Method for bending automobile oil pipe

A oil pipe and bending technology, which is applied in the field of profile or pipe bending and rod, can solve the problems such as uncontrollable bending angle of oil pipe, and achieve the effect of convenient overall processing, improved stability and convenient management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below by means of specific embodiments:

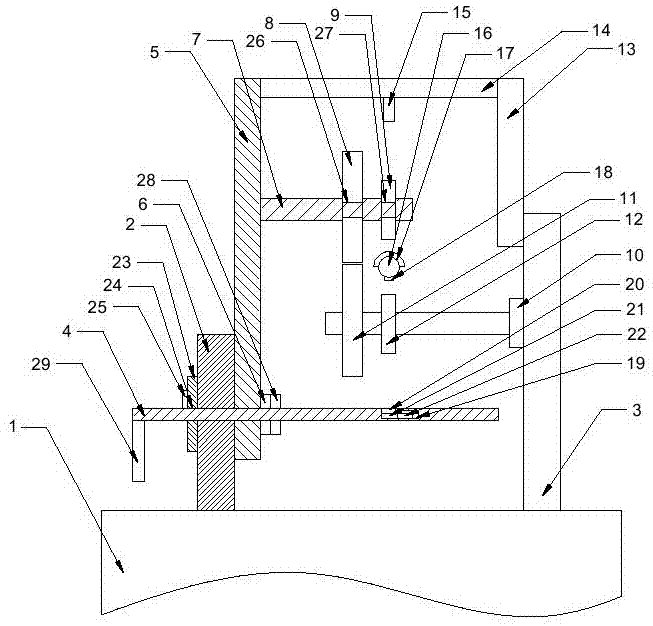

[0023] The reference signs in the accompanying drawings of the specification include: base 1, first support arm 2, second support arm 3, threaded rod 4, first rotating arm 5, adjustment nut 6, support shaft 7, driven gear 8, slave Moving V-shaped wheel 99, motor 10, driving gear 11, active V-shaped wheel 12, second pivoting arm 13, linkage arm 14, infrared emitter 15, detection shaft 16, first infrared receiver 17, first alarm 18 , alarm room 19, infrared receiving hole 20, second infrared receiver 21, second alarm 22, angle plate 23, through hole 24, angle pointer 25, first limit slot 26, second limit slot 27, lock Tighten the nut 28 and turn the handle 29.

[0024] The embodiment is basically as attached figure 1 Shown: the bending device of the automobile oil pipe, including the base 1, on which the first support arm 2 and the second support arm 3 are consolidated se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com