Forming method for end enclosure structure and lining of IV-type cylinder

A molding method and lining technology, which is applied to household components, household appliances, and other household appliances, can solve the problem that the extrusion blow molding parison cannot pass through the pole hole of the metal insert, so as to reduce the risk of falling off and failure The effect of low risk and good sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

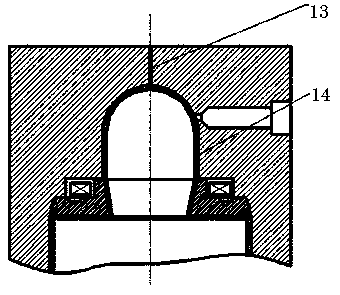

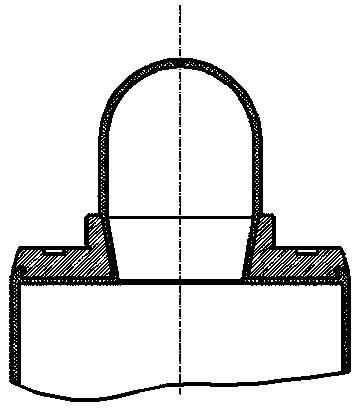

[0025] Embodiment 1: see Figure 6 , a gas cylinder head lining structure, including a metal end cap 1, a metal insert 2, a plastic liner 4 and a sealing assembly, a sealing assembly is arranged between the metal insert 2 and the metal end cap 1, the A plastic lining 4 is provided under the metal insert 2, and a carbon fiber composite layer 3 is wound around the metal end cap. The metal insert 2 and the metal end cap 1 form an integral head. The rigidity of the head is good, which is conducive to reducing the amount of carbon fiber in the head section. The combination of lining and metal parts, the lining can be made into a multi-layer structure by blow molding technology, which is used to block small molecular gases.

Embodiment 2

[0026] Example 2: see Figure 6 , as an improvement of the present invention, the sealing assembly includes a first sealing ring 5, a second sealing ring 6 and a third sealing ring 7, the first and second sealing rings have a circular cross-sectional shape, and the material is rubber, The cross-sectional shape of the third sealing ring is set to be rectangular, and the material is rubber or silicone resin. The first sealing ring and the second sealing ring are arranged on the side of the metal end cap. As the metal end cap is tightened, the sealing ring is compressed; the double-layer protective gas does not leak, and the third sealing ring is arranged on the metal insert The connection between the upper part and the metal end cap prevents the failure of the first sealing ring and the second sealing ring, and at the same time prevents external resin, etc. from flowing into the thread gap. When the end cap is assembled, the inner liner assembly of the gas cylinder has a comple...

Embodiment 3

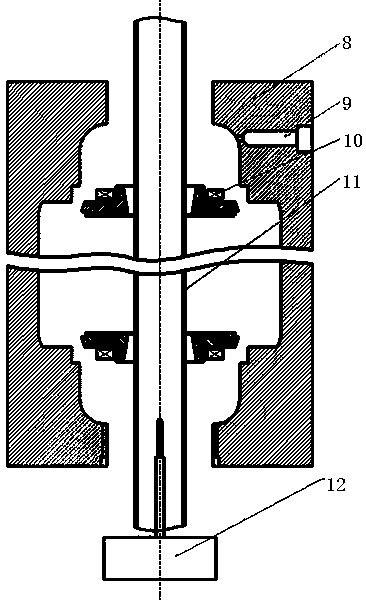

[0027] Embodiment 3: see Figure 1-Figure 5 , a type IV gas cylinder head structure and lining molding method, the method may further comprise the steps:

[0028] 1) The manipulator clamps the upper and lower metal inserts and places them at the corresponding positions in the mold, the billet is extruded, and the lower end of the billet passes through the pole holes of the upper and lower metal inserts;

[0029] 2) The mold is closed.

[0030] 3) The bottom blowing needle seat supplies air, blows the parison, and the parison blow molding is completed. The blowing needle in the upper blowing needle hole pierces the blow molding dummy, forming an air flow channel inside the parison, and the blowing needle seat Convective heat exchange cooling inside the mold with the blowing needle holes on the upper end, cooling to an appropriate temperature, opening the mold, removing the parison with inserts, cutting off the blow molding flash, and then cooling and shaping;

[0031] 4) Plac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com