Biomass-based direct-reduction ironmaking device and method

A biomass and direct technology, applied in the direction of reducing gas emissions, can solve the problems of no fundamental improvement in environmental pollution and carbon emission reduction, slow progress in research and application, and no advantages in comprehensive benefits, and achieve clean production and get rid of fossil energy. Dependent, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

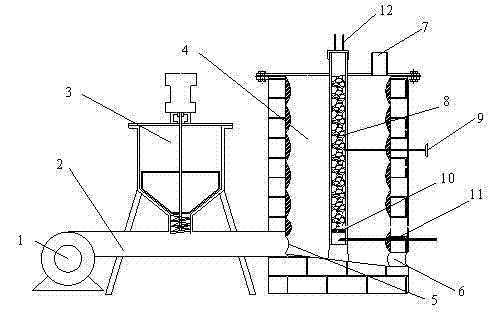

[0040] Such as figure 1 Shown, the present invention provides a kind of direct reduction ironmaking plant based on biomass, and it comprises fan 1, air powder premixing pipe 2, biomass feeder 3 and combustion chamber 4, and described biomass feeder 3 It is connected with the air powder premixing pipe 2, one end of the air powder premixing pipe 2 is connected with the fan 1, and the other end is the biomass powder and the combustion air inlet 5, and the biomass powder and the combustion air inlet 5 are along the combustion chamber 4 The lower part extends into the interior of the combustion chamber 4 in a tangential direction. After the biomass delivered by the biomass feeder 3 and the combustion-supporting air provided by the fan 1 are fully mixed in the air-powder pre-mixing pipe 2, the powder and the combustion-supporting air inlet 5 Enter combustion chamber 4 and burn.

[0041] The combustion chamber 4 is cylindrical, the bottom of the combustion chamber 4 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com