A valve core gland automatic assembly device

An automatic assembly and gland technology, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve problems such as low assembly accuracy, arm soreness, and inaccurate installation of valve core glands.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

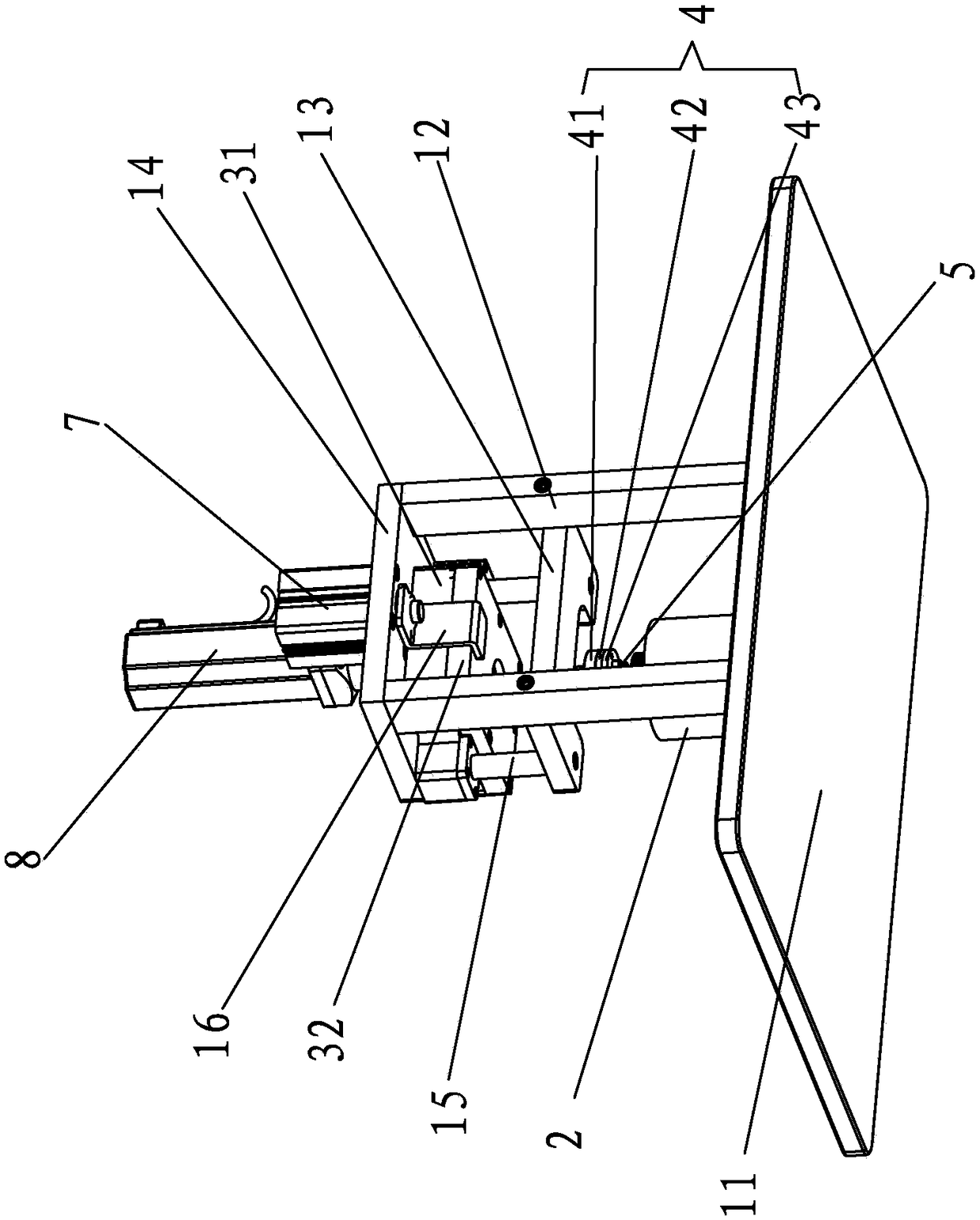

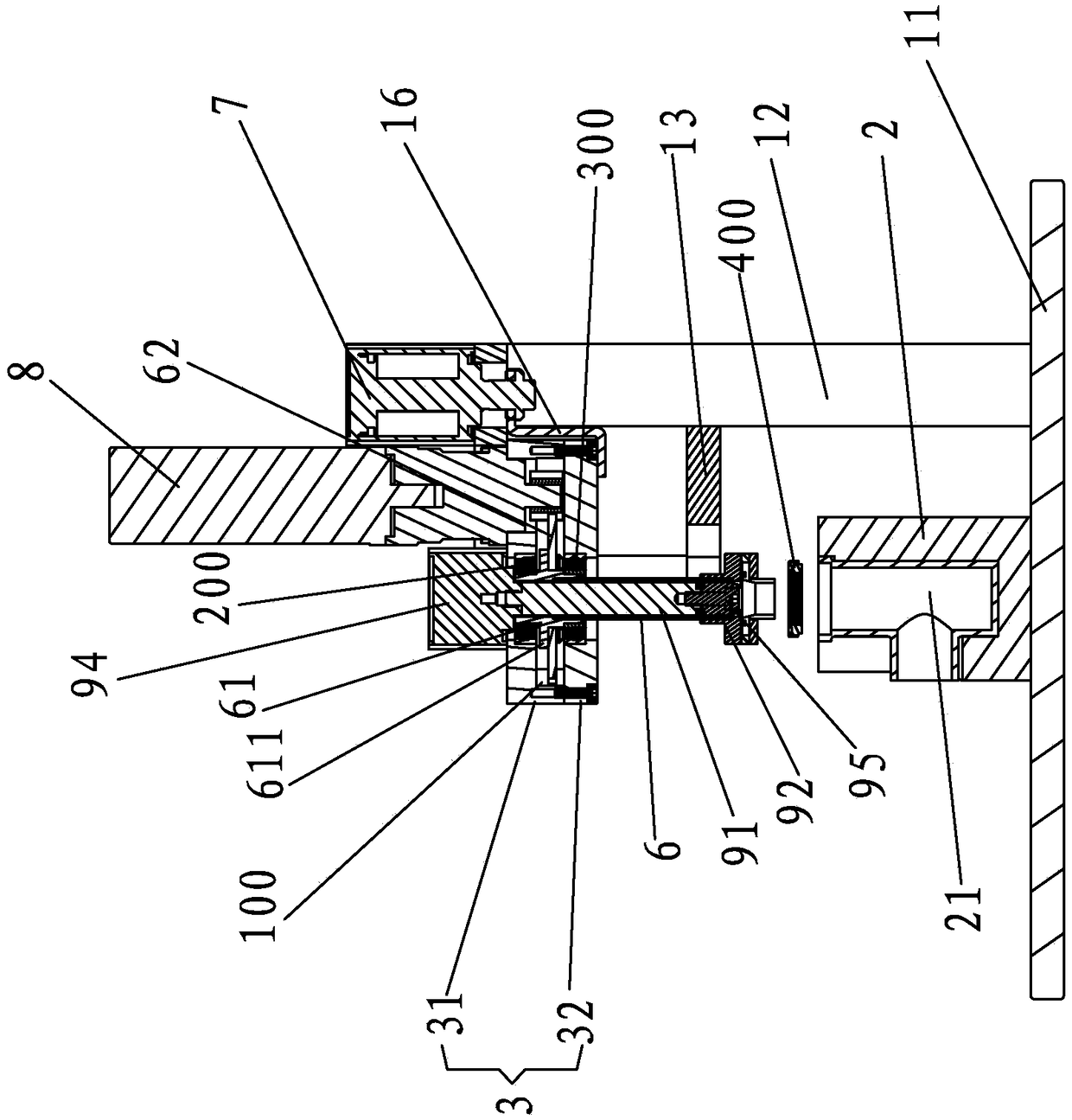

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

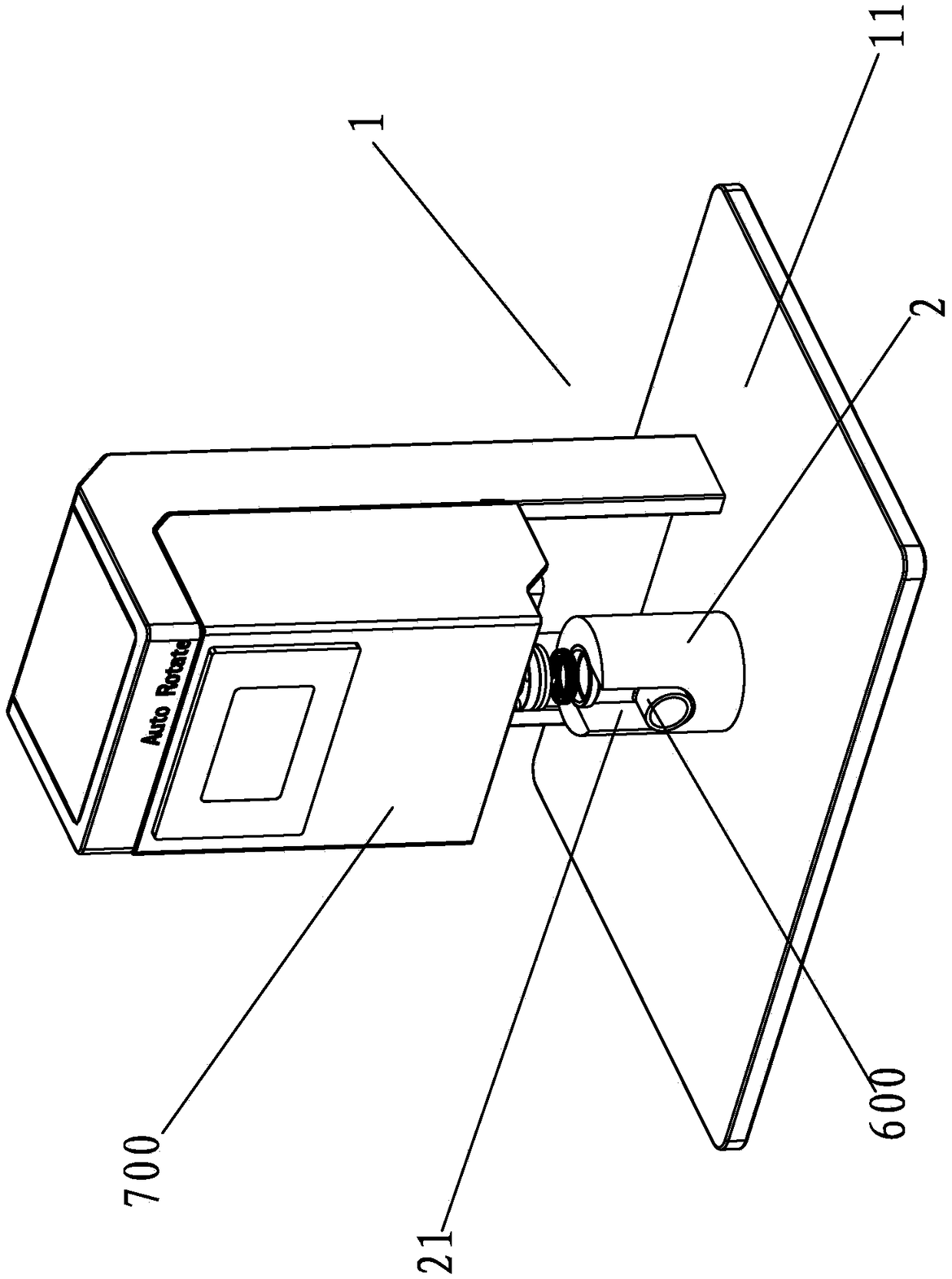

[0027] A kind of valve core gland automatic assembly device of the present invention, such as Figure 1-4 As shown, it includes a working frame 1, a faucet workpiece master mold 2 and a gland workpiece fixture device; wherein,

[0028] The working frame 1 has a working platform 11 and a vertical frame erected on the working platform 11. The faucet workpiece former 2 is in a cylindrical structure. The mold 2 is provided with a faucet placement cavity 21 whose upper end is open, for the faucet housing to be embedded in or removed from the outside; specifically: the top surface of the faucet workpiece master 2 is concavely provided with a cylindrical longitudinal Chamber, the front side wall of the faucet workpiece master 2 is recessed from the front to the radial direction of the faucet workpiece master 2. The cylindrical transverse chamber exte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com