A method of realizing PCB core board positioning by magnetic field

A core board and magnetic field technology, which is applied in the orientation of circuit board tools, multi-layer circuit manufacturing, printed circuits, etc., can solve the problems of high skill requirements of personnel, insufficient punching accuracy of equipment, and difficult control of employees' subjective wishes, so as to solve the problem of hole punching. The impact of bit accuracy and the effect of improving personnel efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

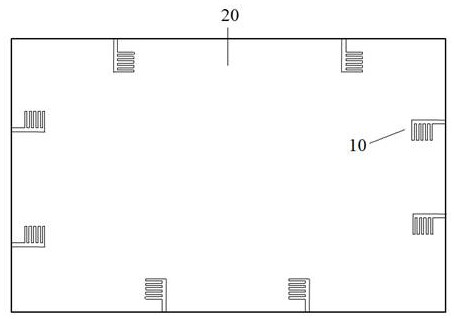

[0037] Example 1: as figure 2 and 3 shown

[0038] Step 1. Board edge positioning graphic design: Provide the board edge pattern requirements to the design department, add the required graphic lines to the inner Gerber data of the non-customer graphics, and each board edge of the core board 20 is provided with 2 inner layer graphics line 10;

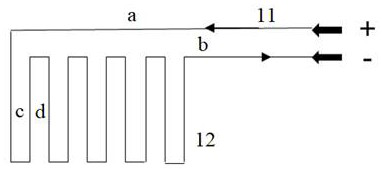

[0039] The inner layer pattern circuit 10 includes two parts, the positive and negative leads 11 and the positioning coil 12. The inner layer pattern circuit 10 is in the shape of a comb, and the positive and negative leads 11 constitute the comb back, the positioning coil 12 and the adjacent The comb groove formed between the comb teeth is formed; wherein, the length a of the comb back is 400-480 mil, the width b of the comb back is 40 mil, the width c of the comb teeth is 40 mil, and the width d of the comb groove is 40 mil.

[0040] Step 2. Inner layer pattern circuit production: including pretreatment, film sticking, exposure, de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com