Double-roller hoisting device suitable for multi-roller rolling mill

A technology of lifting device and rolling mill, which is applied in the direction of transportation and packaging, load hanging components, etc., can solve the problems of manpower and time consumption, low production efficiency, etc., and achieve the effect of easy operation, stable work, safe and efficient lifting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited in any way, and any changes or improvements based on the teaching of the present invention fall within the scope of protection of the present invention.

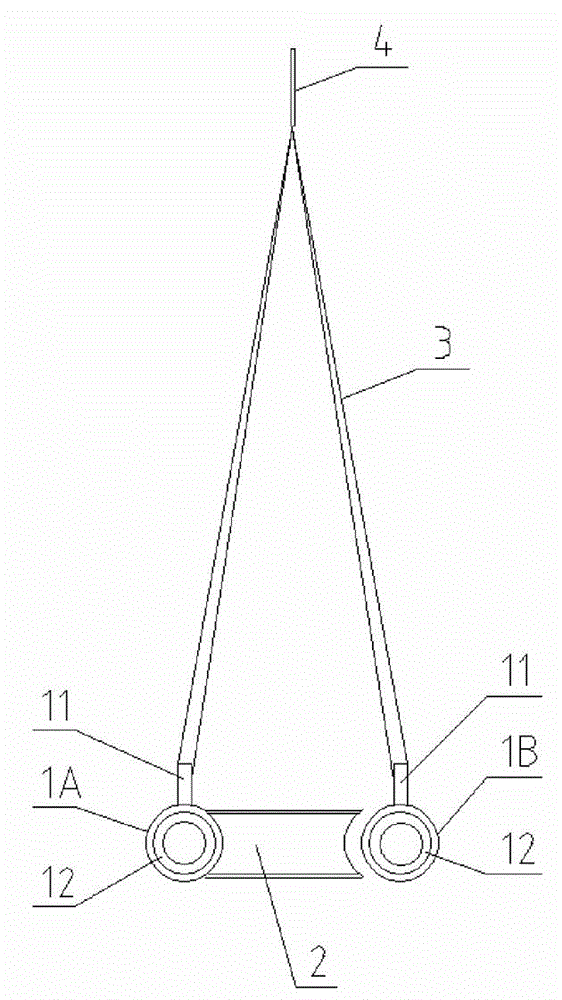

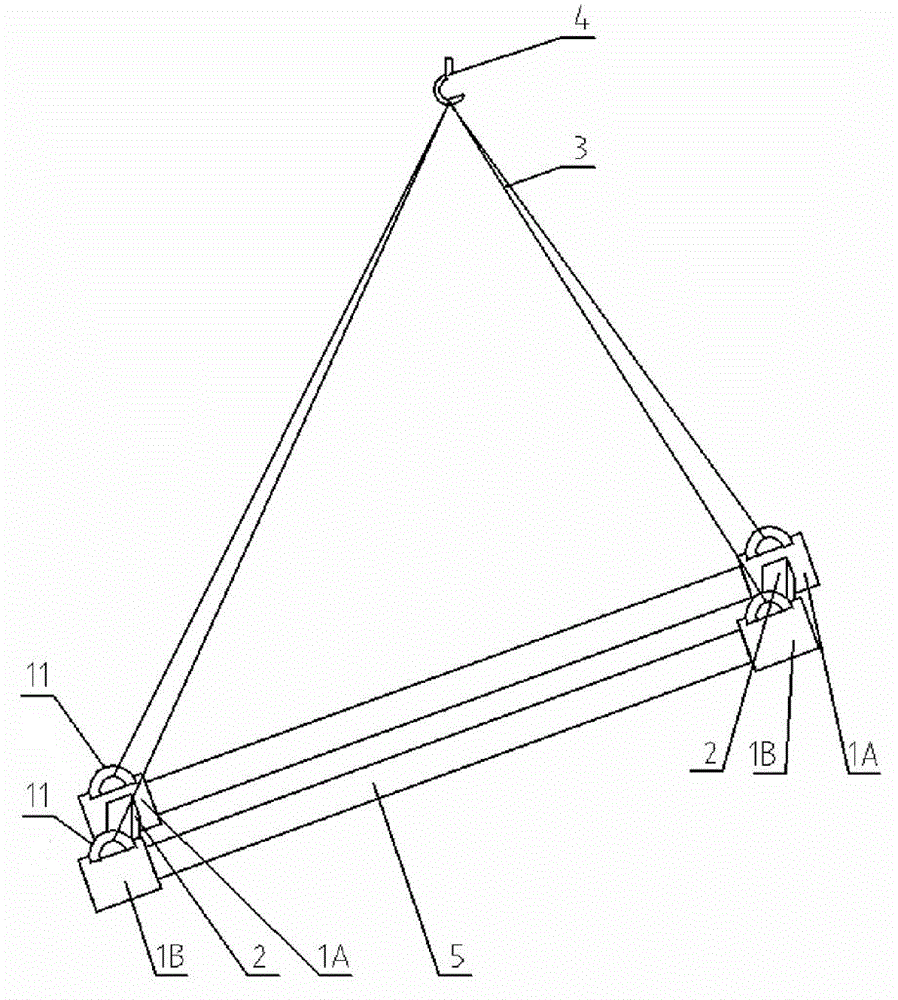

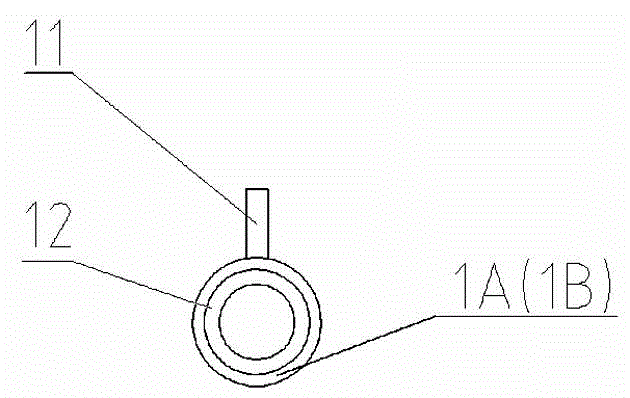

[0015] Such as Figure 1~5 As shown, the present invention includes suspension buckles 1A-1B, spacer rod 2, and suspension rope 3, and each of the suspension buckles 1A and 1B constitutes a group of movable buckles, and the two groups of movable buckles form a pair of slings; The inner diameter of the cylinder 12 of the lifting buckle 1A and the lifting buckle 1B is 10 to 20% larger than the diameter of the roll neck to be hoisted; the lifting buckle 1A and the lifting buckle 1B are connected to the roll necks at both ends of the lifting roll; the spacer rod 2 It is fixedly connected with the suspension buckle 1A; the two ends of the suspension rope 3 are respectively fixedly co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com