Flow regulating agent particles, flow regulating agent, and preparation method and application of flow regulating agent

A technology of flow regulating agent and particles, which is applied in chemical instruments and methods, mining fluids, earth drilling and mining, etc. It can solve the problems of small sweep volume and difficulty in deep stratum flow regulation, and achieve strong salinity resistance and expansion Effect of water flooding on swept volume and good temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0054] In a third aspect, the present invention provides a method for preparing the above-mentioned flow regulator, the method comprising the following steps:

[0055] (1) Add viscoelastic main agent, selective co-solvent, density regulator, expansion agent, and optional toughening agent in sequence to mix, and obtain the mixture after fully stirring;

[0056] (2) extruding the mixture obtained in step (1) to obtain flow regulator particles;

[0057] (3) Mixing the flow regulating agent particles obtained in step (2) with the carrier liquid to obtain the flow regulating agent.

[0058] The inventors of the present invention found in the research that mixing the viscoelastic main agent, selective co-solvent, density modifier, expansion agent and optional toughening agent in the order of adding in order can further improve the final oil recovery. Yield and ability to seal cracks.

[0059] In the preparation method of the present invention, step (2) may also include shearing an...

Embodiment 1

[0083] (1) Add 60 parts by weight of polyethylene, 30 parts by weight of C5 petroleum resin, 2 parts by weight of fly ash, 5 parts by weight of anionic polyacrylamide, and 3 parts by weight of man-made chopped fibers, and fully stir and mix for later use;

[0084] (2) The temperature of the twin-screw extruder is raised to 160°C, and the mixed composite material is slowly poured into the twin-screw extruder for extrusion;

[0085] (3) Cut the extruded material to 1-2mm particles by using a mechanical shearer, and round them to obtain flow regulator particles. Various properties of the flow regulator particles were measured, and the results are shown in Table 1.

[0086] The density is 1.07g / cm 3 The carrier liquid and the flow regulator particles are mixed at a weight ratio of 80:20 to prepare the flow regulator, wherein, based on the total weight of the carrier liquid, the carrier liquid contains 0.1% by weight of hydroxysultaine, and also contains water and is used to adjus...

Embodiment 2

[0088] (1) Add 70 parts by weight of polystyrene, 20 parts by weight of C9 petroleum resin, 3 parts by weight of fly ash, 5 parts by weight of cross-linked carboxymethyl cellulose, and 2 parts by weight of man-made short-cut fiber, fully stir and mix for later use ;

[0089] (2) The temperature of the twin-screw extruder is raised to 180°C, and the mixed composite material is slowly poured into the twin-screw extruder for extrusion;

[0090] (3) Cut the extruded material to 2-3mm particles by using a mechanical shearing machine, and round them to obtain flow regulator particles. Various properties of the flow regulator particles were measured, and the results are shown in Table 1.

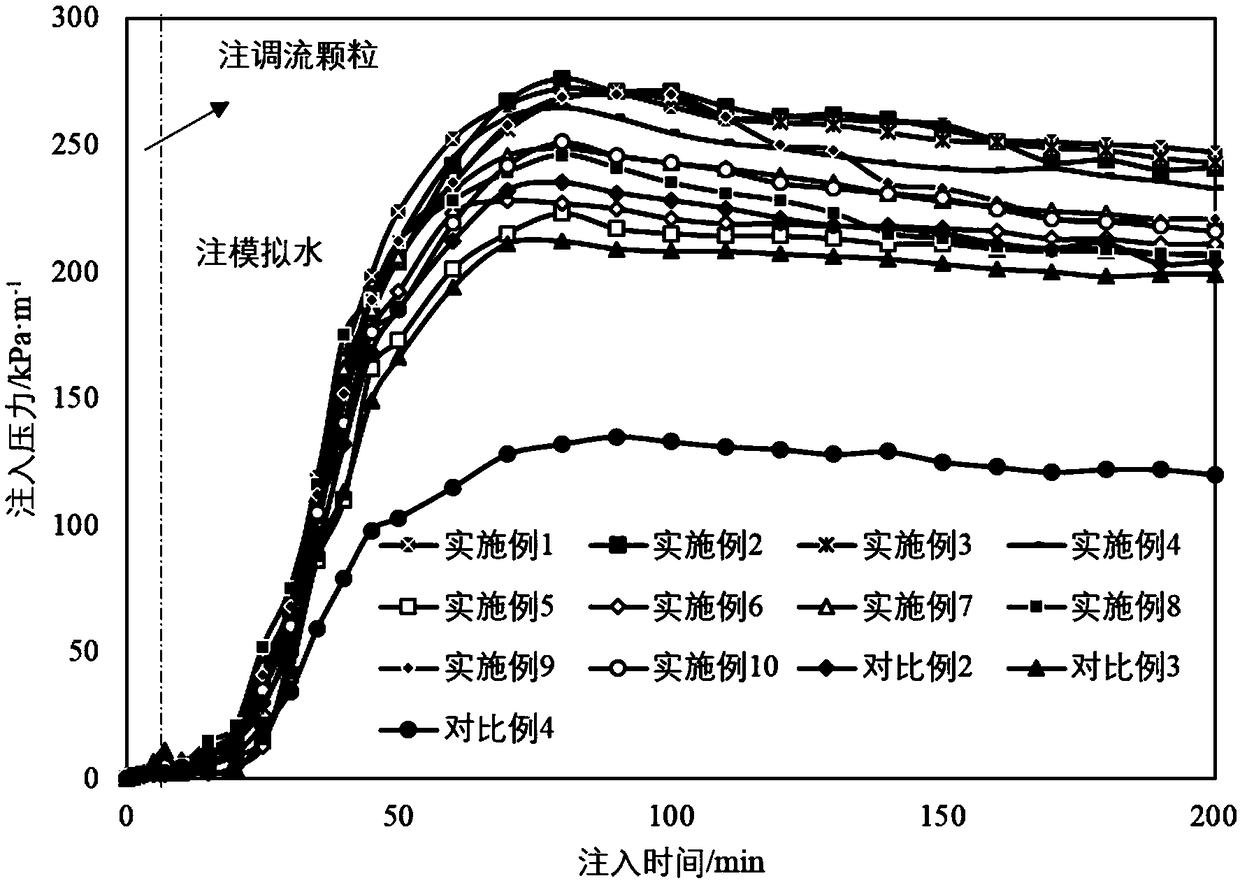

[0091] The density is 1.09g / cm 3 The carrier fluid and the flow regulator particles are mixed in a weight ratio of 80:20 to prepare the flow regulator (such as figure 1 shown), wherein, based on the total weight of the carrier liquid, the carrier liquid contains 0.1% by weight hydroxysultaine, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com