Walking beam furnace

A walking heating furnace and heating chamber technology, applied in the direction of lighting and heating equipment, furnace, furnace type, etc., can solve the problems of affecting heating efficiency, transportation confusion, easy to change the distance between steel pipes, etc., and achieve the effect of reducing heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings.

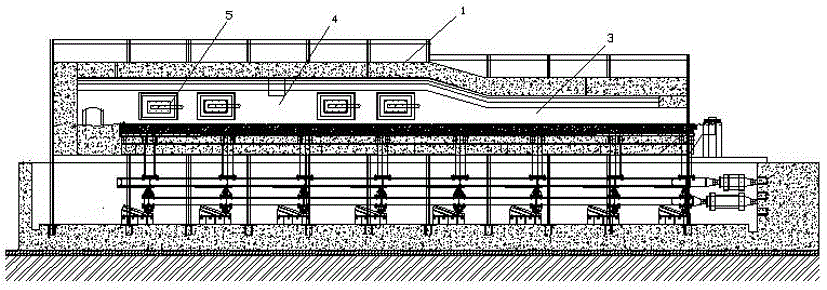

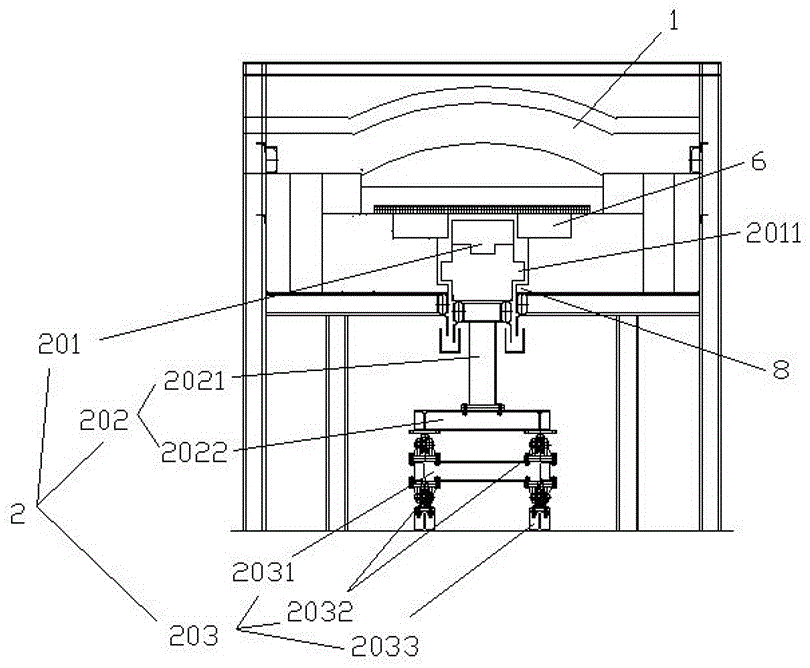

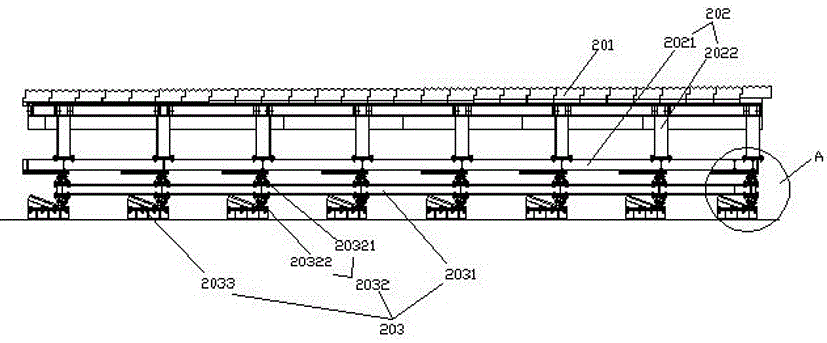

[0025] Such as Figure 1 to Figure 4 As shown, the embodiment of the present invention includes a furnace body 1 and a conveying device 2. In the furnace body 1, a preheating chamber 3 and a heating chamber 4 connected to each other are sequentially arranged along the feeding direction to the discharging direction. The height of the preheating chamber 3 is less than The height of the heating chamber 4. The inner wall of the furnace body 1 is made of fireproof material. The conveying device 2 passes through the preheating chamber 3 and the heating chamber 4. A heating device 5 is arranged in the heating chamber 4. The heating device 5 is arranged above the conveying device 2. The heating device 5 is mainly realized by means of a hot air blower. The conveying device 2 at least includes a conveying platform 201, a translation mechanism 202 that moves the conve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com