Bottom sealing strip edge-folding and punching device of bag making machine

A technology of punching device and bag making machine, which is applied in the direction of bag making, packaging, transportation and packaging, etc. It can solve the problem of scratching the back cover tape, etc., and achieve the effect of simple operation and ingenious structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

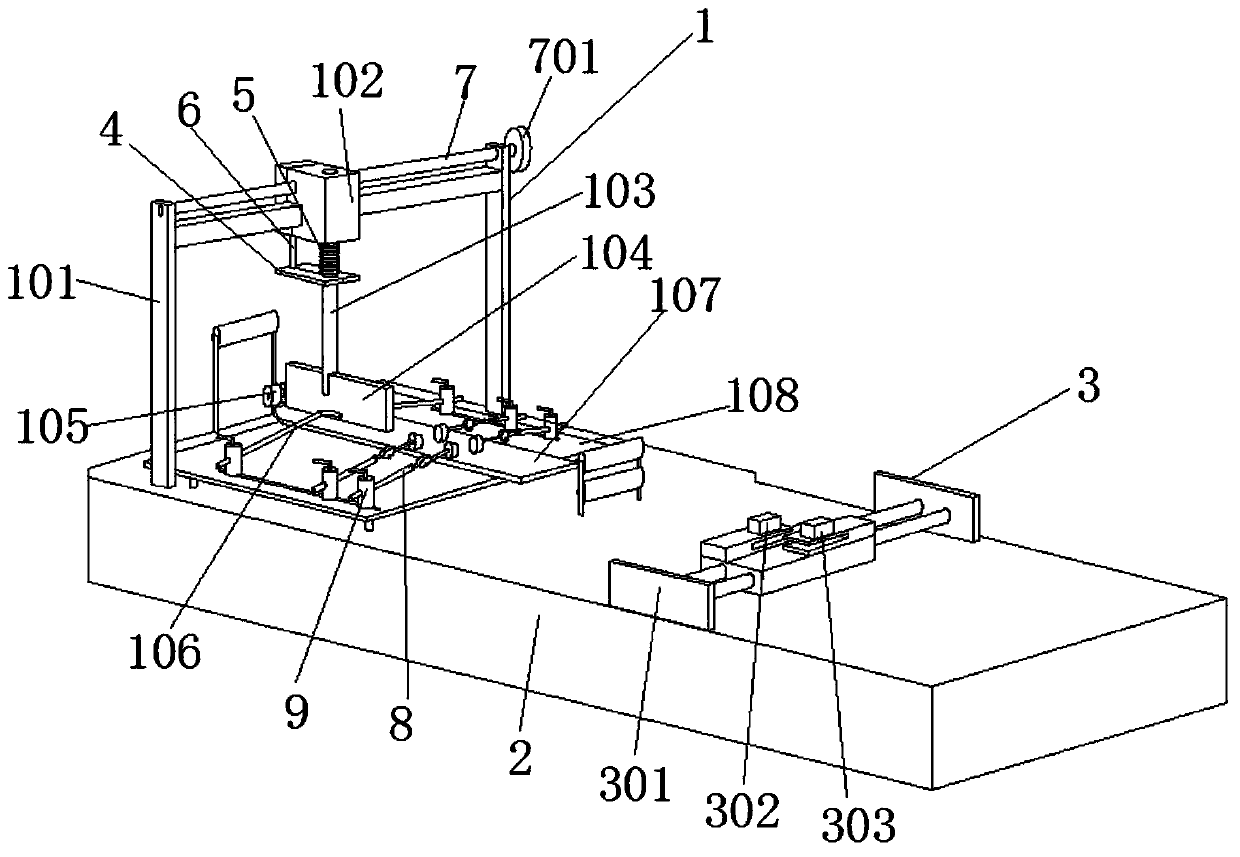

[0026] Such as Figures 1 to 4 As shown, this embodiment discloses a bag-making machine back cover belt hemming and punching device, which is characterized in that it includes a bottom belt hemming assembly 1 and a bottom belt punching assembly 3 .

