Clamping fixing conical washer for multi-angle dispersion of electronic equipment panel load

A clamping and fixing technology for electronic equipment, which is applied in the field of clamping and fixing the combination of tapered gaskets and panels, can solve the problems of increasing the number of mounting holes of multi-layer panels of equipment and reducing the reliability of equipment mounting panels, so as to avoid electrochemical corrosion , Reduce wear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

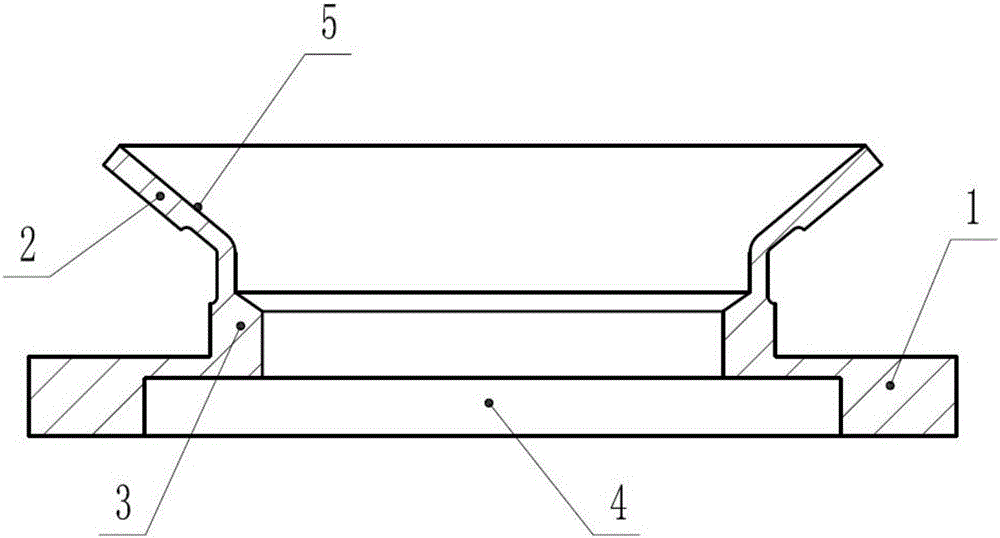

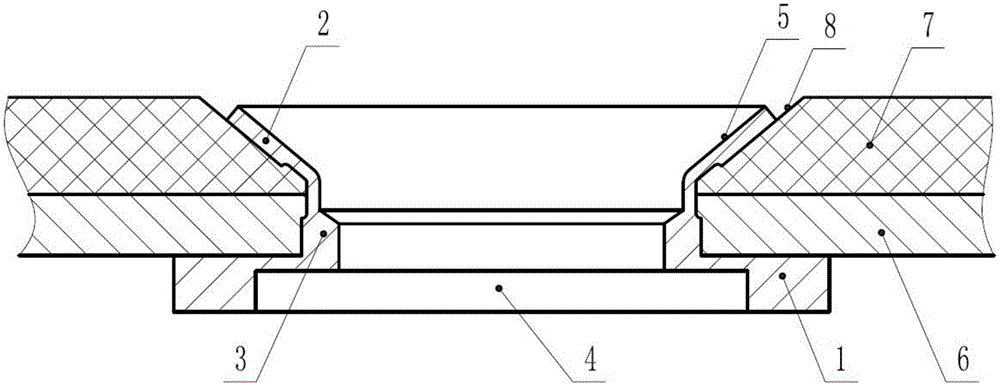

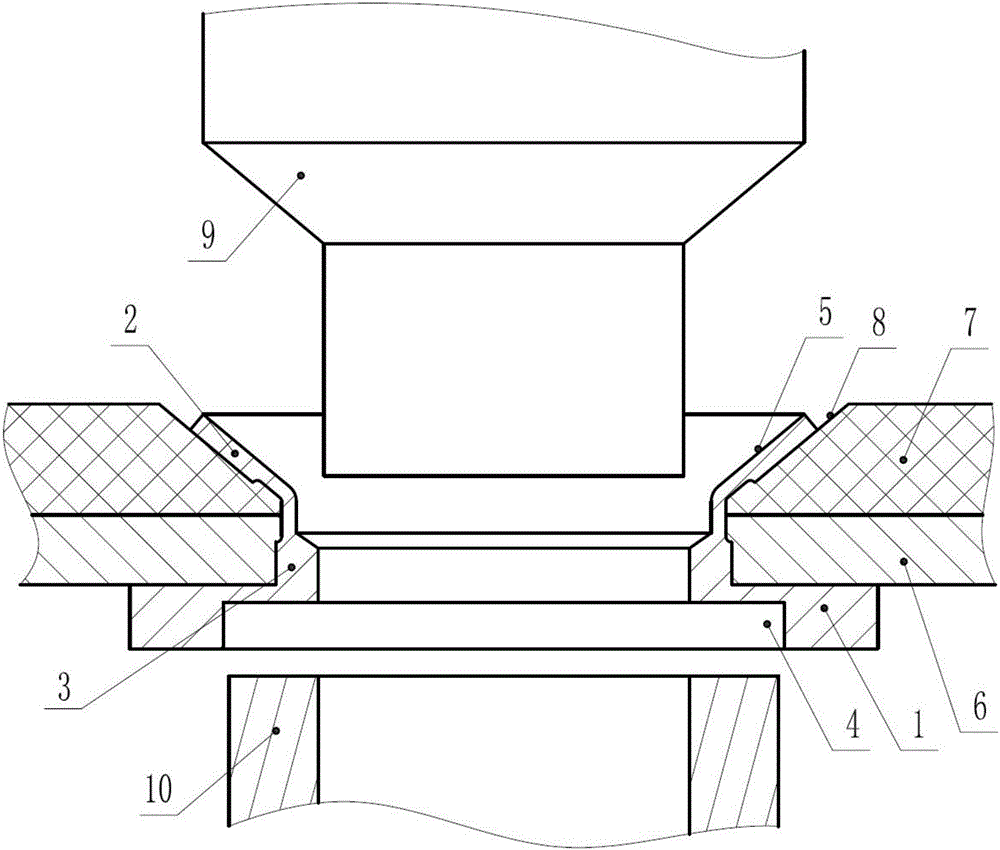

[0019] refer to figure 1 . In the embodiment described below, the clamping and fixing conical washer for distributing the load of the electronic equipment panel at multiple angles includes: a base 1 , a conical washer 2 , and a sleeve 3 . The bottom of the base 1 is equipped with a flat-bottomed circular counterbore 4 that is fitted with a round tubular tooling. The diameter of the sleeve 3 is smaller than the inner diameter of the flat-bottomed circular counterbore 4 and is integrally connected with the base 1. It extends upward to connect the conical washer 2. A notch is formed on the outer surface of the outer surface of the cone of the face washer 2 that is docked with the sleeve 3, and the inner surface of the bevel washer 2 is a conical counterbore 5 for installing a countersunk fastener for electronic equipment.

[0020] By adjusting the relevant dimensions of the base and the sleeve, it can be applied to equipment installation panels with different thicknesses and dif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com