Automatic adhesive tape device

A tape and automatic technology, applied in the direction of sending objects, thin material handling, transportation and packaging, etc., can solve problems such as unsafe, over-drawn, dirty, etc., to achieve reasonable structural design, accurate output tape, and convenient use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific embodiments of the present invention will be described in further detail below with reference to the accompanying drawings.

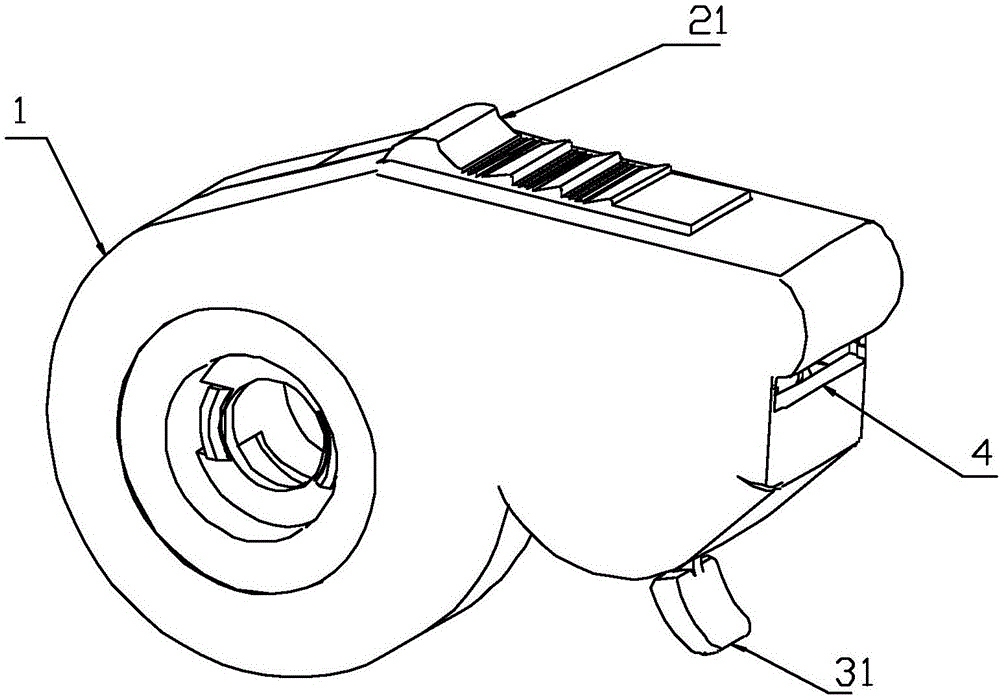

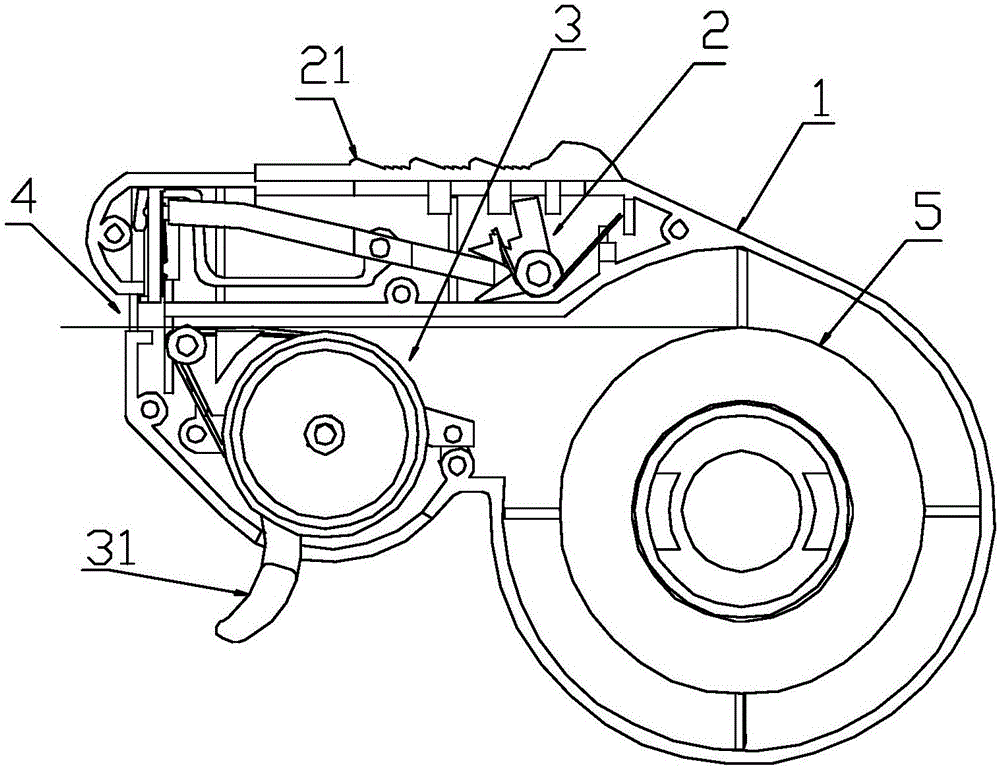

[0032] like figure 1 and figure 2 As shown, an automatic tape dispenser includes a detachable casing 1, one side of the casing 1 is provided with an adhesive tape outlet 4, and the casing 1 has a cavity for installing the adhesive tape 5, and the cavity is communicated with the adhesive tape outlet 4 , the adhesive tape 5 is rotatably installed in the cavity, and is led out from the adhesive tape outlet 4 .

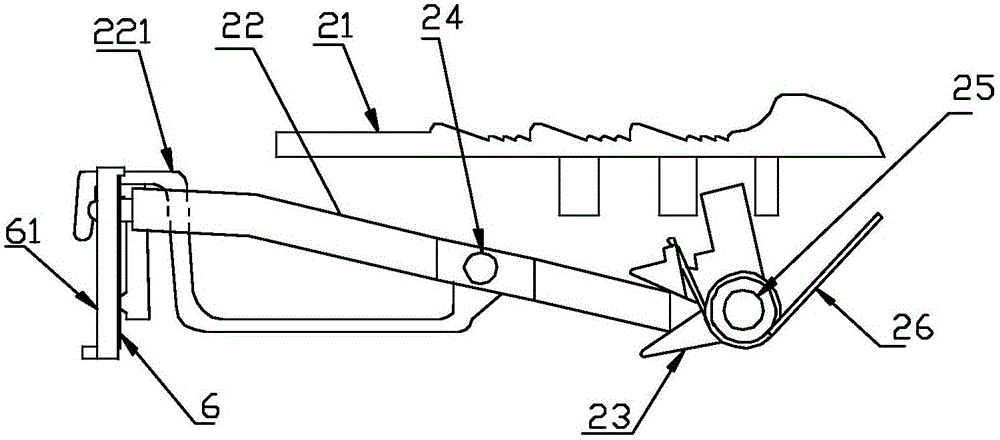

[0033] The automatic tape dispenser also includes a tape cutting mechanism and a tape output mechanism 3 . The tape cutting mechanism includes a cutter 6 arranged in the housing 1 and a cutter drive mechanism 2 for driving the cutter 6 to move to cut the tape 5 . The cutter drive mechanism 2 can be powered by human hands, so that the cutter 6 cuts off the tape at the tape outlet 4; the tape output mechanism 3 is arranged at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com