Distributed Air and Fuel Humidification Gas Turbine Combined Cycle Approach

A gas turbine and combined cycle technology, which is applied to gas turbine devices, mechanisms for generating mechanical power, and solar energy to generate mechanical power, can solve problems such as energy waste and difficult and efficient utilization, and achieve improved efficiency, reduced utilization costs, and improved power efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

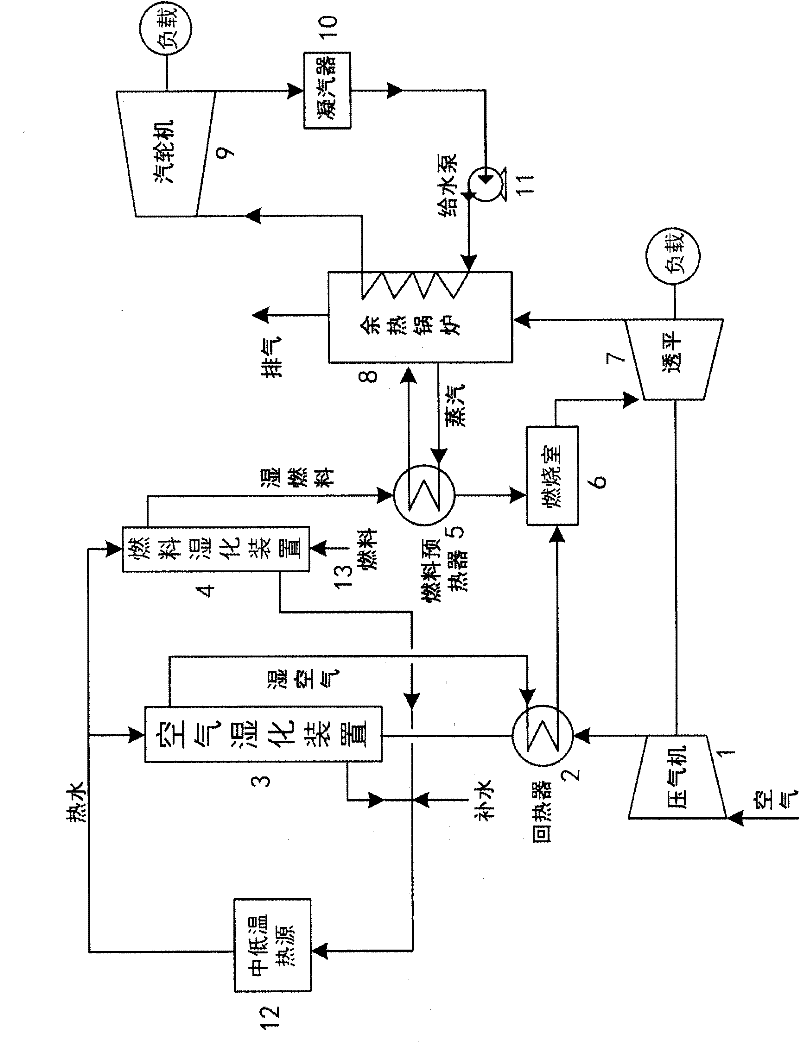

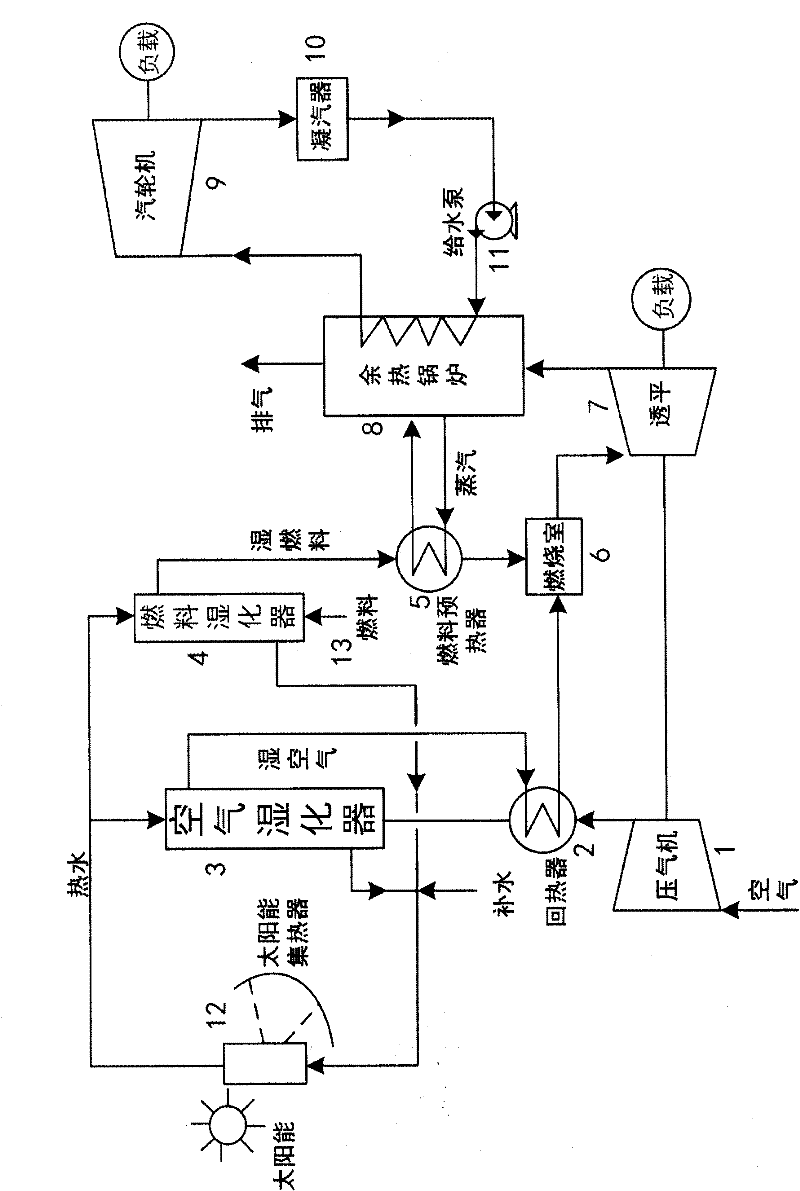

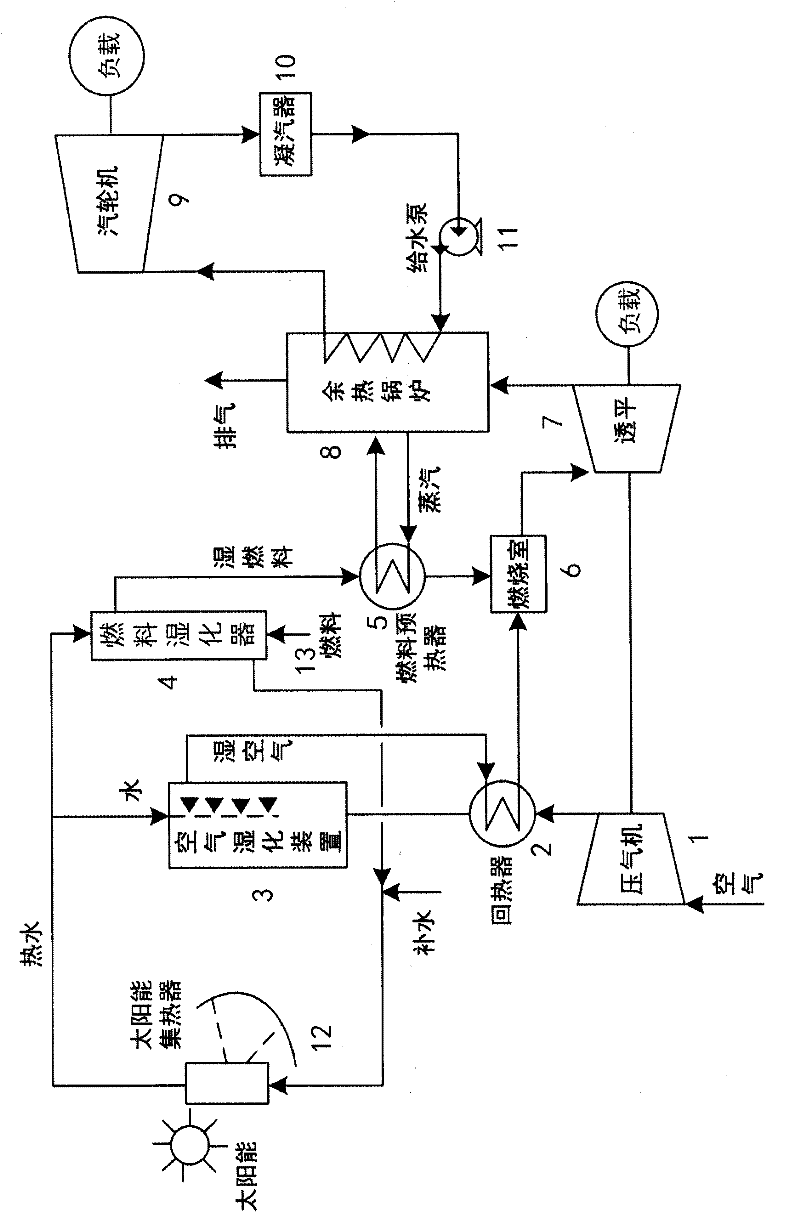

[0035] A thermodynamic cycle scheme that can be used in the distributed air and fuel humidification gas turbine combined cycle method of the present invention is as follows: starting from the starting point of the circulating working medium compression process, 1) compression: the main circulating working medium (air, helium, etc.) flow After being boosted by the compressor, the end of the process is compressed air whose temperature and pressure are higher than the ambient state; 2) High-temperature side process of the regenerator: the main circulating working medium after boosting is in the regenerator (aftercooler) and the low-temperature The side gas exchanges heat in the surface heat exchanger to reduce the temperature; 3) Air humidification: the main circulating working fluid enters the air humidification device, and is drawn out from the humidification device after being humidified; 4) Air preheating: the humid air enters the reheating device 5) Combustion / heating: heat i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com