Full-automatic self-adaptive aligning and plugging mechanism for throats of large cavity type workpieces

A fully automatic and self-adaptive technology, applied in the direction of using liquid/vacuum for liquid tightness measurement, etc., can solve the problems of small and dark interior space, low efficiency, hidden safety hazards, etc., to optimize structural design, reduce cost requirements, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

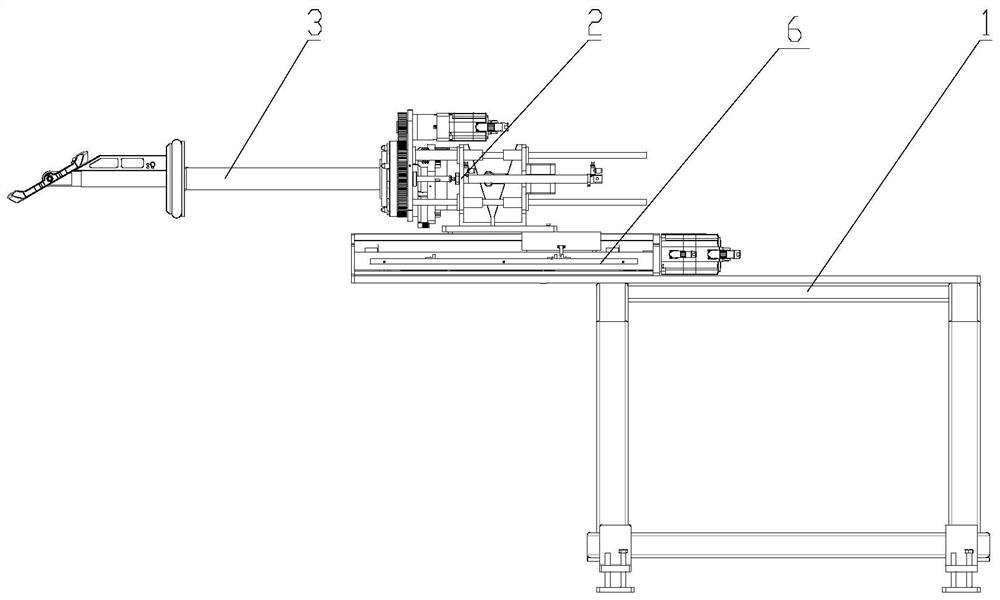

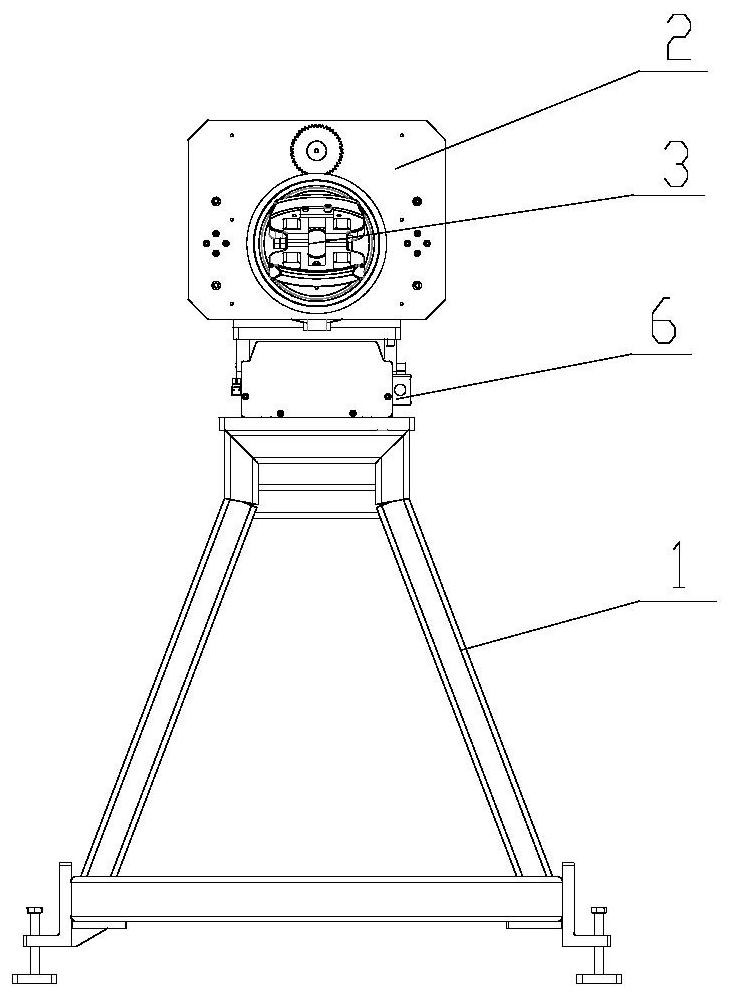

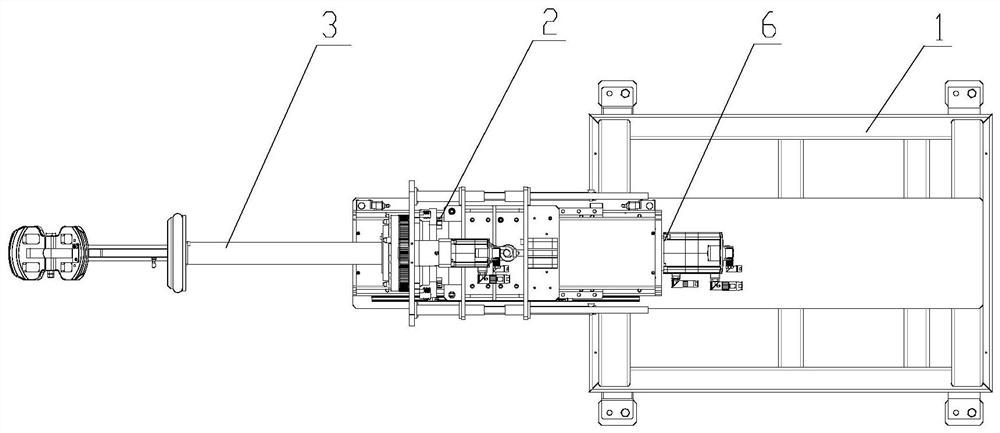

[0037] like Figure 1-3 As shown, the present invention provides a fully automatic self-adaptive aligning and blocking mechanism for the throat of large-scale cavity workpieces, including a base 1, a driving mechanism 2, a blocking mechanism 3 and a horizontal transfer module 6, wherein the horizontal The transfer module 6 is arranged on the base 1; the driving mechanism 2 is arranged on the horizontal transfer module 6; the blocking mechanism 3 is arranged on the output end of the driving mechanism 2; The throat of cavity type workpiece A is blocked.

[0038] like Figure 4 As shown, in the embodiment of the present invention, the base 1 includes a frame 4 and an anchor 5 arranged at the bottom of the frame 4, the frame 4 is connected to the gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com