Safe combined type assembling and disassembling tool for intermediate transition car coupler

A technology for transitional couplers and loading and unloading tools, which is applied in transportation and packaging, railway car body parts, railway vehicle coupling accessories, etc., and can solve the problems of heavy weight of intermediate transitional couplers, shifting and falling of the center of gravity of sliders, and personal safety of workers. Threats and other issues, to achieve the effect of reducing labor intensity, convenient placement and movement, and reducing personal safety risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing:

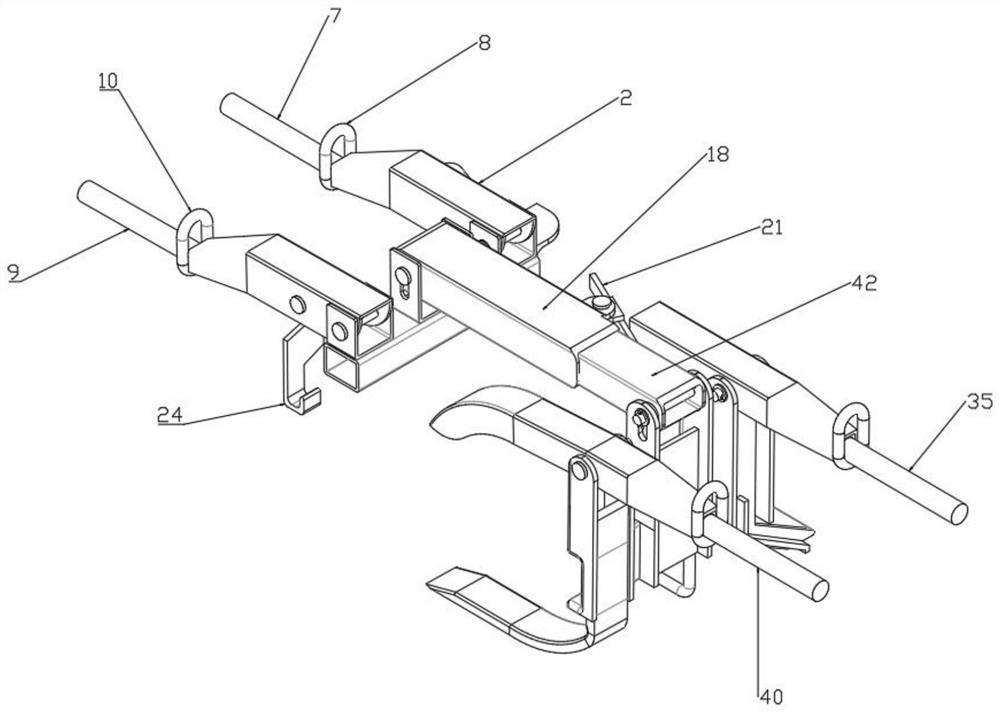

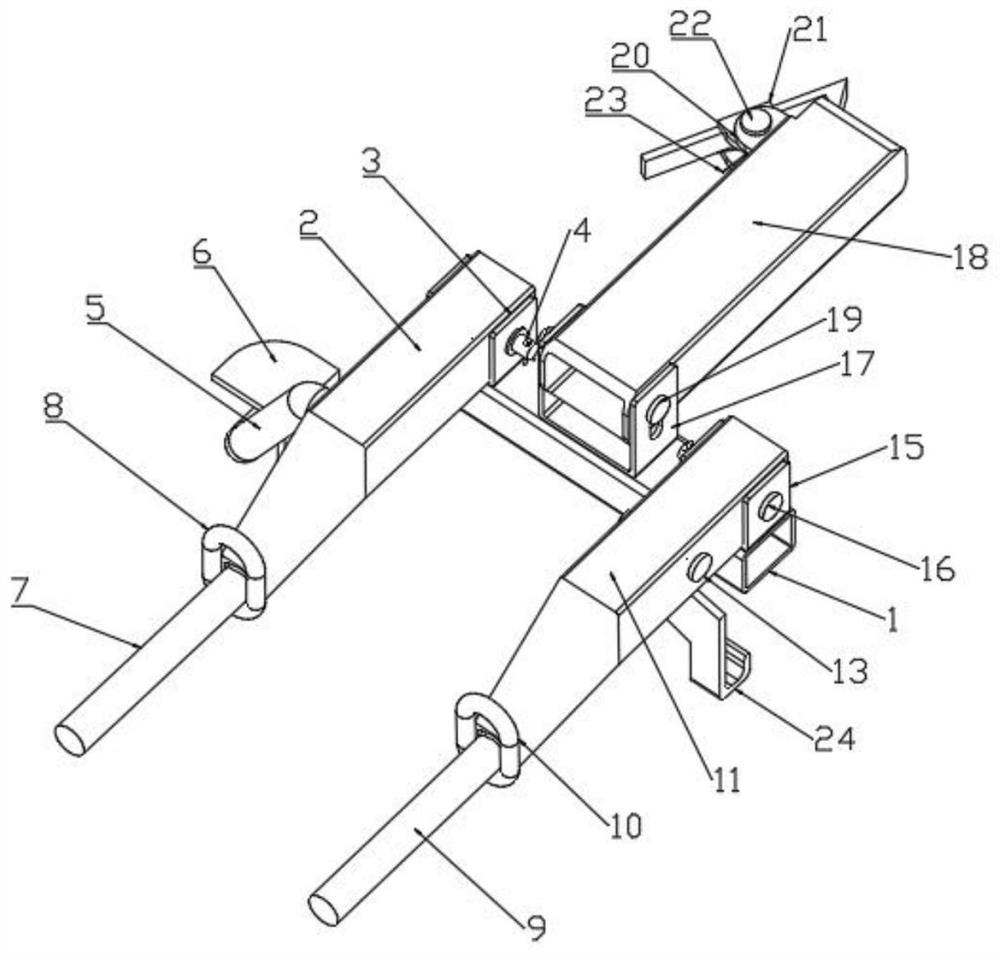

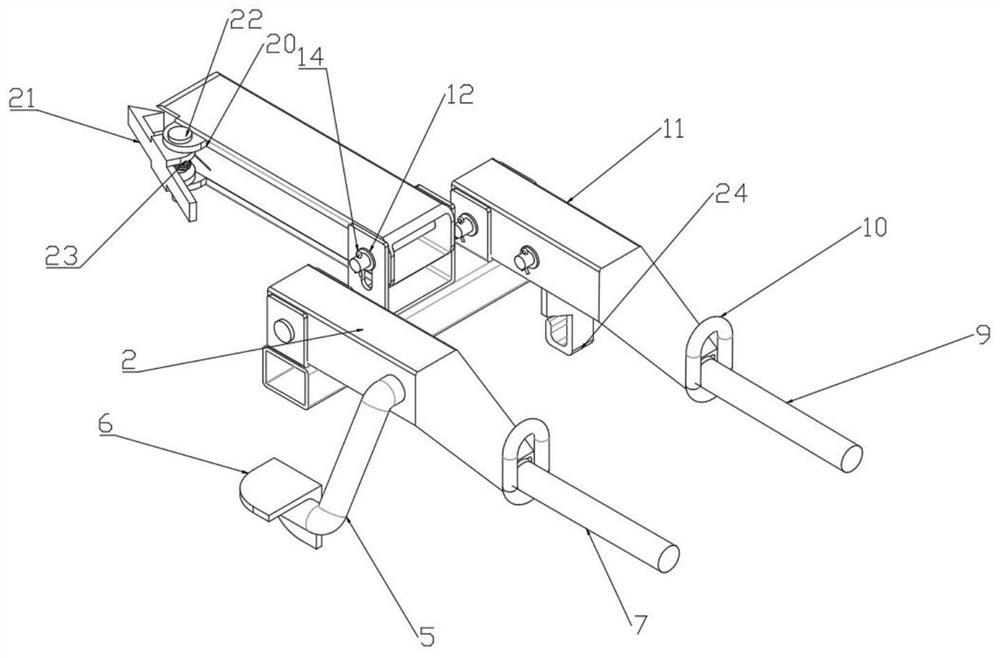

[0018] Such as Figure 1-6 Shown: Left fixture: The left fixture installation frame 1 is the basic accessory for installing all the accessories and accessories of the left fixture; the frame contains the mounting seat 3 of the left rear support lever, the left front support lever mounting seat 15, and the installation of the left upper limit pull rod Seat 17, all have round pin installation hole on each mounting seat, so that each accessory is installed. The left upper limit pull rod mounting seat 15 has an oval slotted hole. So that the left upper limit pull rod 18 can move up and down, in order to cooperate with the right upper limit pull rod 42 to carry out spacing and positioning, the left upper limit pull rod 15 is welded with the left upper limit pull rod lock mounting seat 20, the left upper limit pull rod lock 21. Install the round pin 22 and the self-locking spri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com