Connecting structure and grass trimmer head device

A connection structure and the technology of mowing heads, which are applied in the direction of cutters, agricultural machinery and implements, etc., can solve the problems of short service life of the mowing head and easy vibration of the mowing head

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The specific implementation of this embodiment is as follows:

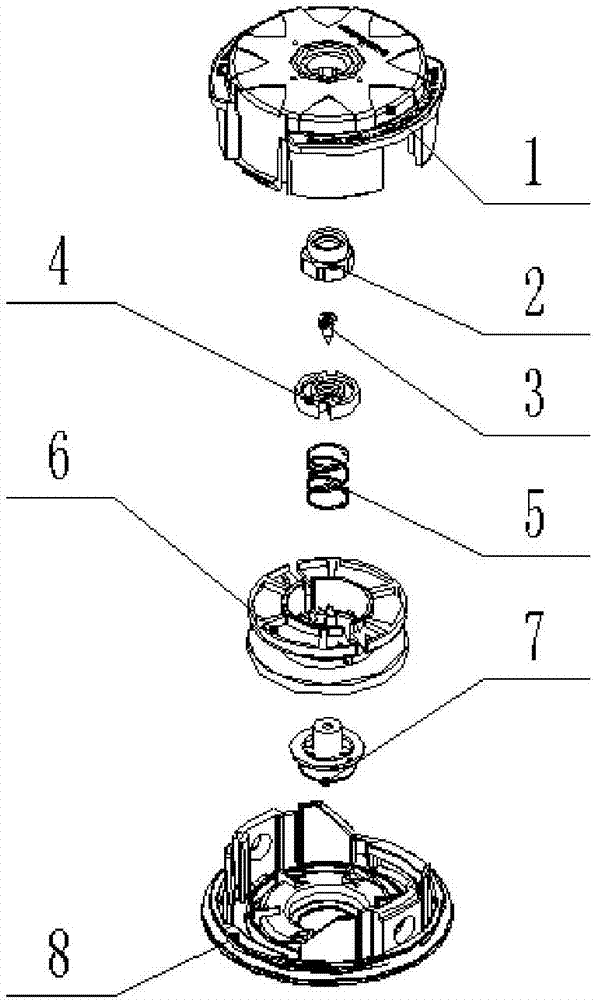

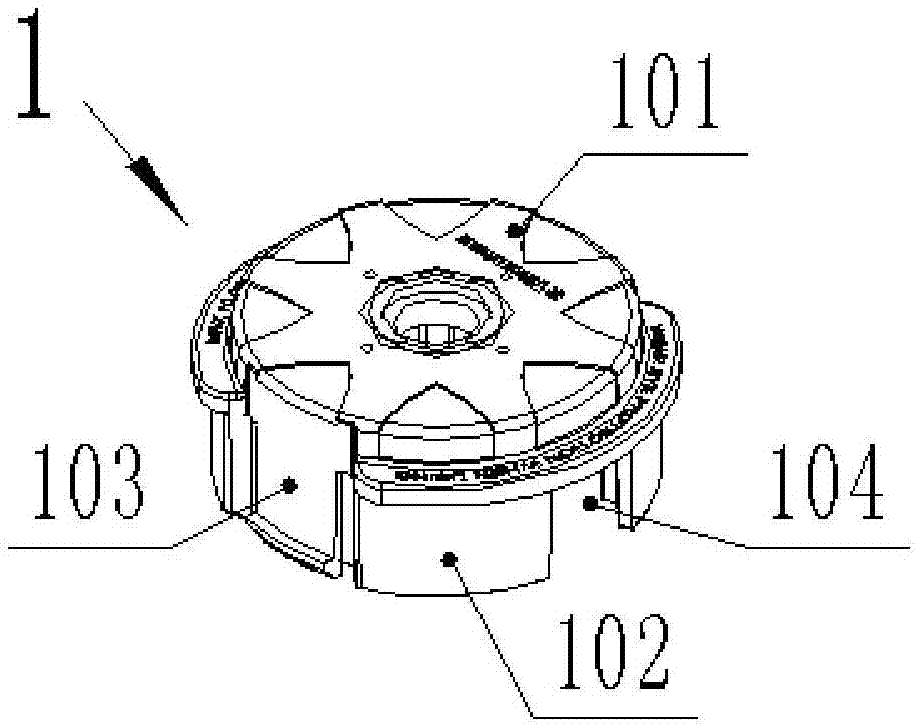

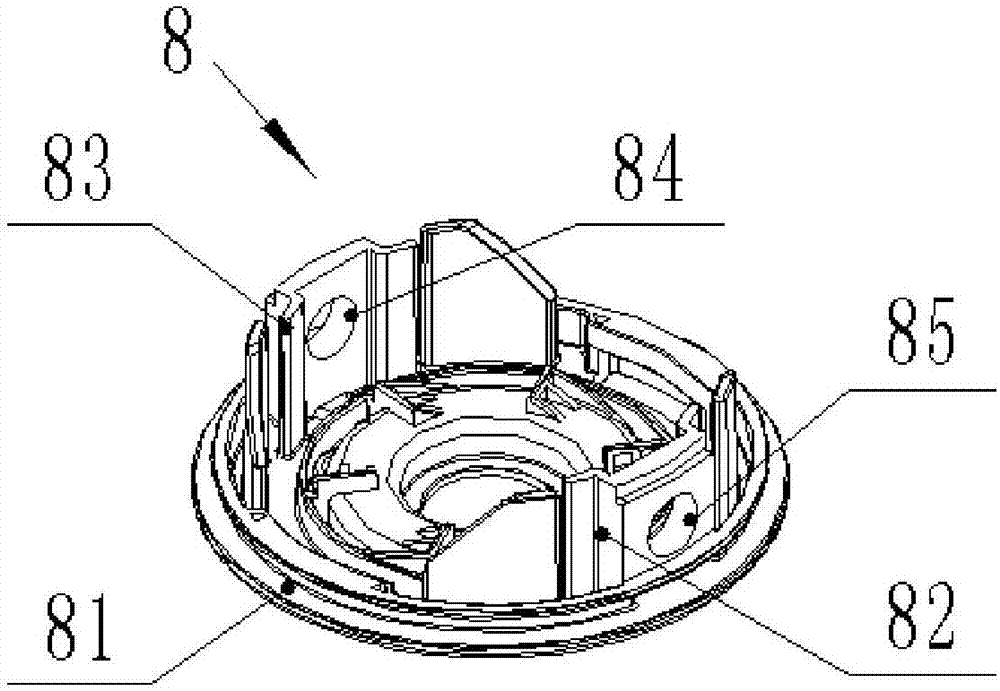

[0037] Such as figure 1 As shown in -3, this embodiment provides a connection structure, including a sheave box 1 and a large cover 8 that are interlocked from top to bottom, and a small cover 4 is also provided between the sheave box 1 and the big cover 8, and the small cover 4 A sheave 6 and a connecting block 7 are arranged between the big cover 8, a left-handed nut 2 is arranged between the small cover 4 and the sheave box 1, and the left-handed nut 2 is pressed on the sheave box 1, and the left-handed nut 2 and the sheave The box 1 has an interference fit; it also includes a rotary compression spring 5 and a self-tapping screw 3, the rotary compression spring 5 is set at the center of the sheave 6, the rotary compression spring 5 is sleeved on the raised structure of the connecting block 7, and the self-tapping screw 3 Through the small cover 4, the rotating compression spring 5 and the protrusion str...

Embodiment 2

[0049] Such as figure 1 As shown in -4, a grass trimming device provided by this embodiment includes the connection structure of the first embodiment above, a through hole is provided in the radial direction of the large cover 8, and a grass trimming rope 13 and two outlet ropes are also included. Clip 12, the rope-out clip 12 is respectively arranged on the outside of the through hole of the big cover 8, and the grass rope 13 passes through the rope clip 12, the big cover 8 and the rope clip 12 successively, and the grass rope 13 is arranged on the The bottom of the connecting block 7; the bottom of the connecting block 7 is also provided with an impact compression spring 9, a compression reed 10 and an impact head 11 from top to bottom, and the impact head 11 is locked with the bottom of the big cover 8, and the connection block 7 can Under the effect of stage clip 9, on the axial direction of big cover 8, bounce up and down vertically.

[0050] Specifically, the upper part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com