Universal type plate placing machine

A general-purpose technology for board placement machine, applied in conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of inability to achieve 180° turning over of the PCB board, and unavoidable scratches on the surface of the PCB board, so as to reduce scratches. The chance of injury, the effect of improving stability, and increasing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

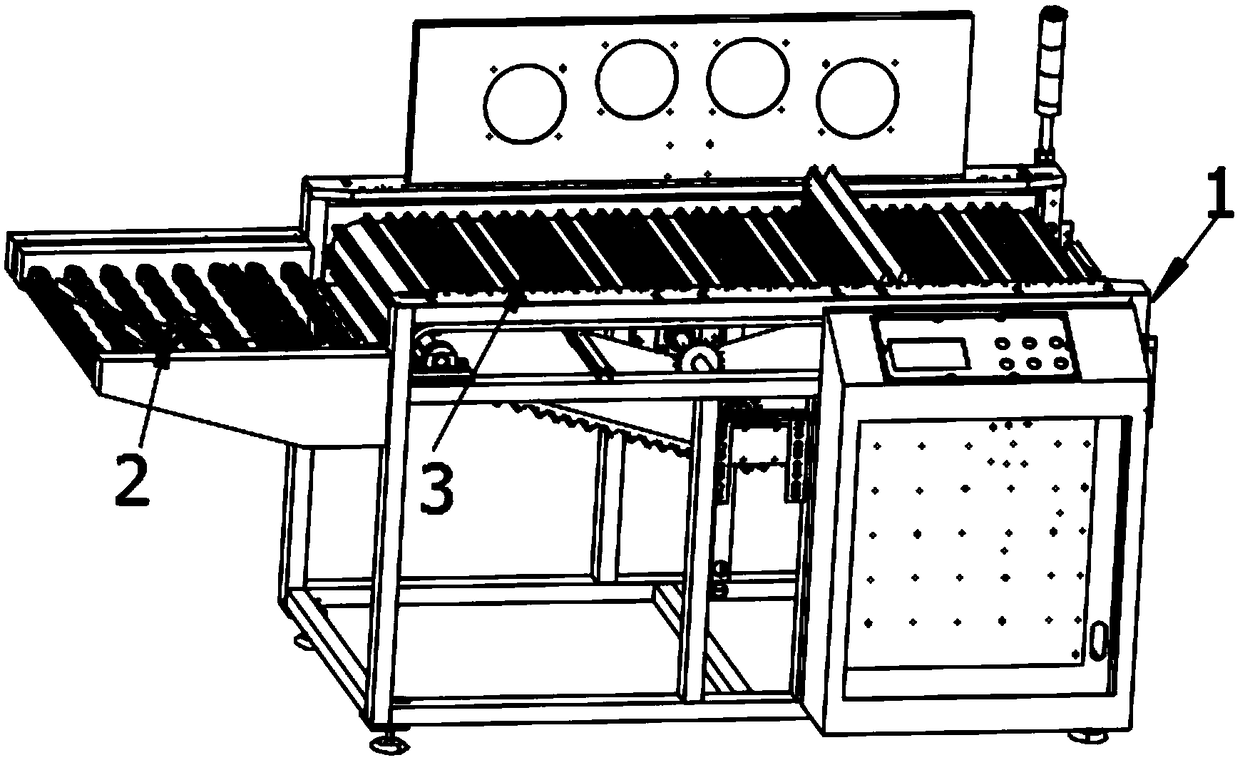

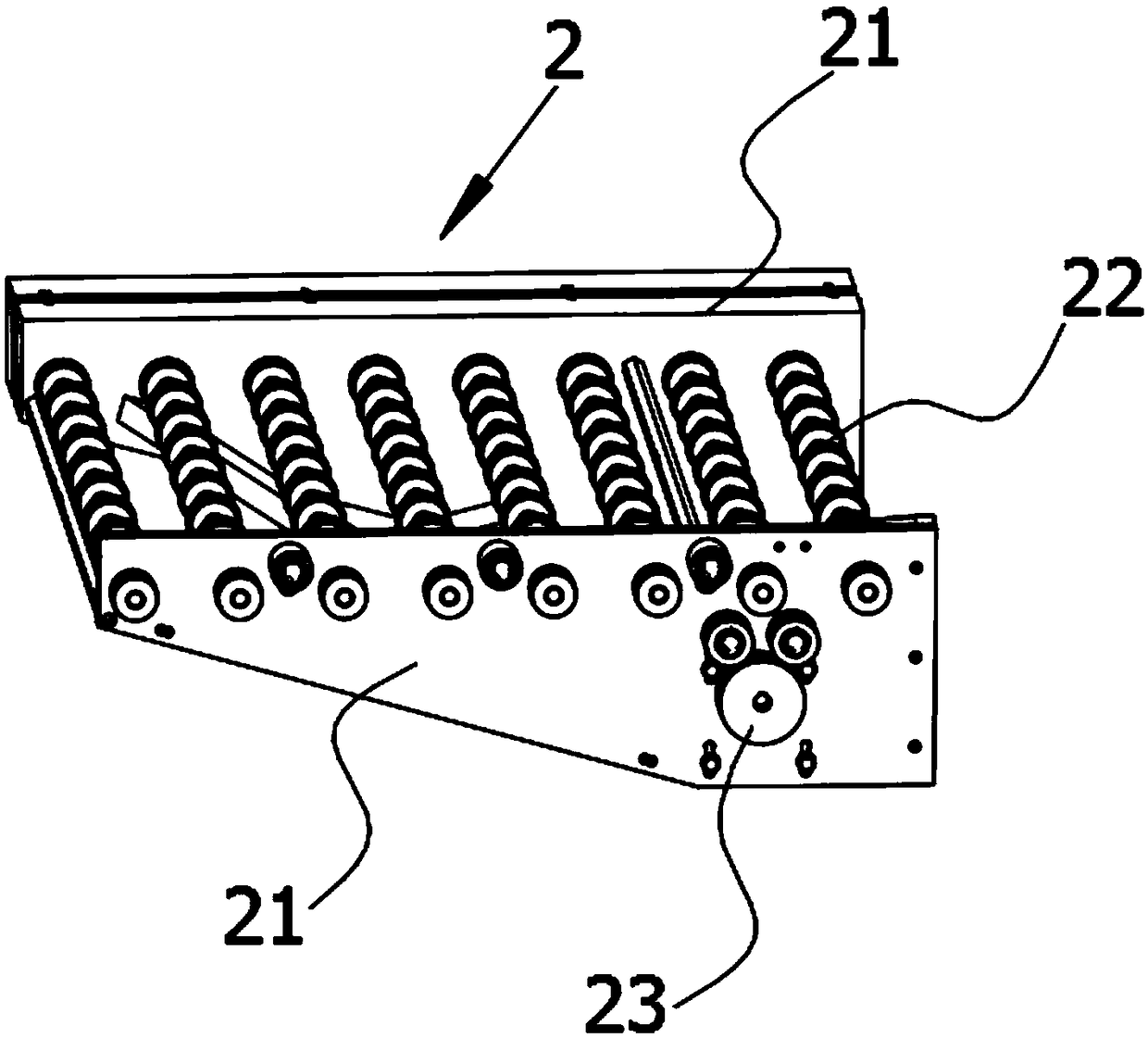

[0035] Embodiment: a kind of universal board machine, as Figure 1-Figure 8 As shown, it includes a frame 1 and a transmission mechanism 2 fixed on the frame and a delivery turning mechanism 3, and the transmission mechanism is located at the downstream of the delivery turning mechanism;