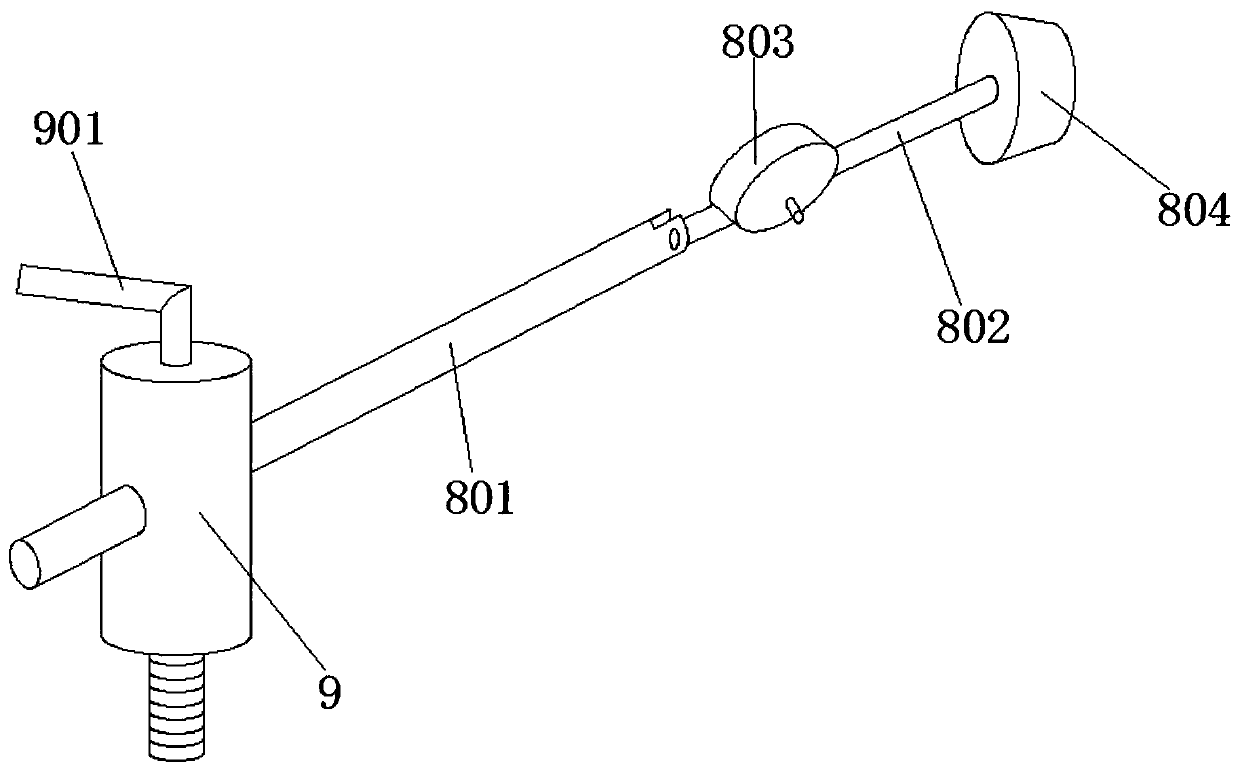

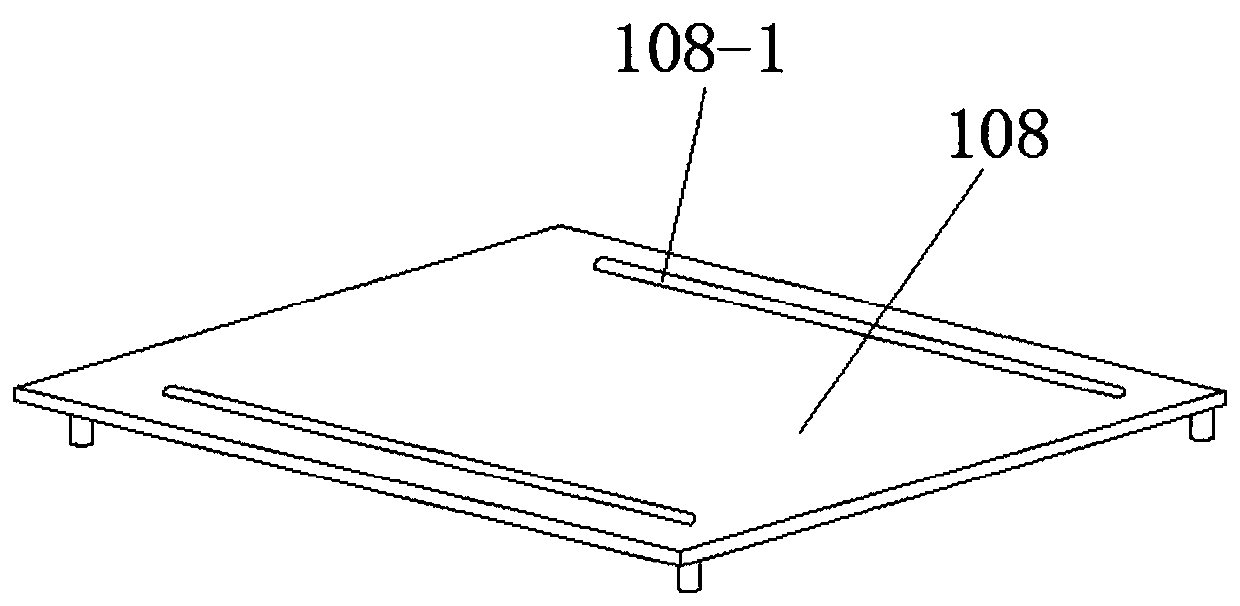

[0027] The bottom belt flanging assembly 1 includes a gantry 101 and a bottom plate 108 arranged on the bag making machine body 2, and a connecting seat 102 is arranged on the beam of the gantry 101, and the connecting seat 102 stands upright with the hemming through the connecting rod 103 below. Plate 104 is connected, and the front end of flanging vertical plate 104 is provided with two bottom belt guide wheels 105, and both sides of flanging vertical plate 104 are all prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com