Mould for in-mould decoration (IMD), shell, preparation method thereof, and mobile terminal

A technology of in-mold injection molding and mobile terminals, which is applied in the field of materials and can solve problems such as in-mold injection molds that need to be improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiments of the invention are described in detail below, examples of which are illustrated in the accompanying drawings. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

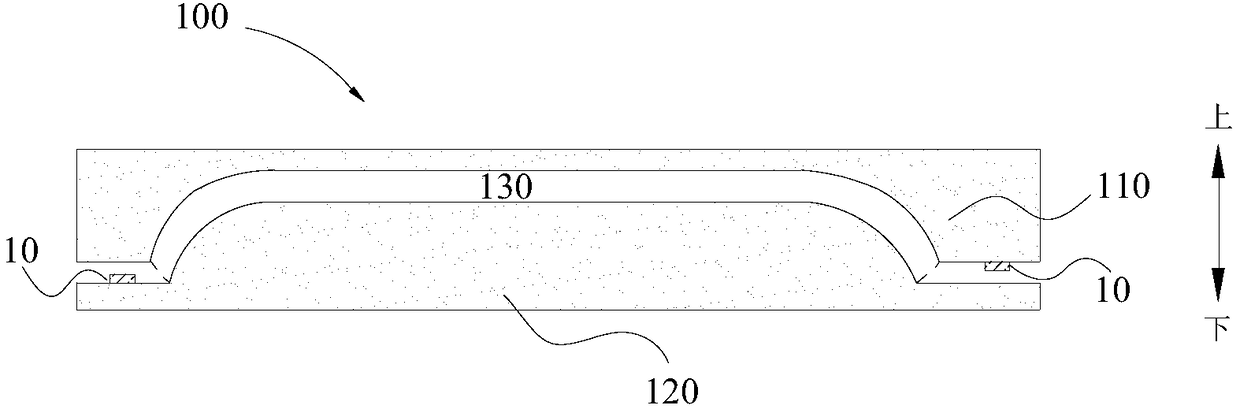

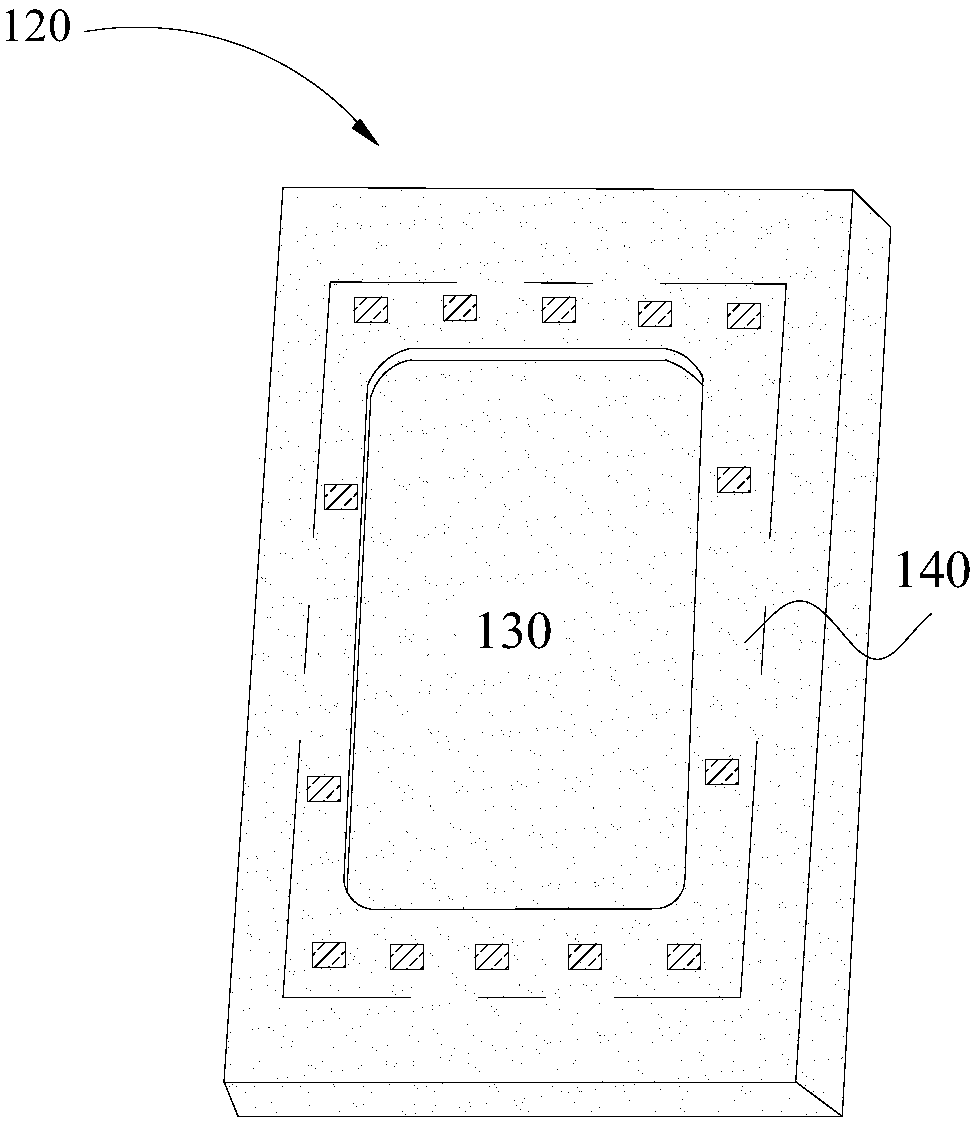

[0022] In one aspect of the invention, the invention proposes a mold for in-mold injection molding. According to an embodiment of the present invention, refer to figure 1 as well as figure 2 , the in-mold injection mold 100 includes: the mold includes: an upper mold 110 and a lower mold 120 . Wherein, the injection molding space 130 is defined between the upper mold 110 and the lower mold 120, and an external positioning area 140 (refer to figure 2 ). Moreover, at least one of the upper mold 110 and the lower mold 120 has a die positioning member 10 disposed on the outer positioning area. Thereby, it can be ensured that the injection diaphragm does not mov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com