Brazing process of turbine stator blade of gas turbine

A gas turbine and brazing technology, which is applied in manufacturing tools, welding equipment, welding equipment, etc., to reduce the number of re-brazing, improve repairability and service life, and reduce defects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with specific embodiment, technical content of the present invention is elaborated:

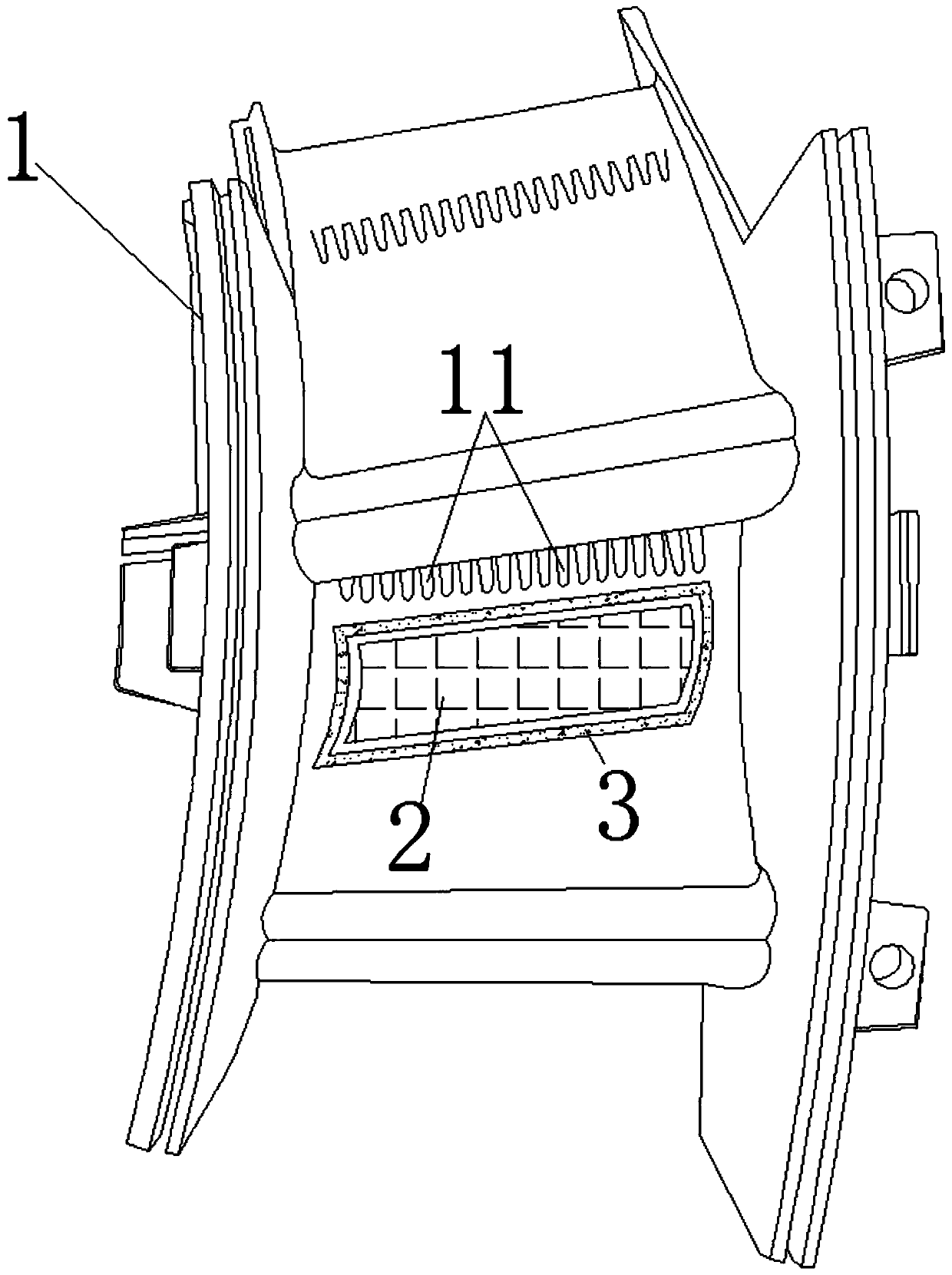

[0028] A coating thermal spraying process for gas turbine turbine moving blade blades, for GE MS9001 E model gas turbine part of the first stage stator blade 1 such as figure 1 As shown, the welding method of vacuum furnace brazing is used to ensure that the wall thickness error after brazing, welding and grinding can be controlled within 0.5 mm, including the following process steps:

[0029] a. Surface pretreatment: Firstly, the cracks on the vanes of the stator blades are detected by the FPI flaw detection method, and then the detected penetrating cracks are repaired by argon arc welding, and the detected small cracks are removed by grinding After the repaired and polished area is inspected by the FPI flaw detection method, it will enter the next process;

[0030] b. Welding small squares: Thickness detection is performed on the crack repair area in the qualifi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com