Pile foundation defect detection and repair method for cast-in-situ bored pile

A technique for bored cast-in-place piles and defects, which is applied in the repair of foundation structures, sheet pile walls, foundation structure engineering, etc., and can solve problems such as inability to determine broken piles or holes, poor detection results, and missed inspections of holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

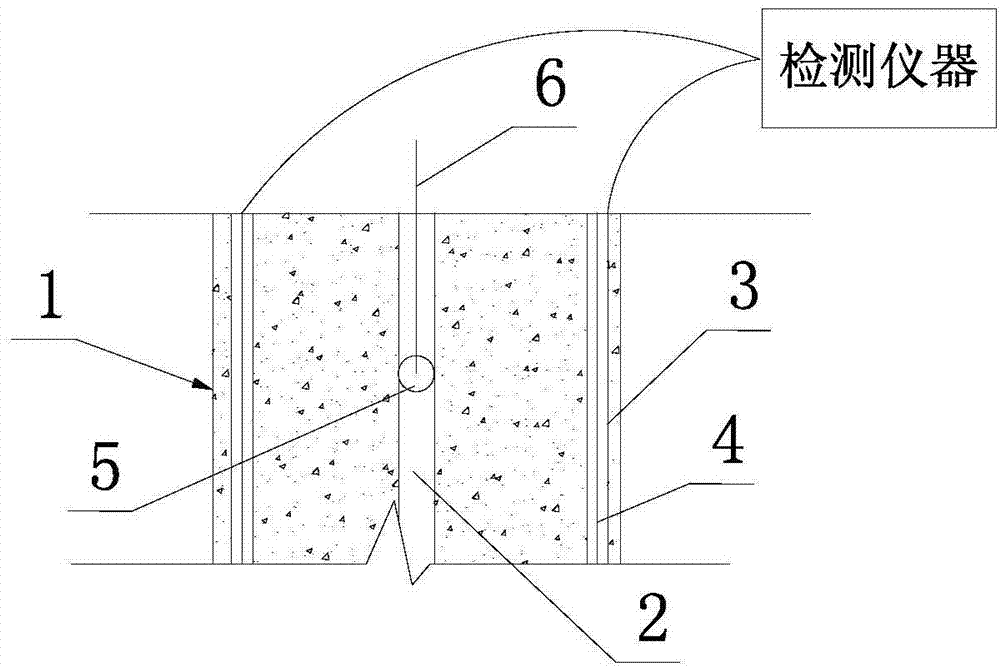

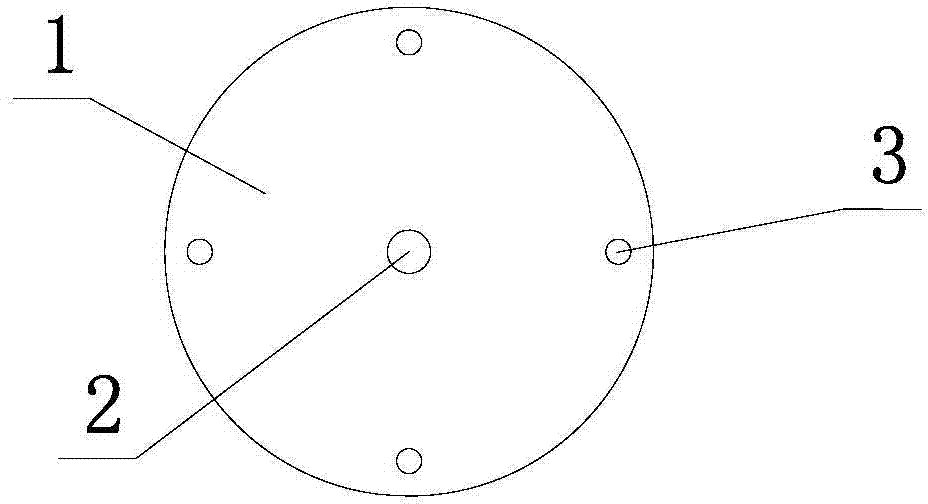

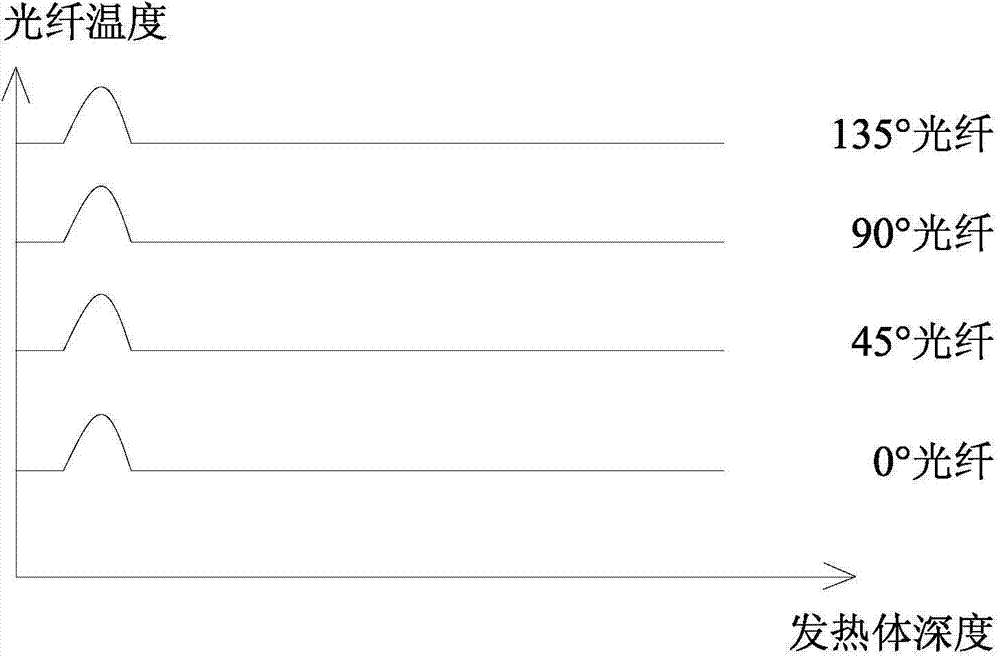

[0025] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, the detection and repair method of the pile foundation defect of the bored pile of the present invention, its steps are as follows.

[0026] a. When pouring bored piles, reserve a central vertical hole 2 and several edge vertical holes 3, all edge vertical holes 3 are located on the same circumference and are evenly distributed along the circumferential direction, the central vertical hole 2 and edge vertical holes 3 all run through the whole pile body 1. When pouring bored piles, a plurality of vertical sleeves are pre-embedded, and then pulled out after pouring to form each edge vertical hole 3 and central vertical hole 2 . In this embodiment, four edge vertical holes 3 are provided, and their circumferential positions are respectively 0°, 45°, 90° and 135°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com