Automatic steel bar lap joint and welding device

A technology for welding devices and steel bars, which is applied in the direction of auxiliary devices, welding equipment, welding equipment, etc., to achieve the effects of convenient operation, fast welding speed and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

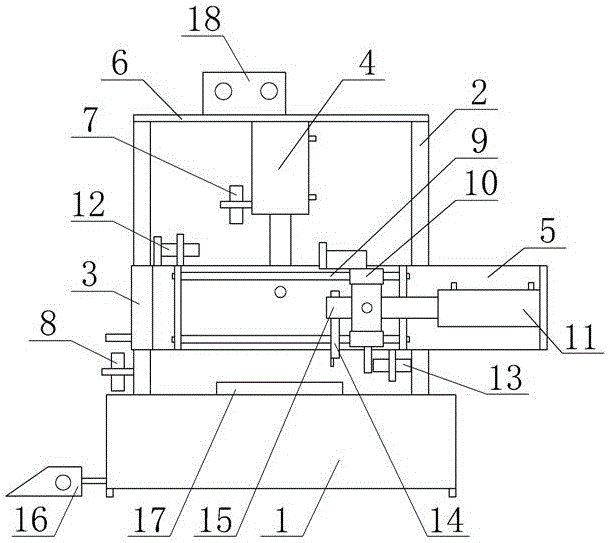

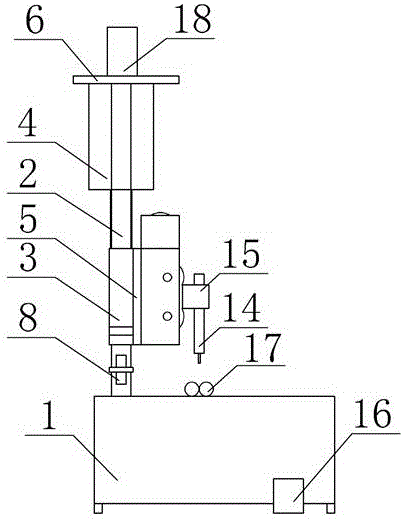

[0010] Below in conjunction with embodiment and accompanying drawing, the present invention is described in further detail:

[0011] Two lifting sliding columns 2 are fixed on the base 1, and a lifting sliding sleeve 3 is set outside the lifting sliding columns 2. The upper ends of the lifting sliding columns 2 are connected with a fixing plate 6, and a power distribution box 18 is arranged on the fixing plate 6. Using the connecting plate 5 Connect the two lifting sliding sleeves 3 to each other and extend to the right side, respectively fix the traverse slide bar 9 on the upper and lower sides of the connecting plate 5, and install the left limit switch 12 on the connecting plate 5 on the left upper part of the traverse slide bar 9, Right limit switch 13 is installed on the connecting plate 5 of traversing slide bar 9 right bottoms, the fixed end of lift cylinder 4 is fixed below the center of fixed plate 6, upper limit switch 7 is installed on the left side of lift cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com