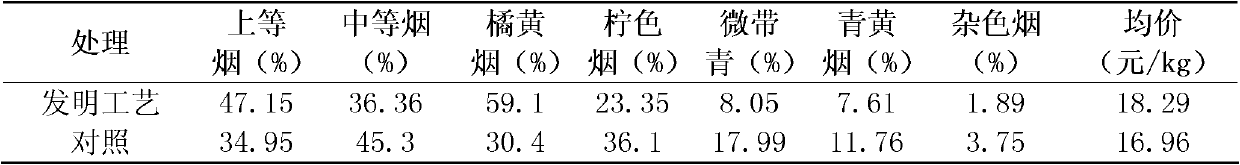

Examples

specific Embodiment approach

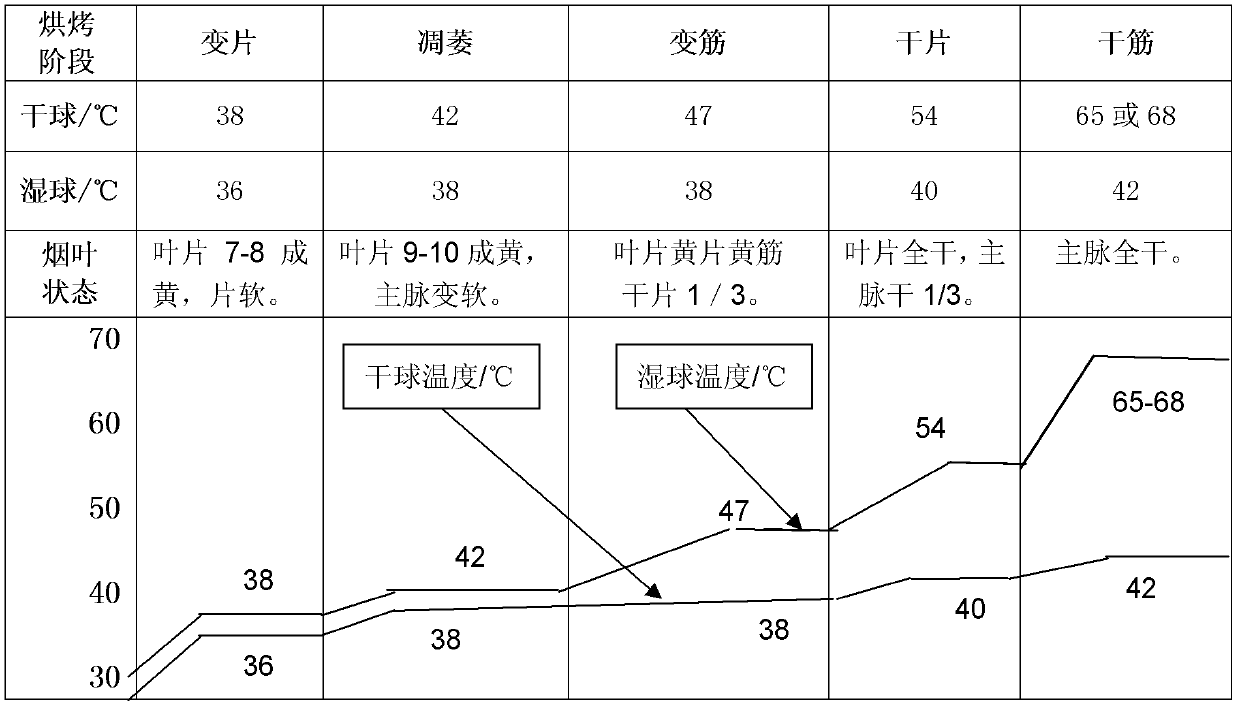

[0019] The specific embodiment of technique of the present invention is as follows:

[0020] 1 Tobacco leaf preparation before roasting: select flue-cured tobacco leaves with uniform maturity, and use 1.50m tobacco rods to weave tobacco. There are two ways of manual weaving and mechanical weaving. Each rod weaves 100-120 pieces of tobacco, which is equivalent to each rod The weight of fresh smoke is 9-11kg, and the rod distance is 11-12cm. Cigarette clips are determined by the specifications of the cigarette clips, and each room is guaranteed to contain about 4000kg of fresh cigarettes. The location of the thermometer sensor: the temperature sensing head is hung 200cm away from the partition wall, and the side wall is 100cm away. The air flow is about 10cm away from the ceiling of the smoking room in the dense curing room and enters the smoke layer from the bottom of the petiole. Into the smoke layer about 10cm.

[0021] 2 Process operation steps:

[0022] [1] Tobacco leaf ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com