Dual-peak exhaust camshaft

A technology of exhaust cam and camshaft, which is applied in the direction of exhaust gas recirculation, adding non-fuel substances to fuel, valve details, etc., can solve the problems of power reduction, accelerated intake valve wear, limited NOx emission effect, etc., to reduce NOx Discharge, avoid wear, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

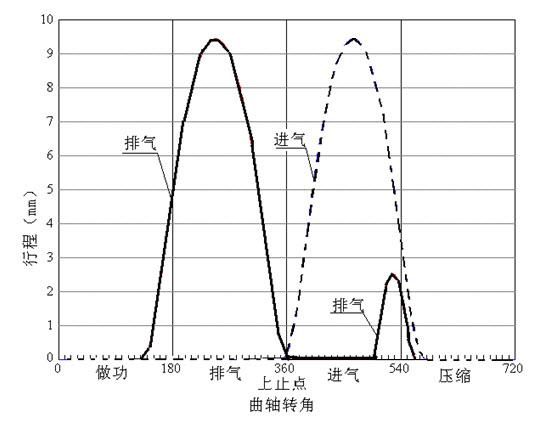

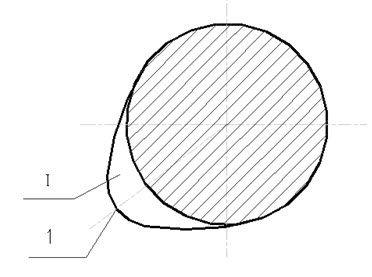

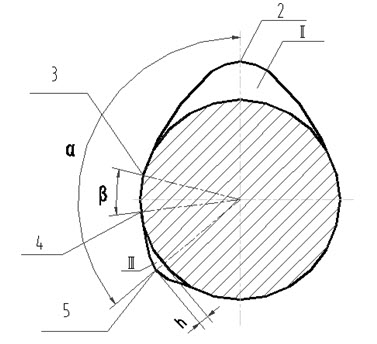

[0011] The technical principles of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. like figure 1 and figure 2 Shown: double-peak exhaust camshaft, including intake cam and exhaust cam, double-peak exhaust camshaft includes one intake cam I and two exhaust cams. The two exhaust cams include exhaust cam II and EGR cam III. The exhaust cam II and EGR cam III share a base circle, and the transition between the exhaust cam and the EGR cam is smooth to ensure manufacturability. The maximum lift of intake cam I and exhaust cam II is 5.5mm-9.5mm, the maximum lift of EGR cam III is 0.5mm-2.5mm, and the included angle between the centerlines of intake cam I and exhaust cam II is 90°-140° cam rotation angle (cam rotation angle is the unit of included angle), and the included angle α between exhaust cam centerline 2 and EGR cam III centerline 5 is 90°-150° cam rotation angle. The angle β between the end poin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com