Brazing method of high-volume-fraction silicon carbide particle reinforced aluminum matrix composite material and aluminum-silicon alloy

A technology of silicon carbide particles and high volume fraction, applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of poor performance of welding joints and failure to meet the requirements of electronic packaging shells, so as to achieve beautiful weld seams and avoid self- The roughness of the organization and the effect of simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

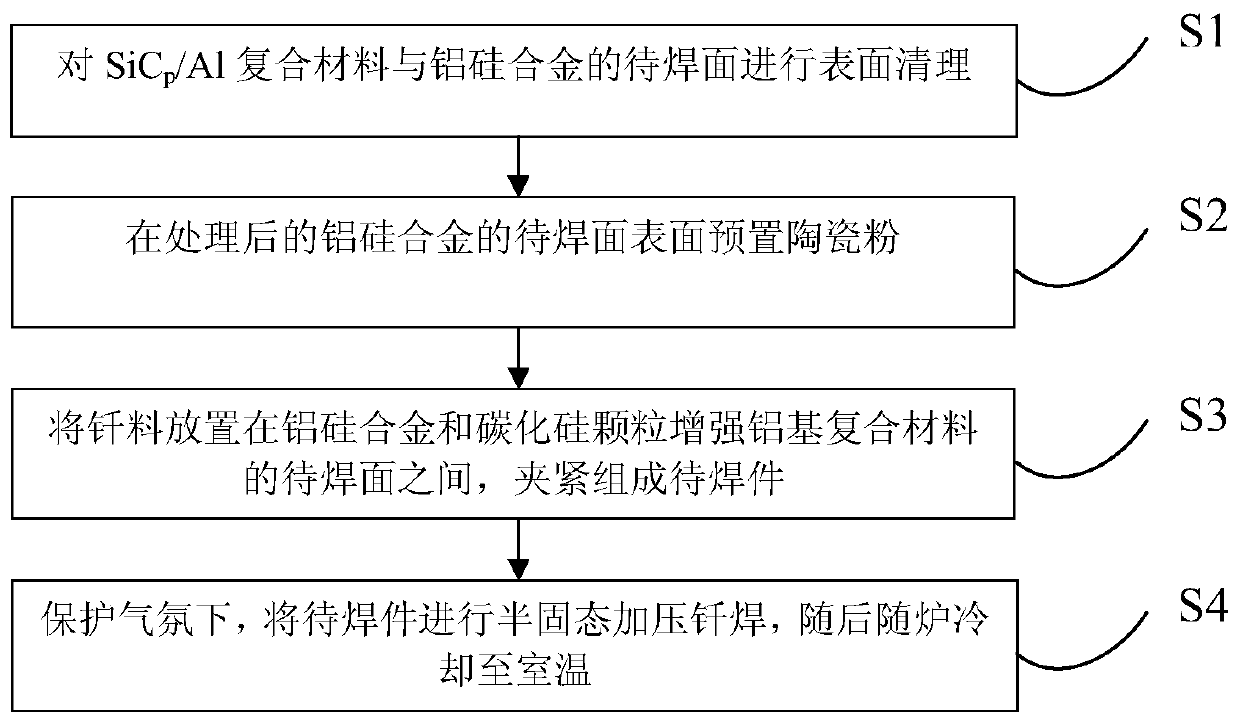

[0057] In this embodiment, the brazing method of high volume fraction silicon carbide particle reinforced aluminum matrix composite material and aluminum-silicon alloy is carried out according to the following steps:

[0058] S1. First, the aluminum-based composite material with a volume fraction of silicon carbide particle reinforcement phase of 63% (referred to as 63% SiC p / Al composite material) and an aluminum-silicon alloy (CE11 alloy for short) with a mass fraction of Si particles of 50% are mechanically polished, then ultrasonically cleaned with absolute ethanol for 10 min, and then taken out and air-dried for later use.

[0059] S2. Weigh 0.005g of SiC powder with a particle size of 1 μm, mix SiC powder and 30ml of absolute ethanol into a beaker with a diameter of 50mm, and obtain a mixed solution of SiC powder and absolute ethanol; Immerse the rod in the mixed solution of SiC powder and absolute ethanol, turn on the ultrasonic vibration, control the ultrasonic vibrat...

Embodiment 2

[0064] In this embodiment, the brazing method of high volume fraction silicon carbide particle reinforced aluminum matrix composite material and aluminum-silicon alloy is carried out according to the following steps:

[0065] S1. First, the aluminum matrix composite material with a volume fraction of SiC particle reinforcement phase of 80% (referred to as 80% SiC p / Al composite material) and an aluminum-silicon alloy (CE19 alloy for short) with a mass fraction of Si particles of 20% are mechanically polished, then ultrasonically cleaned with absolute ethanol for 10 min, and then taken out and air-dried for later use.

[0066] S2. Weigh 0.012g of SiC powder with a particle size of 5 μm, mix SiC powder and 30ml of dehydrated ethanol into a beaker with a diameter of 50mm to obtain a mixed solution of SiC powder and dehydrated ethanol; Immerse the rod in the mixed solution of SiC powder and absolute ethanol, turn on the ultrasonic vibration, control the ultrasonic vibration frequ...

Embodiment 3

[0071] In this embodiment, the brazing method of high volume fraction silicon carbide particle reinforced aluminum matrix composite material and aluminum-silicon alloy is carried out according to the following steps:

[0072] S1. First, the aluminum matrix composite material with a volume fraction of SiC particle reinforcement phase of 50% (referred to as 50% SiC p / Al composite material) and an aluminum-silicon alloy (CE17 alloy for short) with a Si particle mass fraction of 27% are mechanically polished, then ultrasonically cleaned with absolute ethanol for 10 min, and then taken out and air-dried for later use.

[0073] S2. Weigh Al with a particle size of 1 μm 2 o 3 Powder 0.01g, Al 2 o 3 Powder and 30ml of absolute ethanol are mixed into a beaker with a diameter of 50mm to obtain Al 2 o 3 A mixed solution of powder and absolute ethanol; immerse the horn of the ultrasonic transducer in Al 2 o 3 In the mixed solution of powder and absolute ethanol, turn on the ultras...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com