Ball separating device of bearing ball separating holder assembly machine

A cage and assembly machine technology, applied in the direction of bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of bearing steel ball and channel damage, ball needle bending, fracture, etc., to extend service life, not easy to break Or bending deformation, the effect of high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

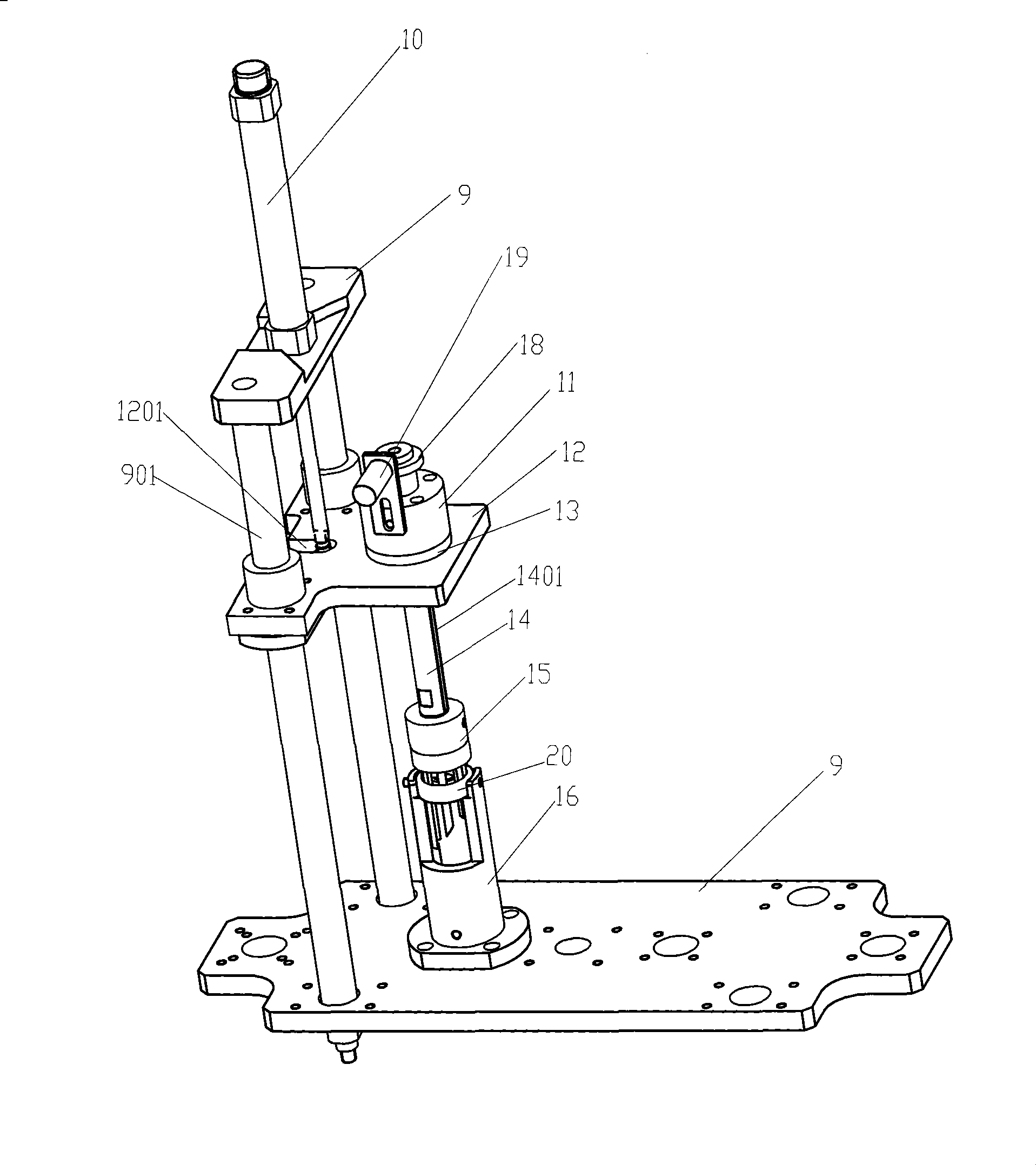

[0019] The specific embodiments of the present invention will be described in further detail below with reference to the accompanying drawings.

[0020] Such as image 3 As shown in 4, the present invention includes a frame 9 and an electronic control system (not shown in the figure). The upper part of the frame 9 is equipped with an air cylinder 10, and the frame 9 is equipped with two guide shafts 901, and a sliding device of the pallet 12 On the guide shaft 901, the piston rod of the cylinder 10 passes through the hole 1201 of the support plate 12, and the lifting head 17 of the support plate 12 is installed at the front end of the piston rod. When the piston rod of the cylinder 10 retracts, the front end of the piston rod The lifting head 17 pulls the pallet 12 to move upward along the guide shaft 901. When the piston rod of the cylinder 10 extends, the pallet 12 loses its downward restriction and depends on the weight of the pallet 12 and the mandrel mounted on it. Moving dow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com