Laser no-filling penetration weld seal welding process for T-shaped welding head of steel plate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] In order to make the content of the present invention easier to understand clearly, the present invention will be described in further detail below according to specific embodiments in conjunction with the accompanying drawings,

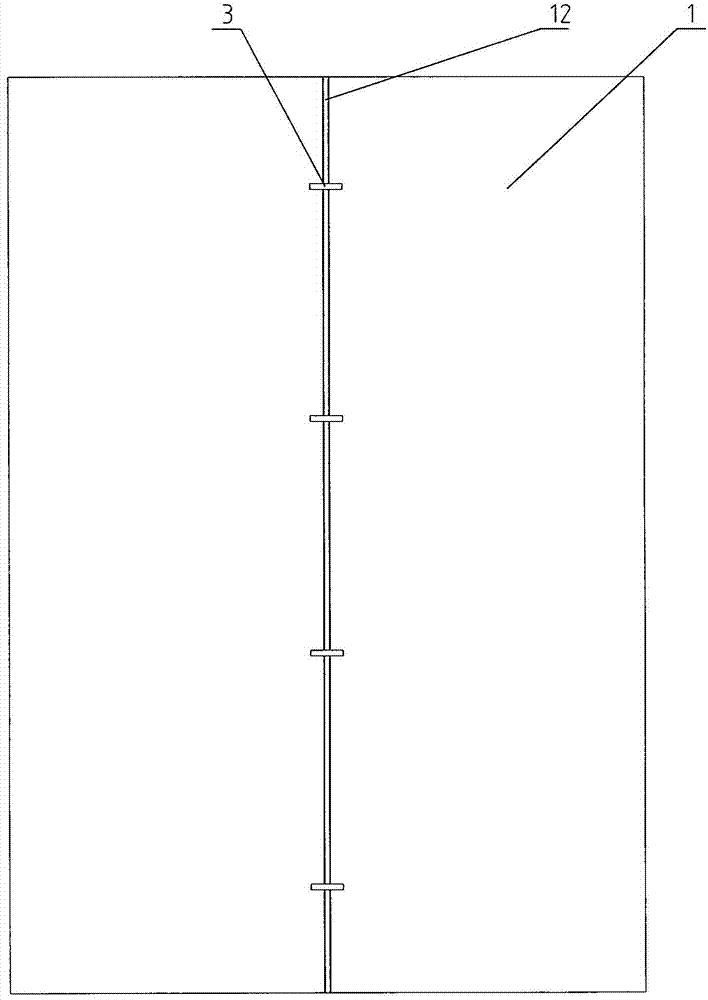

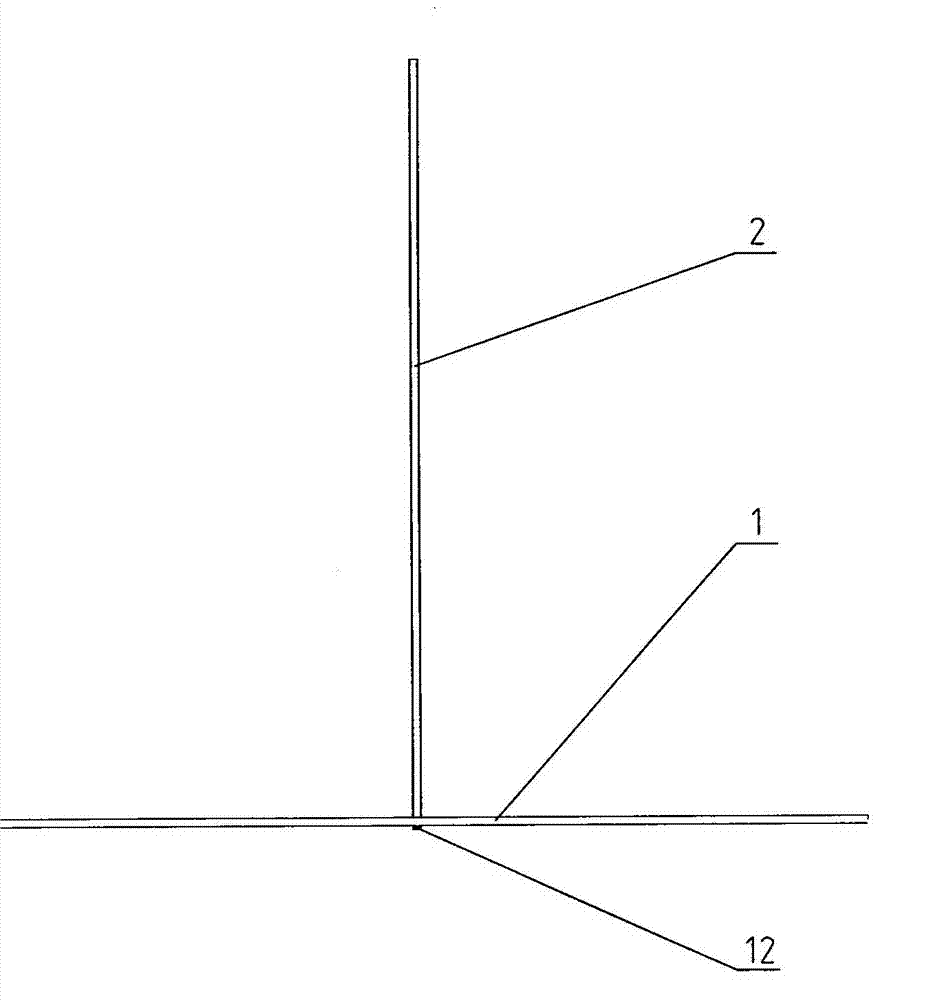

[0010] Such as figure 1 , 2 As shown, a laser non-filling penetration welding sealing welding process of a steel plate T-shaped welding head, the steps of the process are as follows: use a laser welder to weld the first workpiece 1 and the second workpiece 2 from the back of the first workpiece 1 Carry out laser penetrating welding without filling at seam overlap to form weld seam 12; perform laser penetrating welding without filling four times in the vertical direction of weld seam 12 to form four vertical weld seams 3 perpendicular to weld seam 12, and adjacent There is an interval between the vertical welds 3; carry out weld leak detection on the weld 12, and when a weld leak is found, manually repair the weld 12 between the adjacent verti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com