Overhead line plug-pull connection device

A connection device and overhead line technology, applied in the direction of connection, conductive connection, electrical component connection, etc., can solve the problems of operator injury, time-consuming and laborious, single-phase grounding of lines, etc., and achieve the effect of reducing emergency repair time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

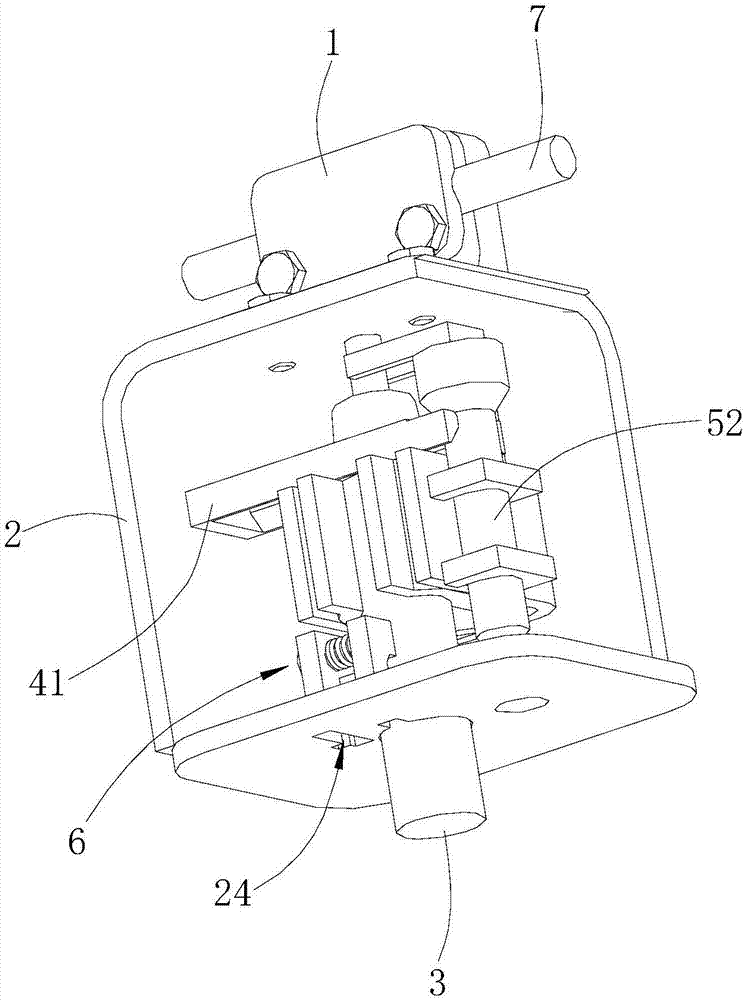

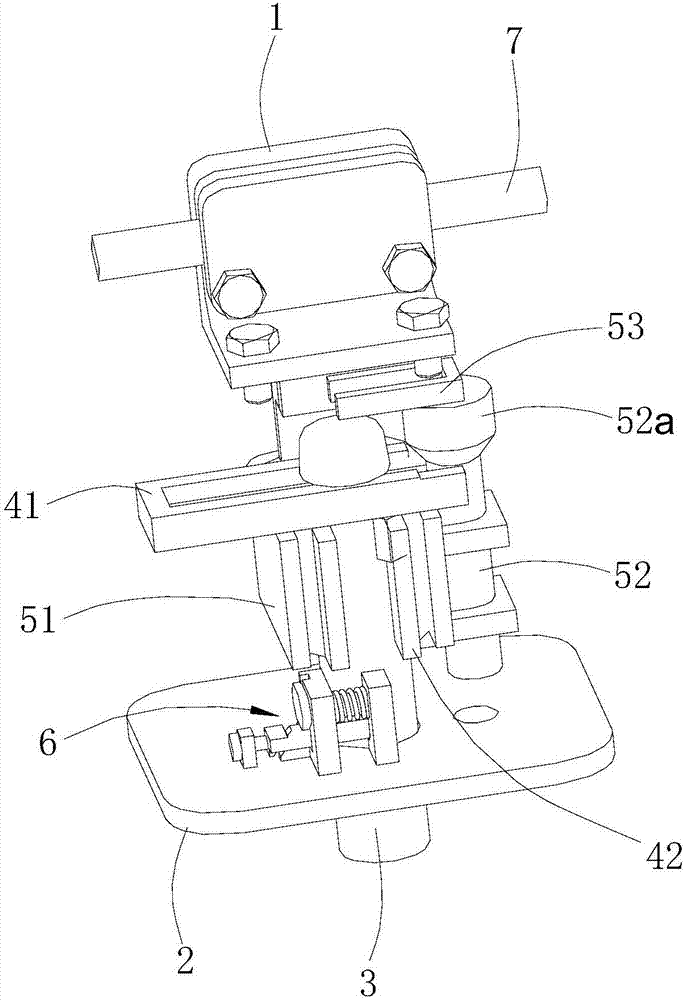

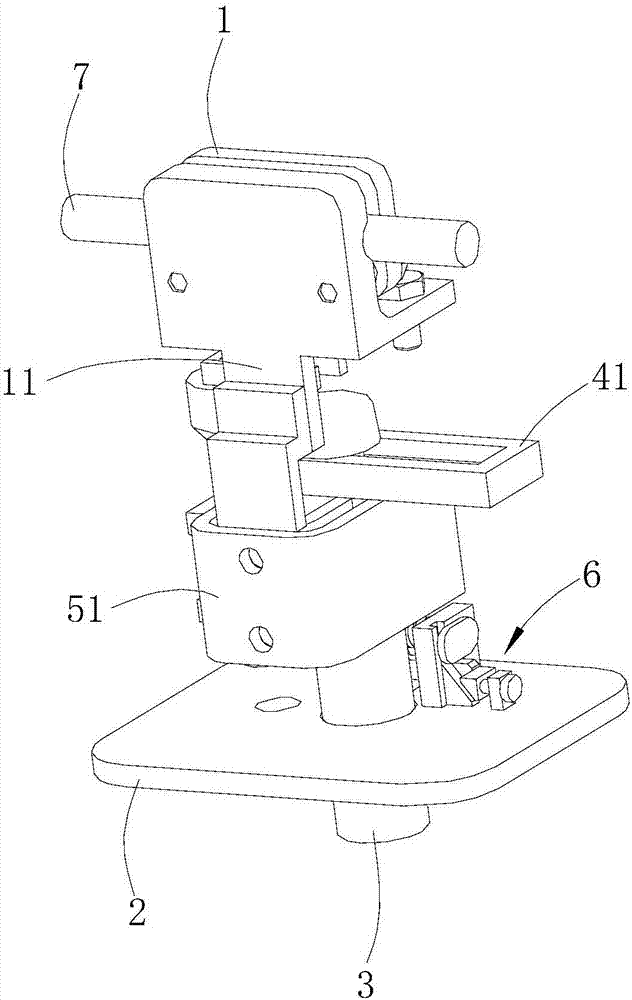

[0037] Such as Figures 1 to 11 Shown (in order to clearly understand the technical content of the present invention, Figure 1 to Figure 7 Part of the side wall of the insulating case 2 is omitted in the Figure 6 , Figure 7 only the bottom side walls of the insulating housing cavity are shown)

[0038] The connection device includes an insulating shell 2 , a wire clip, a connecting wire plug 3 , a clamping assembly, a wire withdrawing assembly and a locking assembly 6 .

[0039] The wire clip is the puncture wire clip 1, after the puncture wire clip 1 is hung on the power line 7, the bolt is tightened by an electric wrench, so that the puncture wire clip 1 is fixed on the power line 7, and the puncture wire clip 1 is fixed on the insulating shell 2 On the upper outer wall, the contact portion 11 of the piercing wire clamp 1 extends into the cavity of the insulating housing 2 .

[0040] The insulating housing 2 is provided with a cavity, and the lower end surface of the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com