Ultra-low nitrogen premixed gas burner and combustion method thereof

A gas burner, ultra-low nitrogen technology, applied in the direction of combustion methods, gas fuel burners, burners, etc., can solve the problems of limited use of burners, reduced combustion efficiency, etc., and achieve simple installation, stable combustion, and high combustion flame short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

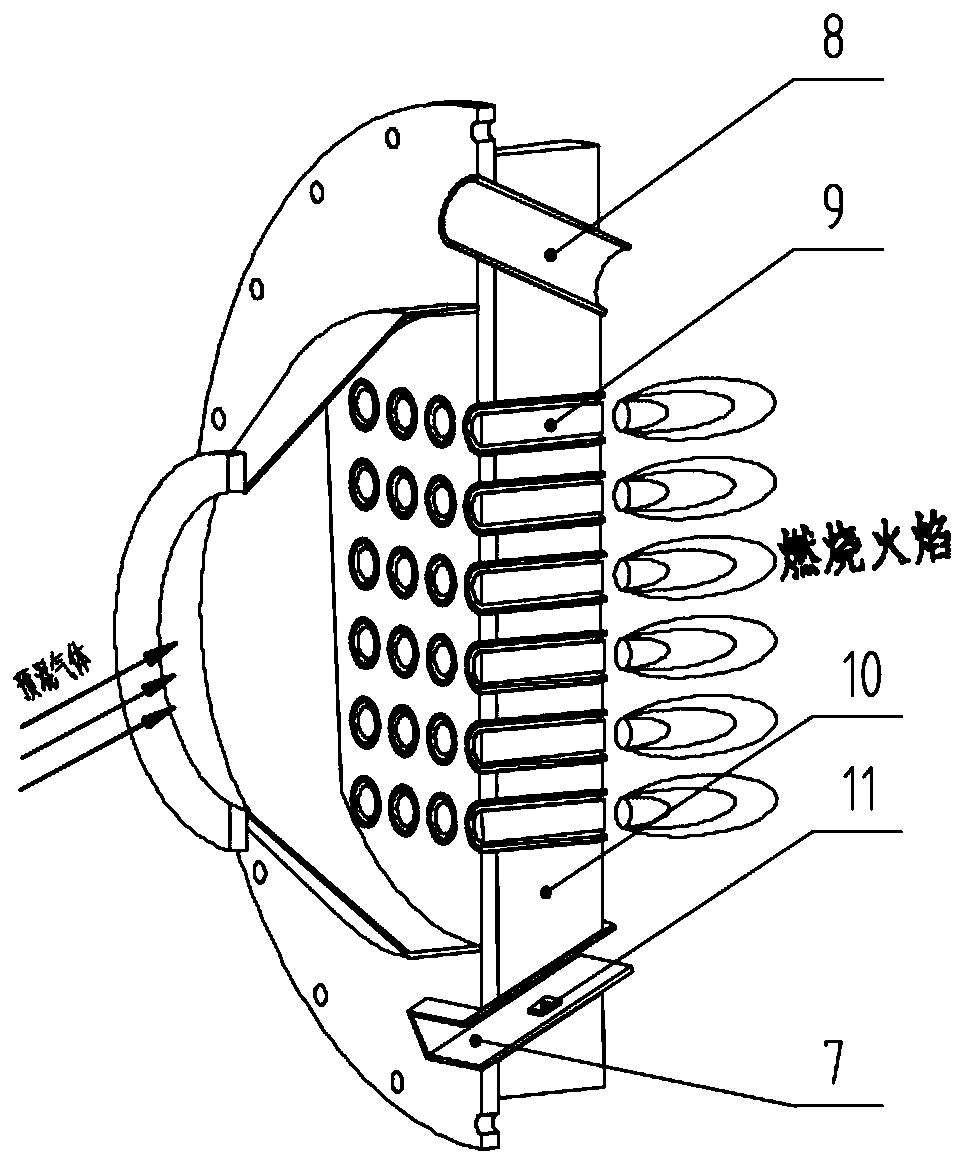

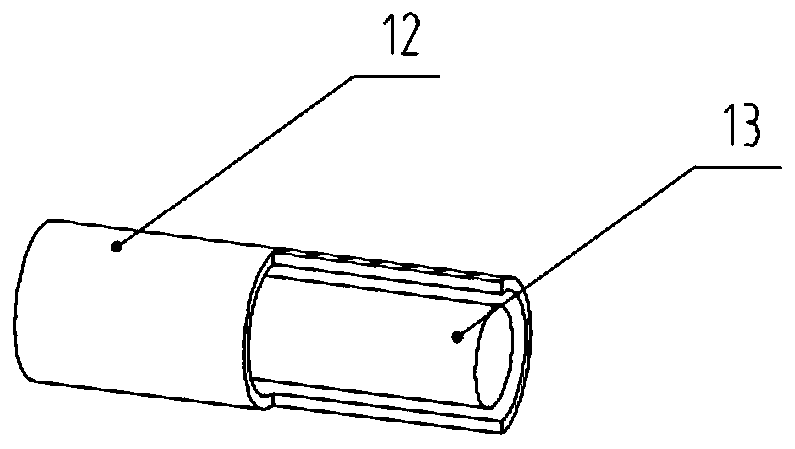

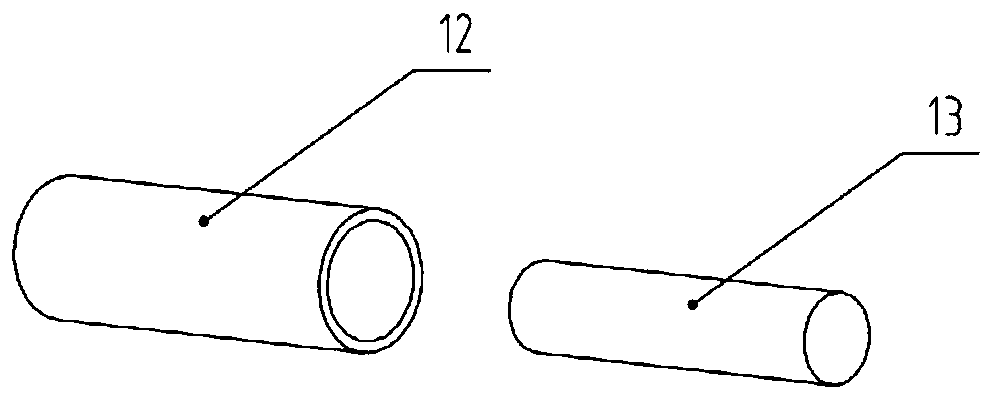

[0034] Such as Figure 1-7 As shown, this embodiment is an ultra-low nitrogen premixed gas burner, including several nozzles 9 arranged at the end of the burner, and the burner is connected to the furnace through the nozzles 9 . The premixed gas in the burner is evenly distributed through the nozzle 9 and enters the furnace, and the premixed gas is ignited at the outlet end of the nozzle 9 and then defires and burns in the furnace. The nozzle 9 includes a hollow shell 12 and a solid blunt body 13 , the shell 12 is sheathed outside the blunt body 13 , and a channel for the premixed gas to flow is formed between the shell 12 and the blunt body 13 . The casing 12 is cylindrical with two ends open, the blunt body 13 is cylindrical, and the length of the casing 12 is basically the same as that of the blunt body 13 . In this embodiment, a large number of nozzles 9 are arranged at the end of the burner, so that the premixed gas circulates in the channels of the nozzles 9 and defires...

Embodiment 2

[0039] This embodiment also provides a combustion method of an ultra-low nitrogen premixed gas burner, comprising the following steps:

[0040] S1, mix air and gas according to the set ratio to form premixed gas, and pass the premixed gas into the distribution chamber;

[0041] S2, the premixed gas in the distribution chamber is evenly distributed through several nozzles and then enters the furnace:

[0042] S3, igniting the premixed gas at the outlet of the nozzle, so that the premixed gas is defired and burned in the furnace.

[0043] Wherein, in step S1, several nozzles with a certain length are provided on the outlet end surface of the distribution chamber. In step S2, the premixed gas in the distribution chamber enters the furnace along the channel in the nozzle. In step S3, the premixed gas is defired and burned, the combustion is violent, the combustion flame is short, the combustion is stable, the heat transfer efficiency is high, and the NOx content of the generated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com