Push rod device for electromagnet

A push rod device, electromagnet technology, applied in the direction of electromagnets, etc., can solve the problems of complex production process and residual magnetism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

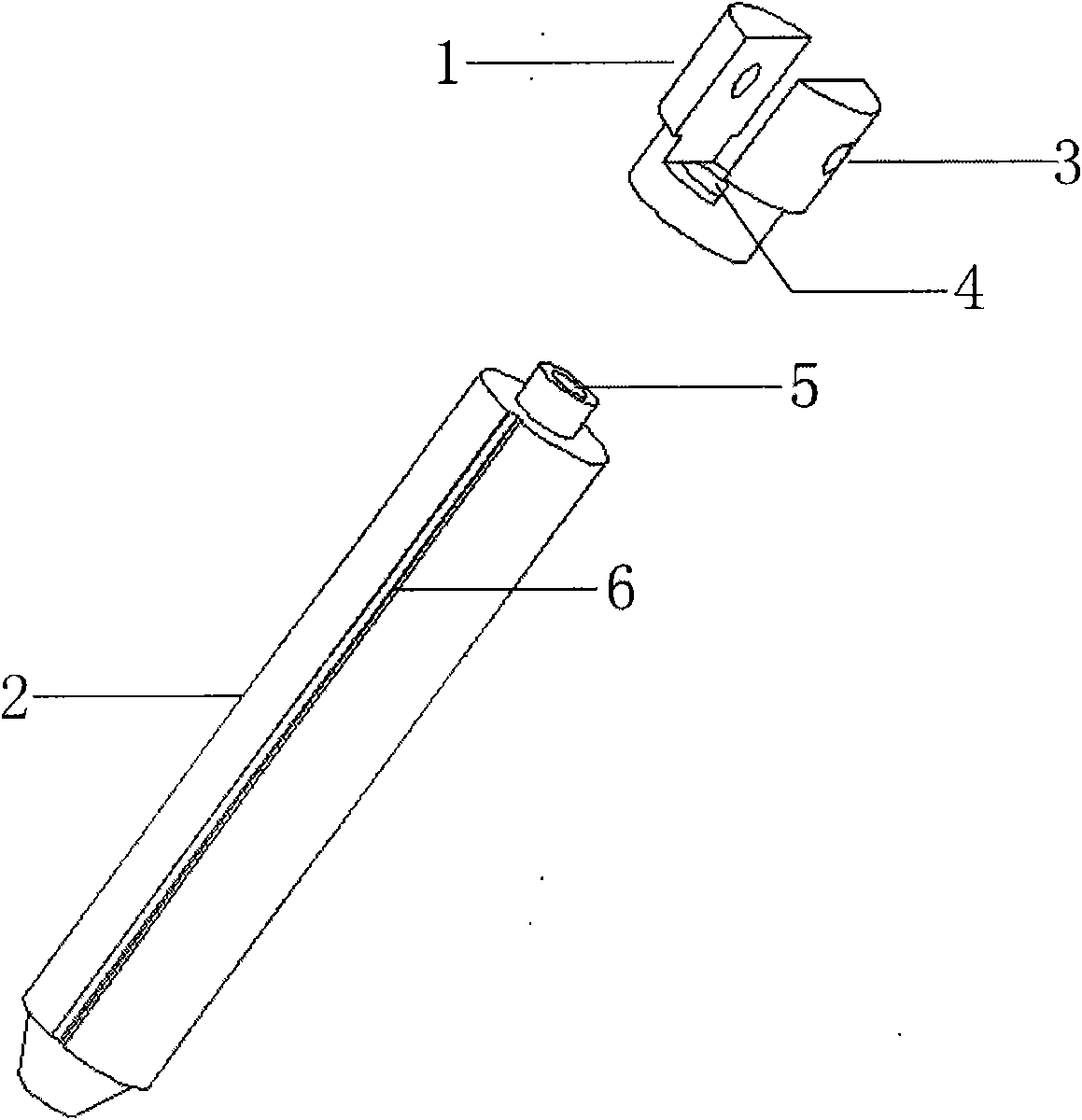

[0007] As shown in the figure: the push rod is composed of a connector 1 and a push rod main body 2; There is an exhaust groove 6 from top to bottom, which is used for exhausting when the push rod is in motion; the connector 1 is made of copper, and the lower end of the connector 1 is made with a connecting hole 4, and the fixing column 5 is inserted into the connecting hole 4 , and connect and fix the connector 1 and the push rod body 2 by punching, the positioning groove in the middle of the upper end of the connector 1 divides the upper end of the connector 1 into two independent ears, and a connecting hole 3 is formed at each end for Fixed push part connection.

[0008] In this way, the push rod is divided into two sections. The material used for the connector 1 is copper, and the material used for the push rod body 2 is high carbon steel. The connector 1 and the push rod body 2 are combined by stamping. When the power is turned on, the push rod body 2 to produce magnetis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com