Vacuum cleaner front cover switching-on two-position spacing structure

A technology of vacuum cleaner and limit structure, applied in the direction of vacuum cleaner, cleaning equipment, household appliances, etc., can solve the problems of reduced product versatility, scratched front cover, unusable dust box, etc., to improve versatility and increase competition force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

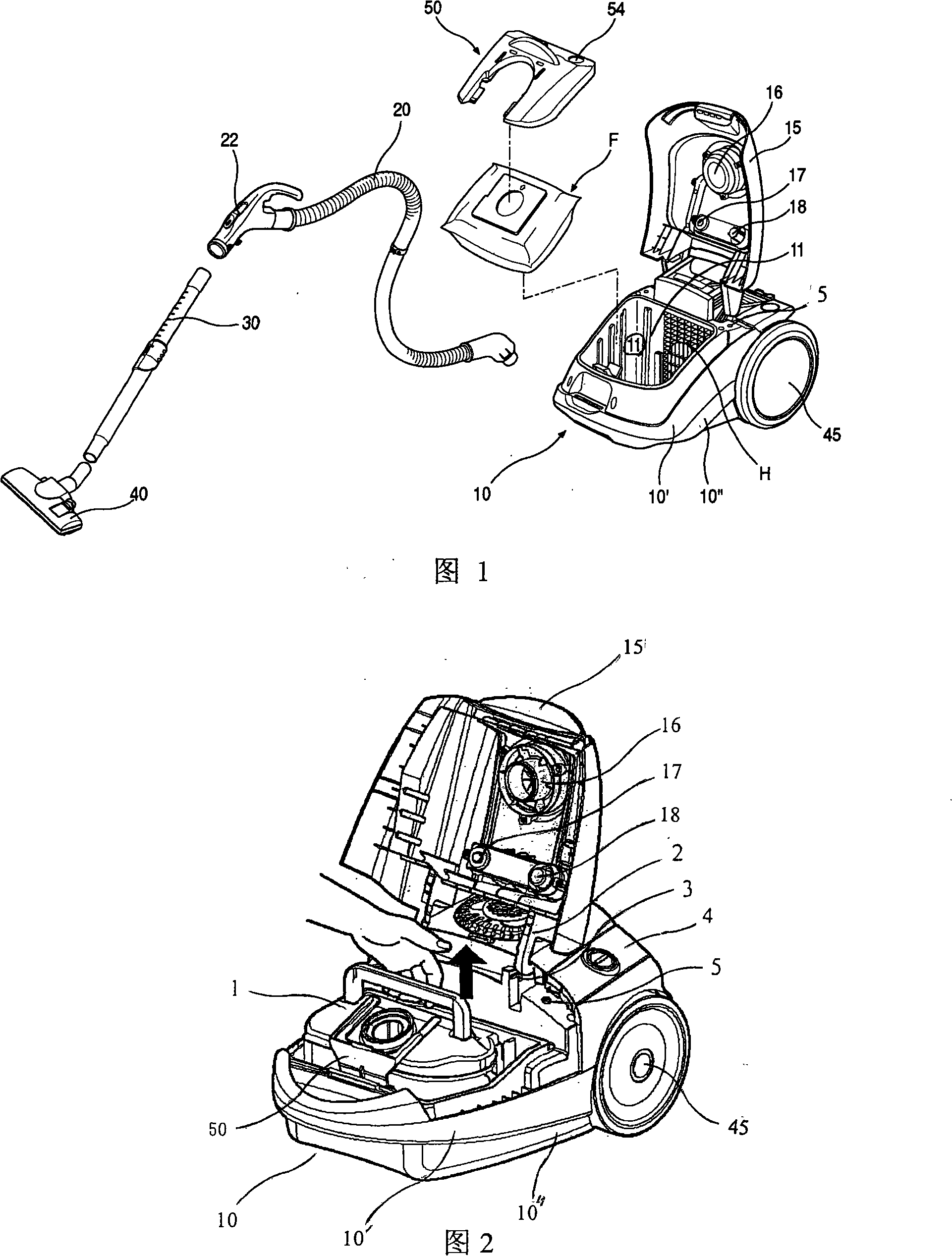

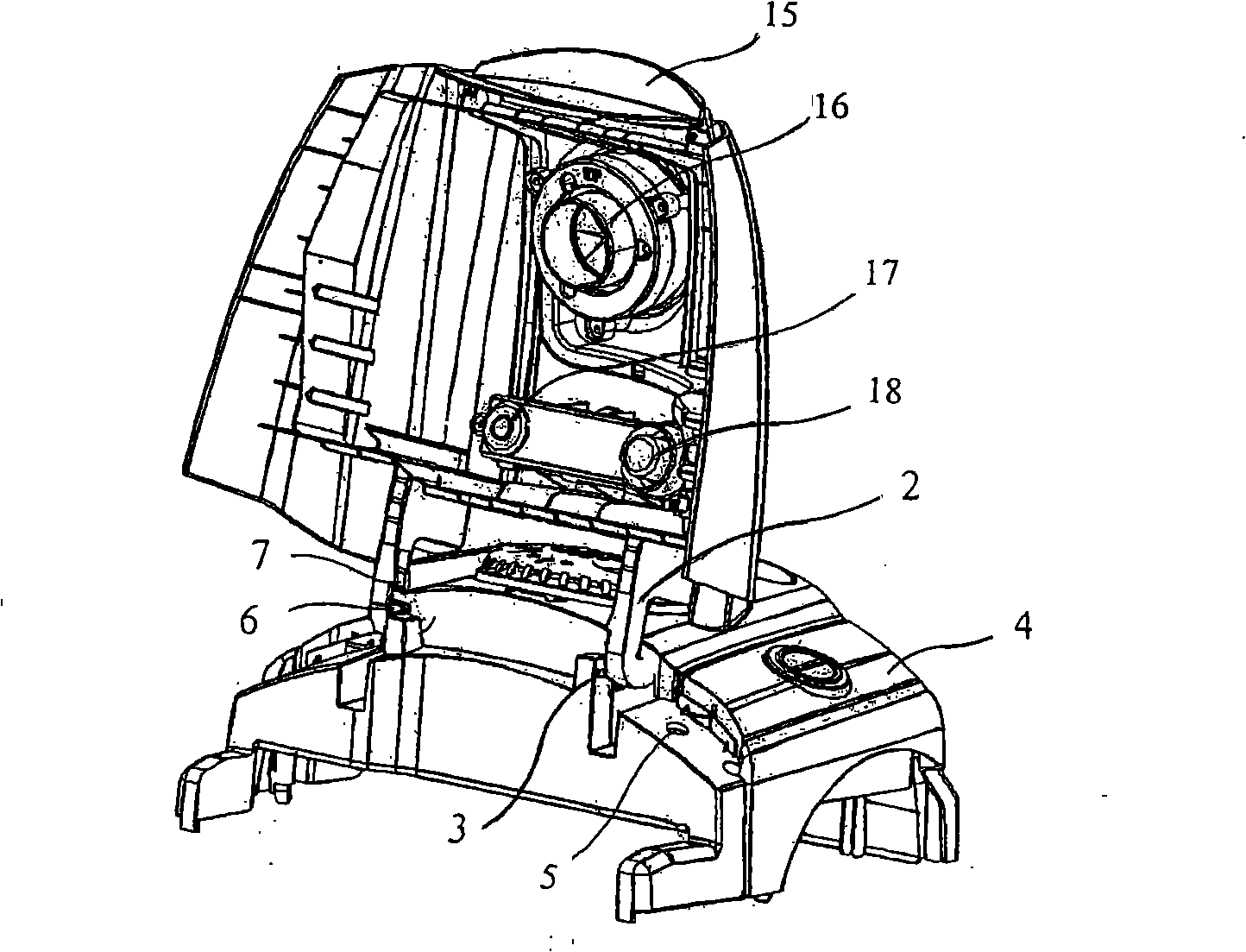

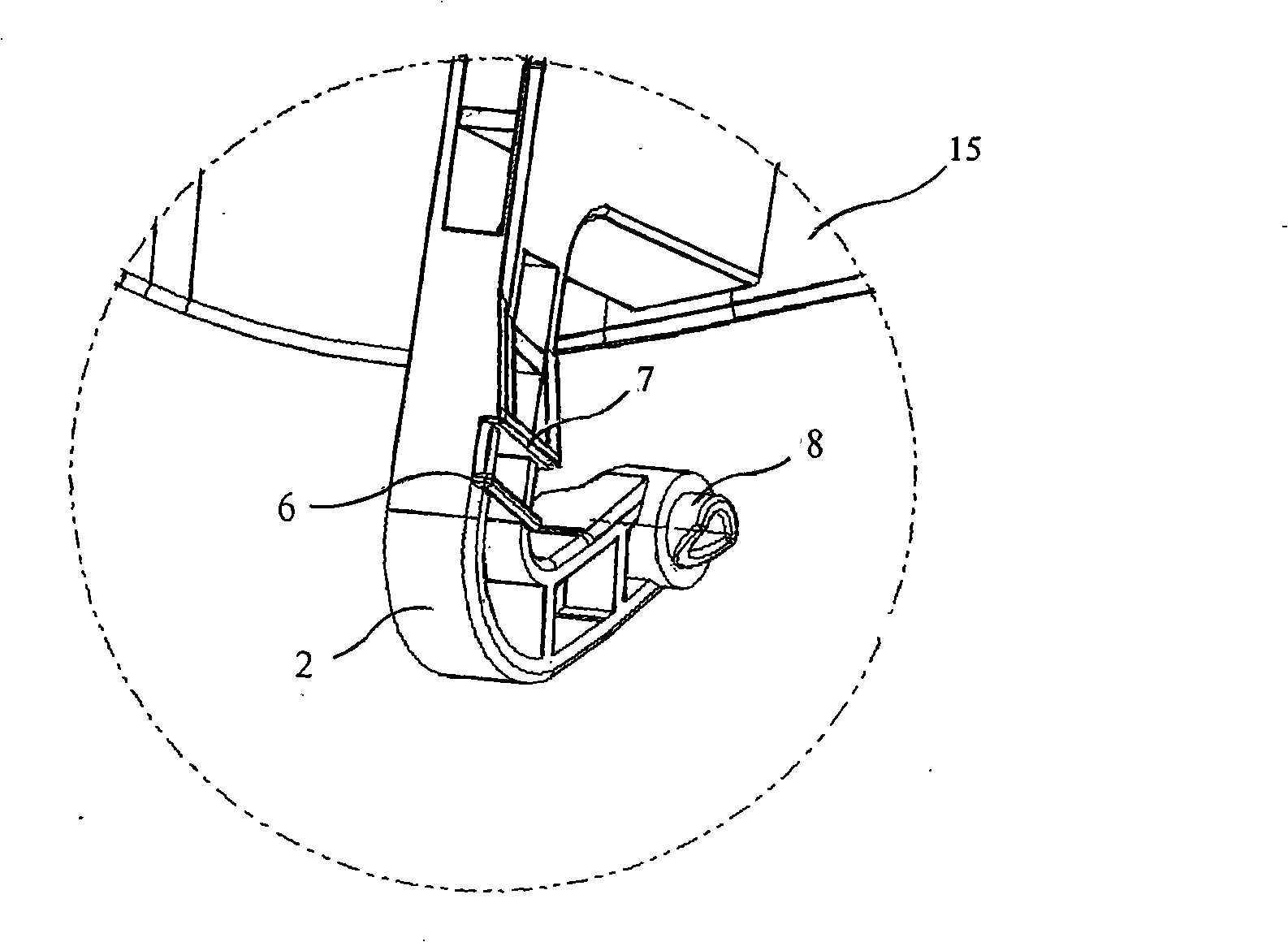

[0044] In order to further illustrate the content, technical characteristics and effects of the present invention, the following examples are given and described below in conjunction with the accompanying drawings: As shown in Figures 1-6, the technical solution of the present invention includes: a main body 10 with a suction fan inside; The casters 45 arranged on both sides of the main body; the suction nozzle 40 communicated with the inside of the main body through the connecting hose 20 and the telescopic tube 30; the upper and lower casings 10', 10 ", the front cover 15, and the rear cover 4 forming the appearance of the main body; The dust collecting part 11, which is arranged in the front of the housing and recessed to the inside of the main body; the dust bag fixing clip 50 snapped on the front of the dust collecting part; the dust collecting bag F and the dust collecting box 1 which can be installed in the dust collecting part, The feature is: in order to facilitate the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com