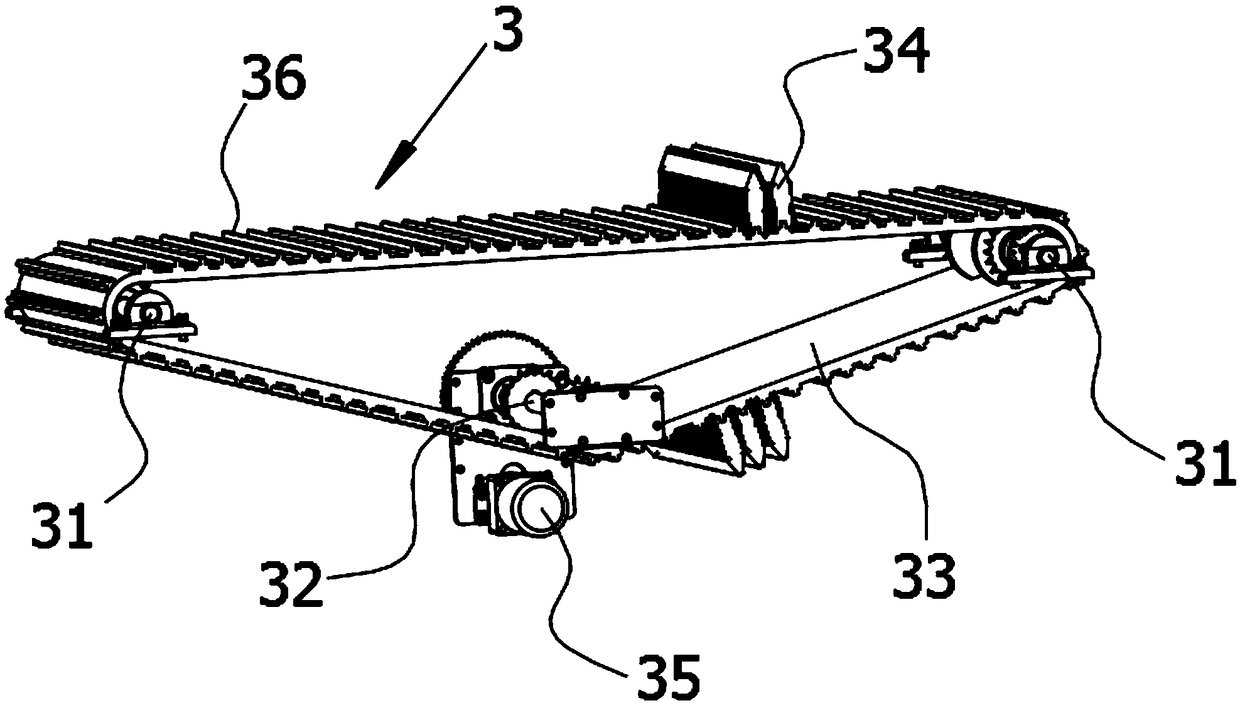

[0036] The conveying turning mechanism includes two driven rollers 31 and a driving roller 32 fixed on the frame, a conveying belt 33 connected to the driven roller and the driving roller, and an overturning splint 34 detachably connected to the conveying belt. Between the two driven rollers, a first motor 35 is connected to one end of the driving roller;

[0037] The outer peripheral surface of the conveyor belt has a plurality of clamping blocks 36, the length direction of the clamping blocks is parallel to the width direction of the conveyor belt, and the lower end of the turning splint has a clamping groove 341 which is clamped with the clamping blocks , the left and right side walls of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com