Method for improving surface cleanliness of spring

A surface cleaning and cleaning tank technology, applied in the field of cleaning, can solve the problems of high noise and inability to clean in large quantities, residual magnetism of springs, adsorption of metal impurities, etc., and achieve the effect of improving product performance and appearance requirements, saving labor, and high cleaning quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

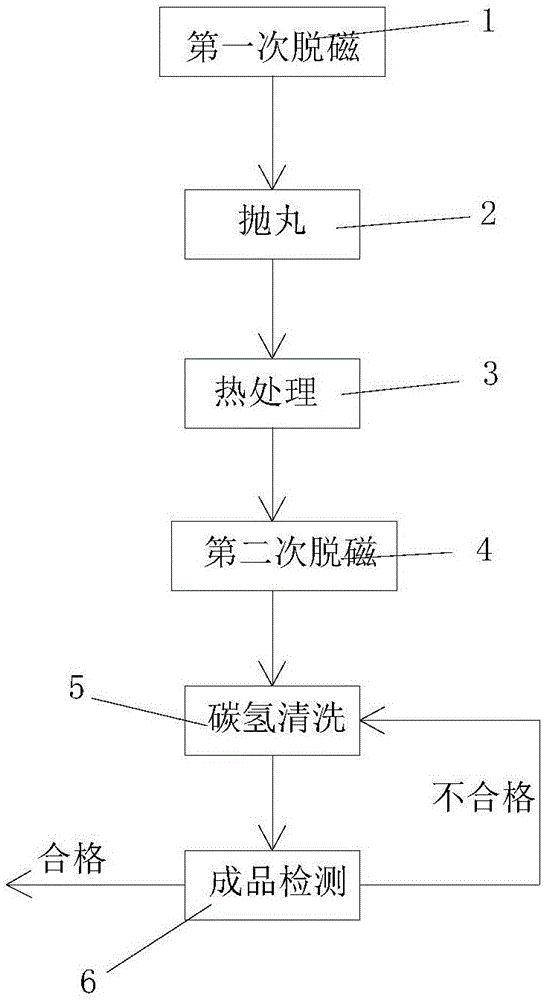

Method used

Image

Examples

Embodiment 1

[0030] Example 1: The first cleaning tank vacuum ultrasonic rough cleaning for 3 minutes + the second cleaning tank vacuum ultrasonic rinsing for 3 minutes, the third cleaning tank vacuum ultrasonic fine cleaning for 3 minutes, the fourth cleaning tank vacuum ultrasonic steam bath washing for 3 minutes, drying for 0.5 minutes and cooling for 1 minute.

Embodiment 2

[0031] Example 2: Rough cleaning in the first cleaning tank for 4 minutes, steam cleaning in the fourth cleaning tank for 3 minutes, drying for 0.5 minutes and cooling for 1.5 minutes.

Embodiment 3

[0032] Example 3: Rinse in the second cleaning tank for 4 minutes, steam wash in the fourth cleaning tank for 3 minutes, dry for 0.5 minutes and cool for 1.5 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com