Submerged-arc welding high-moisture oxidation-resistant lead-free solder and preparation method thereof

A lead-free solder and submerged arc welding technology, which is applied in metal processing equipment, welding equipment, welding/cutting media/materials, etc., can solve the problems of solder stability, electromagnetic induction, etc., and achieve good wettability, The effect of good toughness and creep properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

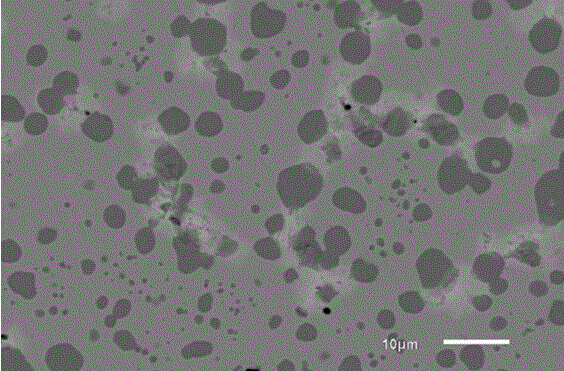

[0040] A high-wetting oxidation-resistant lead-free solder is composed of the following raw materials in weight percent:

[0041] Cu: 0.5%, Ni 3 V: 0.2%, nano ZrO 2 Particles: 0.6%, the balance being Sn.

[0042] According to the above weight percentage, Cu powder, Ni 3 V particles, nano ZrO 2 Particles, and Sn block, after mixing evenly, take a total mass of 2Kg, and place it in Al 2 o 3 crucible, and then sent it to a 500 ° C resistance furnace for melting. After it is completely melted, keep it warm for 150 minutes, fully stir it and take it out of the furnace, pour it into a welding rod mold, and obtain a lead-free solder bar after cooling.

Embodiment 2

[0044] A high-wetting oxidation-resistant lead-free solder is composed of the following raw materials in weight percent:

[0045] Cu: 0.7%, Ni 2 V: 0.3%, nano ZrO 2 Particles: 0.5%, the balance being Sn.

[0046] The preparation method of the lead-free solder strip in this example is the same as the preparation method of the lead-free solder strip in Example 1, the only difference is that the weight percentage of each component in the lead-free solder strip is weighed according to this example.

Embodiment 3

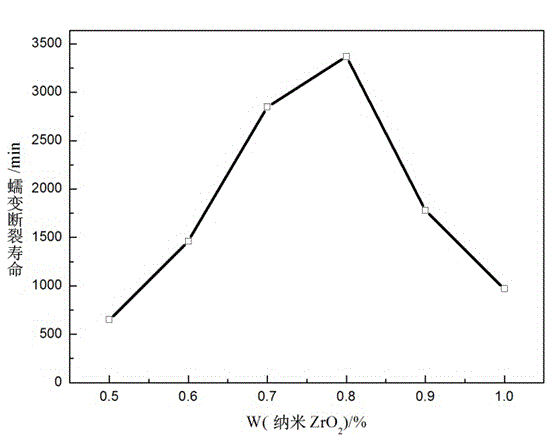

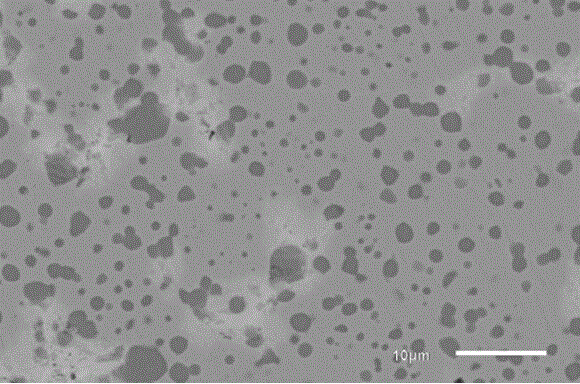

[0048] A high-wetting oxidation-resistant lead-free solder is composed of the following raw materials in weight percent:

[0049] Cu: 0.5%, NiV 3 : 0.1%, nano ZrO 2 Particles: 0.8%, the balance being Sn.

[0050]The preparation method of the lead-free solder strip in this example is the same as the preparation method of the lead-free solder strip in Example 1, the only difference is that the weight percentage of each component in the lead-free solder strip is weighed according to this example.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com