Butt joint positioning device and butt joint positioning method of welding surfaces of concrete mold plates

A technology of concrete formwork and positioning device, applied in the field of concrete formwork machinery, can solve the problems of waste of resources, waste of concrete formwork, short length of concrete formwork, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

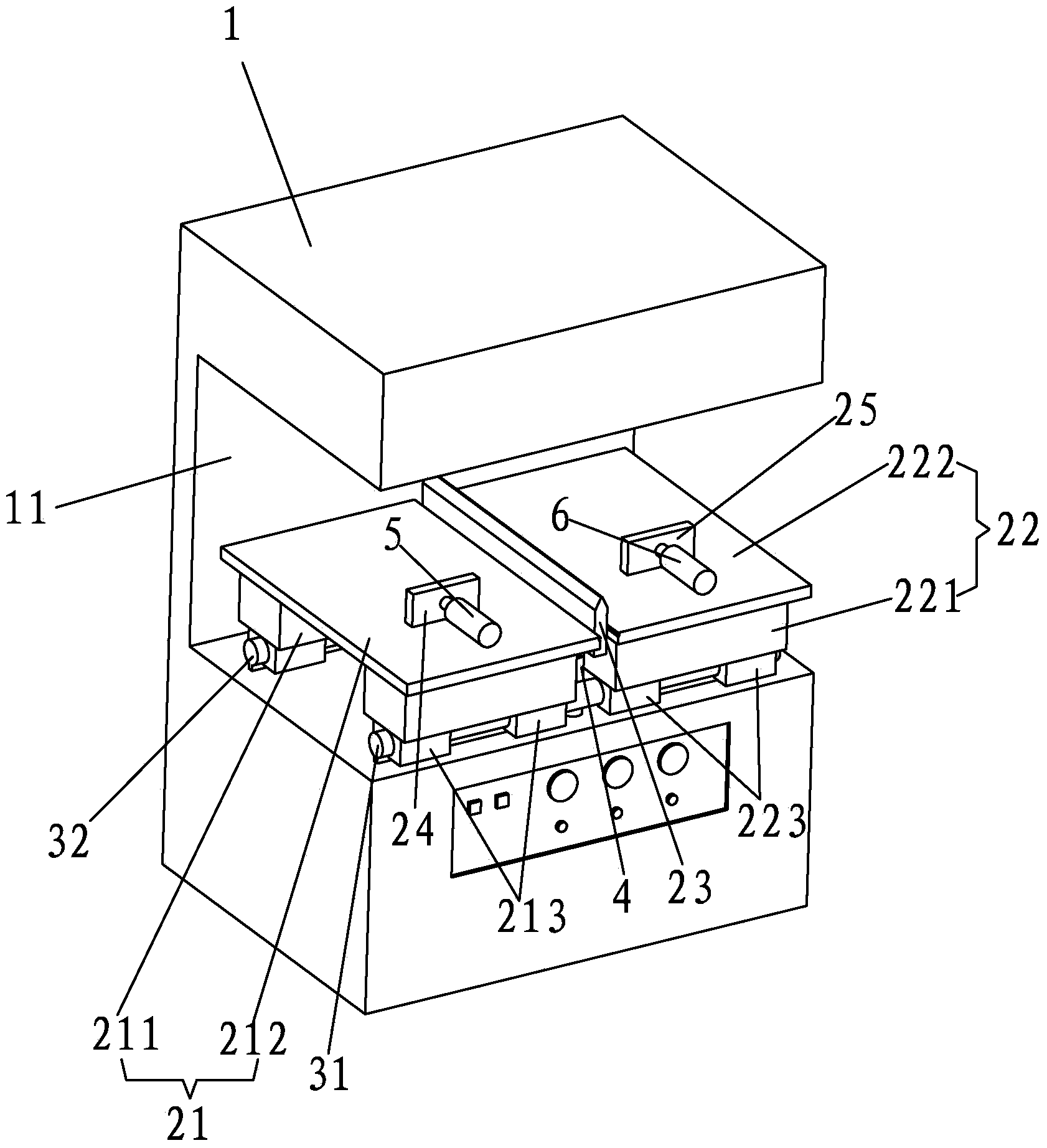

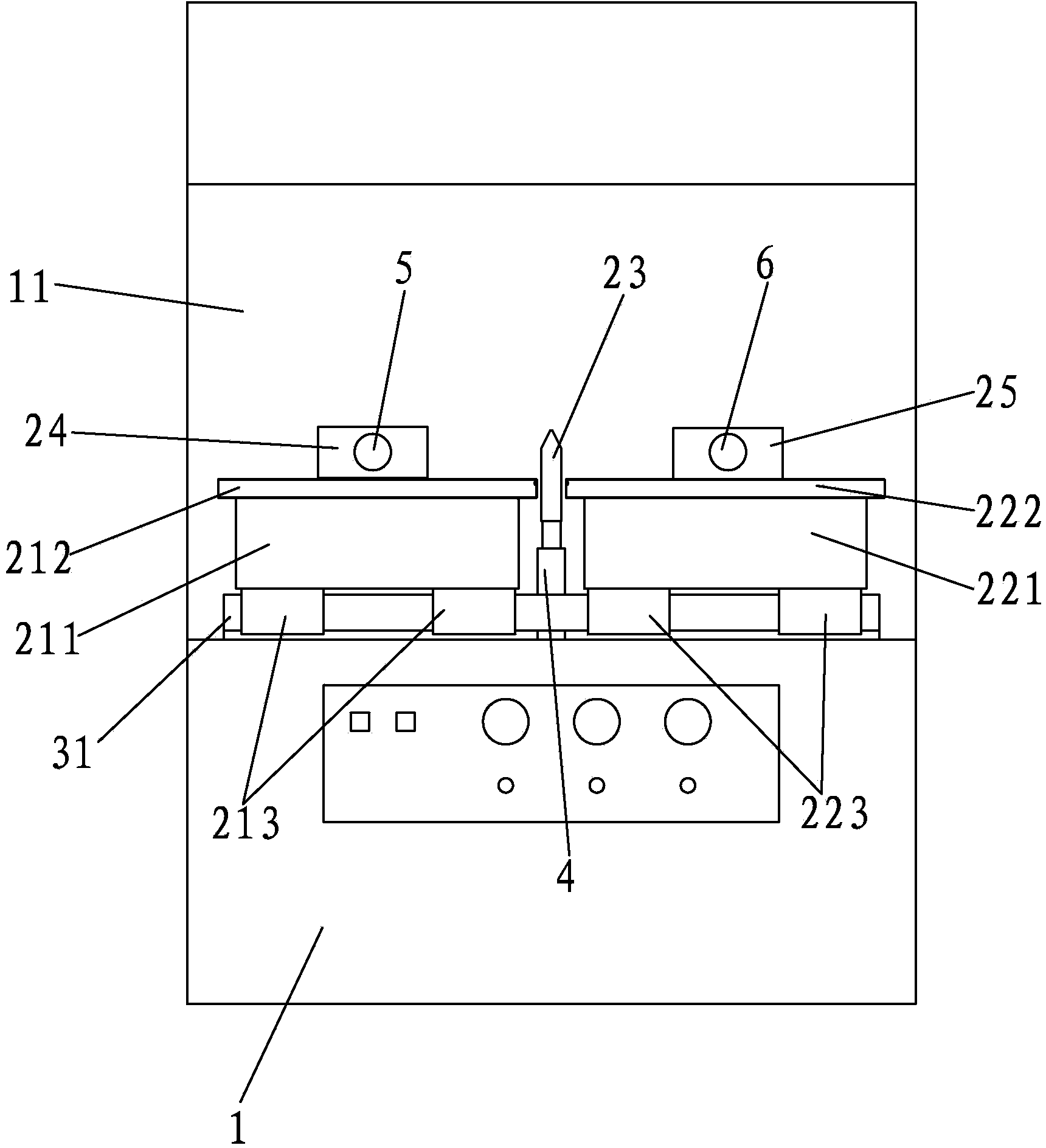

[0031] A butt joint positioning device for the welding surface of concrete formwork, such as figure 1 As shown, including base 1 and positioning device; wherein:

[0032] The base 1 is concavely provided with an installation cavity 11 whose front side, left and right sides are open, and the positioning device is installed in the installation cavity 11 .

[0033] This positioning device comprises left placing platform 21, right placing platform 22, middle positioning plate 23, left front leaning plate 24 and right backing leaning plate 25, and left and right placing platform 21,22 is set up with the mode that can move relatively left and right respectively. In the installation cavity 11, and the left platform 21 and the right platform 22 can be closely matched, the installation cavity 11 is provided with a left...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com