Heat transfer side kneading welding heat exchanger with headers and double dividing walls and manufacturing process of heat transfer side kneading welding heat exchanger

A technology of heat exchangers and headers, applied to indirect heat exchangers, heat exchanger types, heat exchanger shells, etc., can solve the problems of low heat exchange efficiency, small heat transfer area, poor effect, etc., and achieve flow resistance Small size, good heat transfer, and increased heat transfer area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

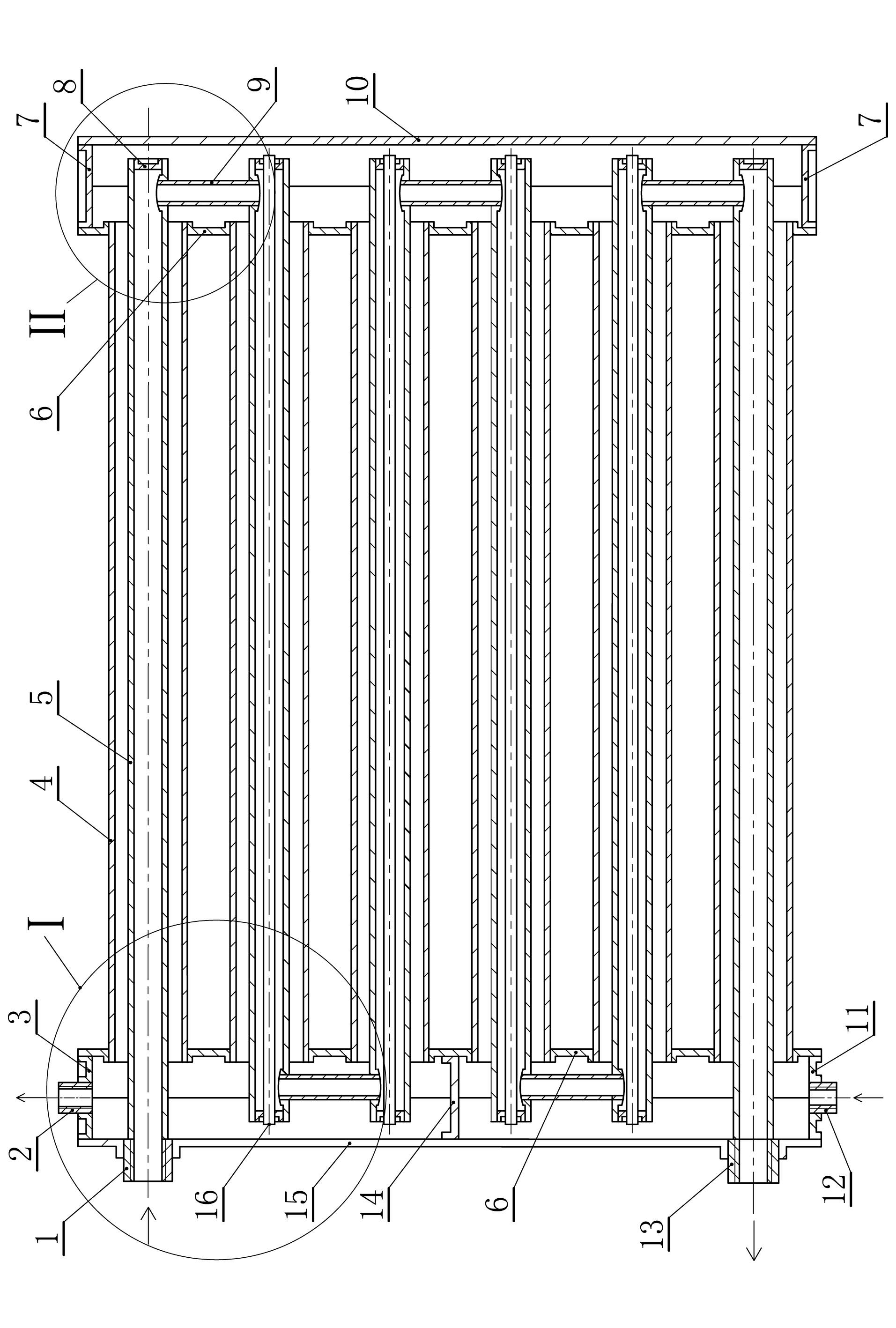

[0069] In this embodiment, the header is a round tube header as an example to further illustrate the present invention:

[0070] The double-wall heat transfer kneading edge welding heat exchanger of the round tube header of the present invention and its manufacturing process include: two headers, two or more tap water communicating outer pipes are connected between the two headers; and the feature is :Tap water is connected to the outer pipe with a heating heating pipe, and the inner pipe is inserted into the heating heating pipe to form a double-row channel and double-walled heat transfer. The heating pipe is connected, and the beginning of the connecting is the heating inlet and the other end It is the heating outlet. The heating inlet and the heating outlet are connected to the upper and lower parts of the side wall of one end of the header, and the tap water inlet and the tap water outlet are connected to the upper and lower parts of the same header block (end cover).

