Sucker rod anti-eccentric grinding device for coal-bed gas well

A technology for coalbed methane wells and sucker rods, which is applied to drill rods, drilling equipment, earth-moving drilling, etc., can solve the problems of short service life, large friction coefficient and large friction force of centralizers, so as to prolong service life and reduce frictional resistance. , the effect of improving working hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

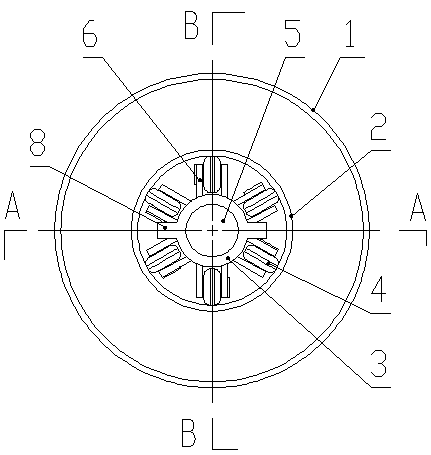

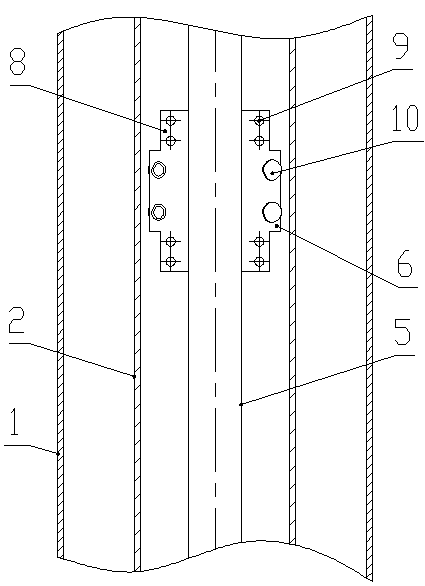

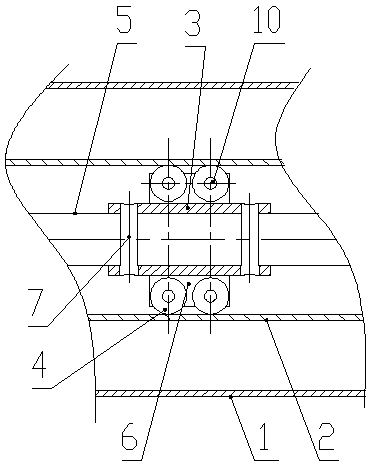

[0017] Such as figure 1 , figure 2 and image 3 As shown, the anti-eccentric wear device for sucker rods for coalbed methane wells of the present invention includes a centralizing mechanism, and the center of the centralizing mechanism is provided with a mounting hole for inserting the sucker rod 5, and the outer circumference of the centralizing mechanism is uniformly provided with several For the rollers 4, the plane where the direction of rotation of each roller 4 passes through the centerline of the centralizing mechanism, and the outer surfaces of all the rollers 4 are located on the same circle.

[0018] There are two layers of rollers 4 in the middle of the righting mechanism, and there are six rollers 4 on each layer. The rollers 4 on the upper layer and the lower layer are in one-to-one correspondence, and every two corresponding rollers 4 are set on the righting mechanism through a bracket 6 Above, a water flow channel is formed between adjacent brackets 6 .

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com