Biomass combustion boiler

A biomass and boiler technology, applied in the boiler field, can solve the problems of incomplete combustion of biomass particles, low combustion efficiency, and high combustion heat, and achieve the effects of simple structure, sufficient fuel combustion, and improved combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

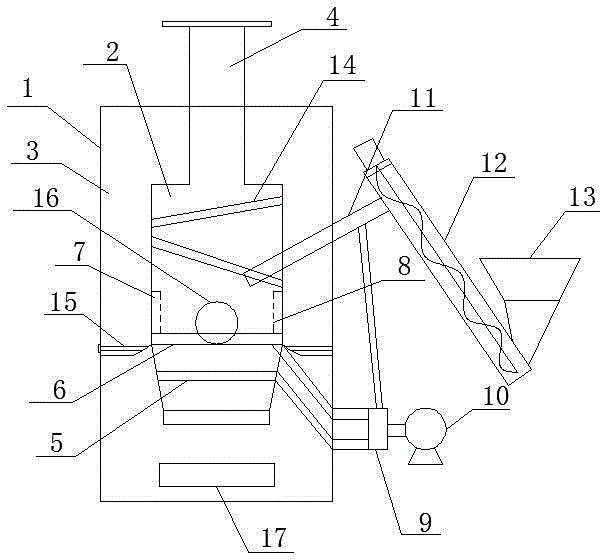

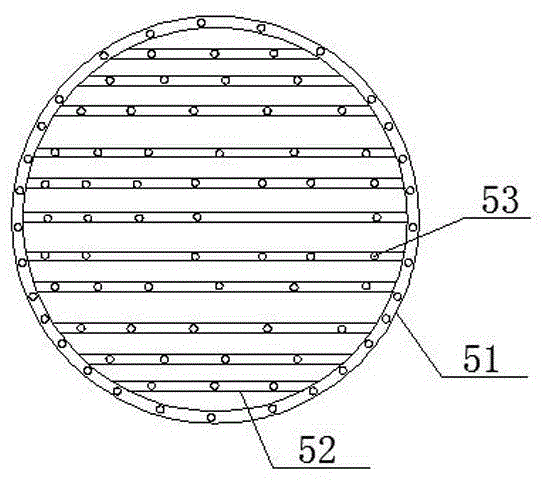

[0014] like figure 1 and figure 2 A biomass combustion boiler shown includes an outer casing 1 and an inner combustion chamber 2, a water storage chamber 3 is provided between the casing 1 and the combustion chamber 2, and a flue 4 is arranged on the top of the casing 1. The lower part of the chamber 2 is provided with a fire grate 5, which includes a first circular support tube 51 attached to the inner wall of the combustion chamber 2 and a plurality of ribbed tubes 52 arranged side by side on the first circular support tube 51. A circular support pipe 51 and ribbed pipe 52 are provided with a plurality of upper exhaust air holes 53 for upward air discharge; a second circular support pipe 6 that fits with the inner wall of the combustion chamber 2 is provided above the grate 5, and the second round The shape support pipe 6 is provided with a plurality of vertical blowpipes 7 communicating with it, and the second circular support pipe 6 and the vertical blowpipe 7 have a plu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com