[0071]...

Embodiment 2

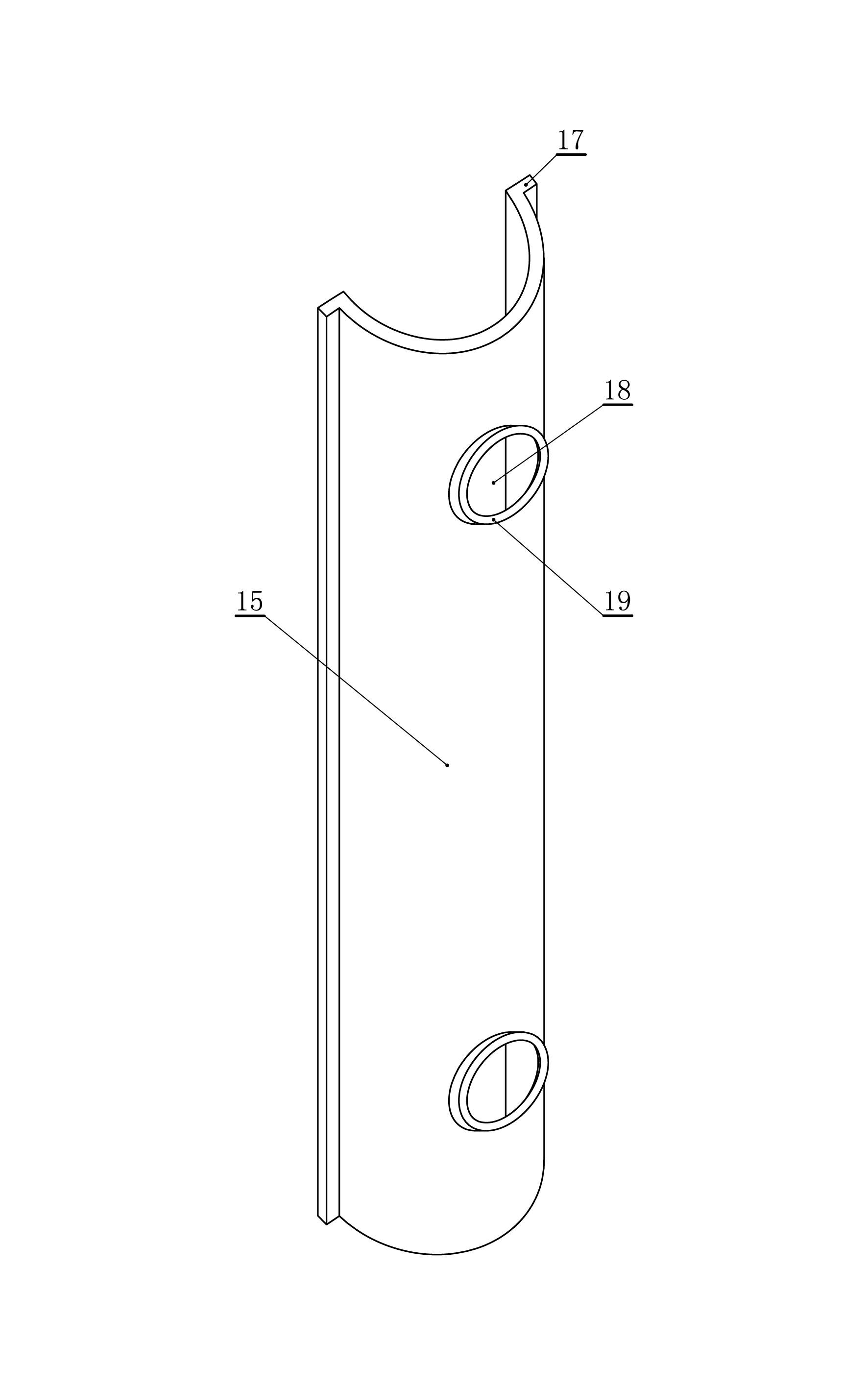

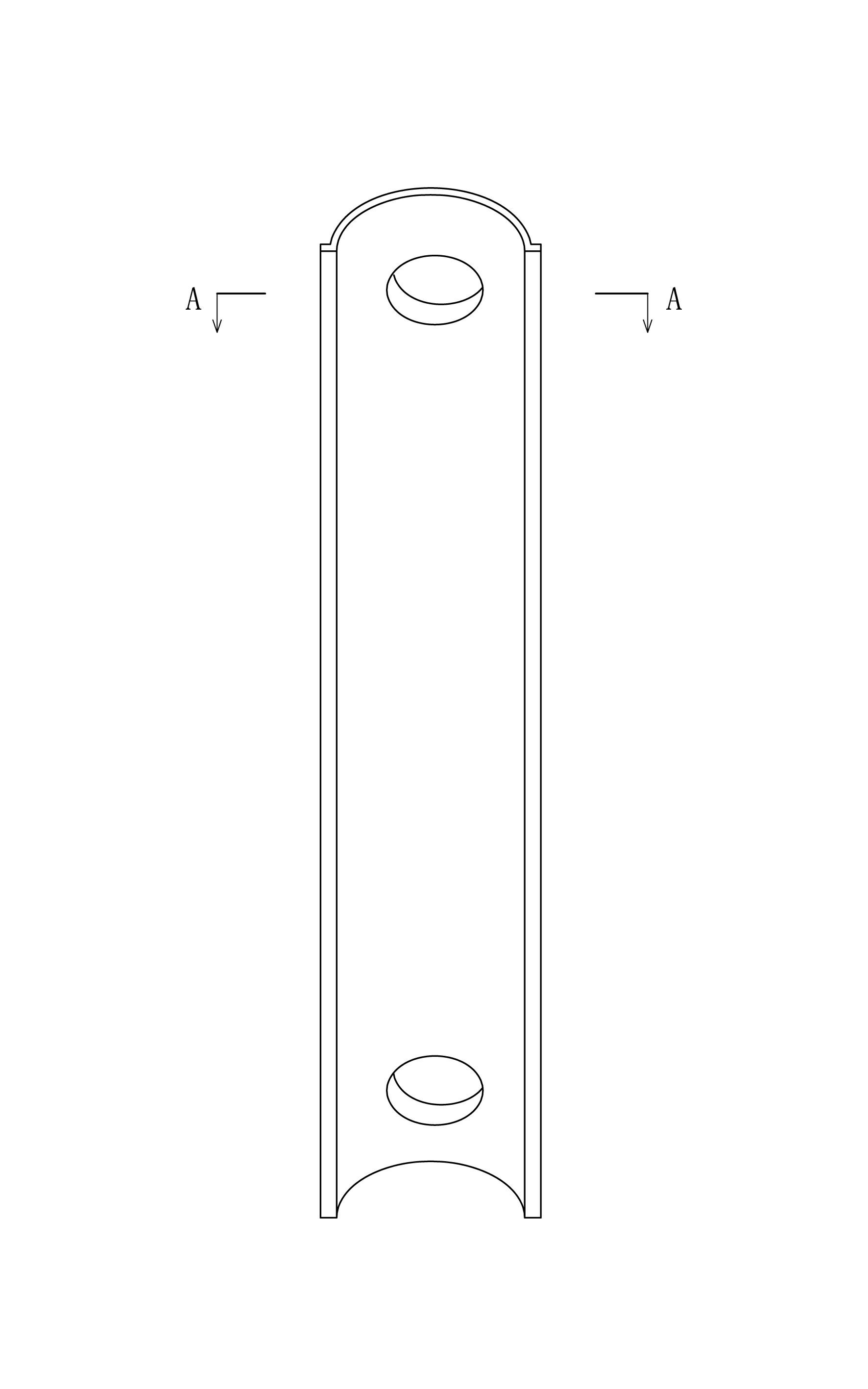

[0081] In this embodiment, the header is a D-shaped header as an example to illustrate the present invention.

[0082] 1. The center hole of the orifice plate of the D-shaped header is punched according to the diameter of the outer pipe connected to the tap water. The height of the hole is 2~2.5mm, and the height of the two sides of the orifice is 2~3mm. The C-shaped plate is strengthened by pressing There are 4 ribs, the tap water connecting outer pipe is inserted into the drawing hole of the D-shaped header orifice plate without gaps, and the drawing hole edge of the orifice plate is consistent with the tap water connecting outer pipe port edge, and the kneading edge self-fusion flat welding method is connected by circumferential seam welding. The heating pipe is connected to the straight pipe for heat supply. After the inner pipe of the tap water heat absorption is connected, the whole is movable. The heat expansion and contraction can expand freely, reducing the water leakage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com