Asbestos ore tailings treatment device

A processing device and tailings technology, applied in the field of ore, can solve the problems of lower value of asbestos fibers, lower value of recovered products, lower amount of magnetite, etc., and achieve the effects of increasing value, preventing waste and improving economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

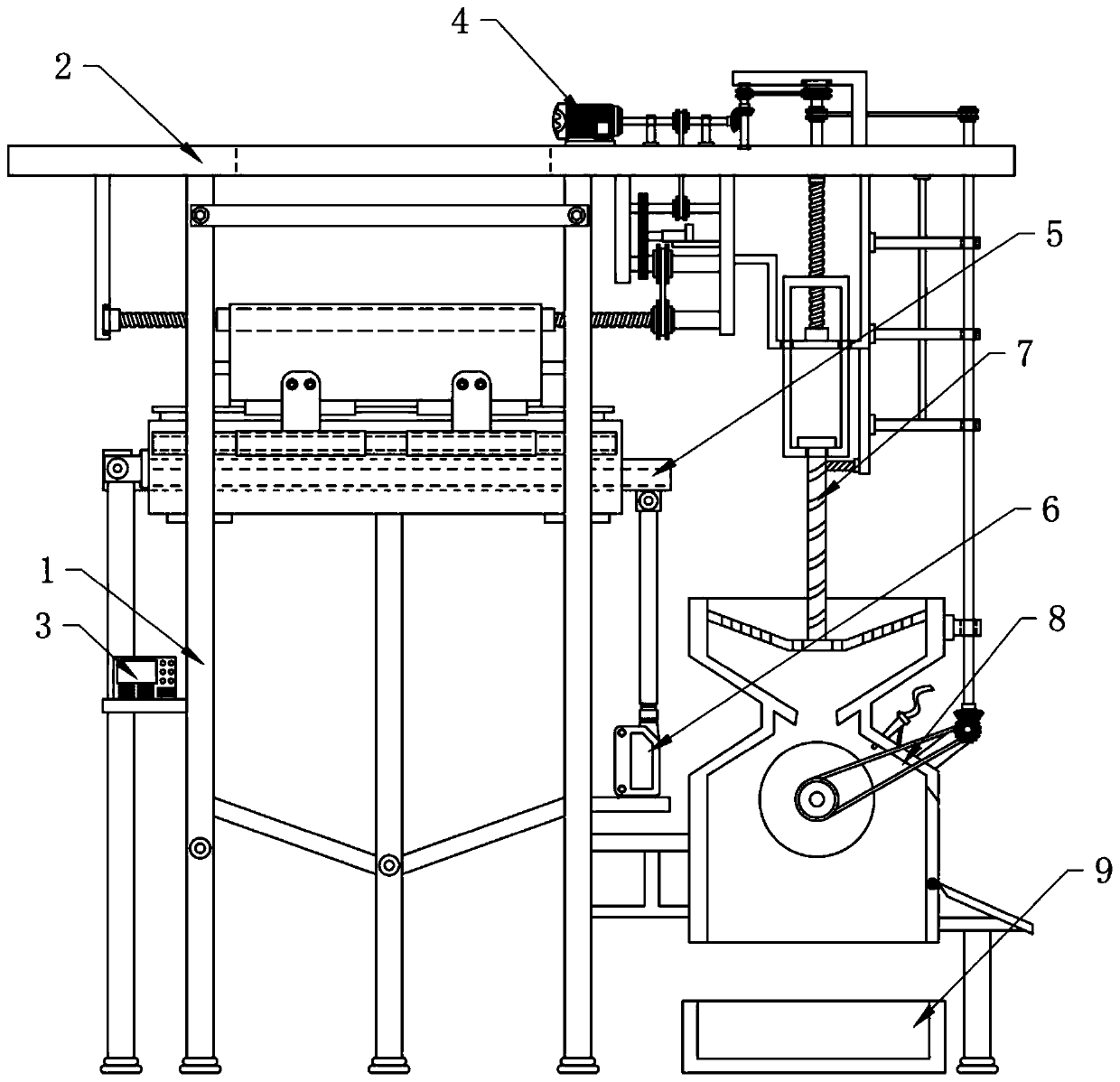

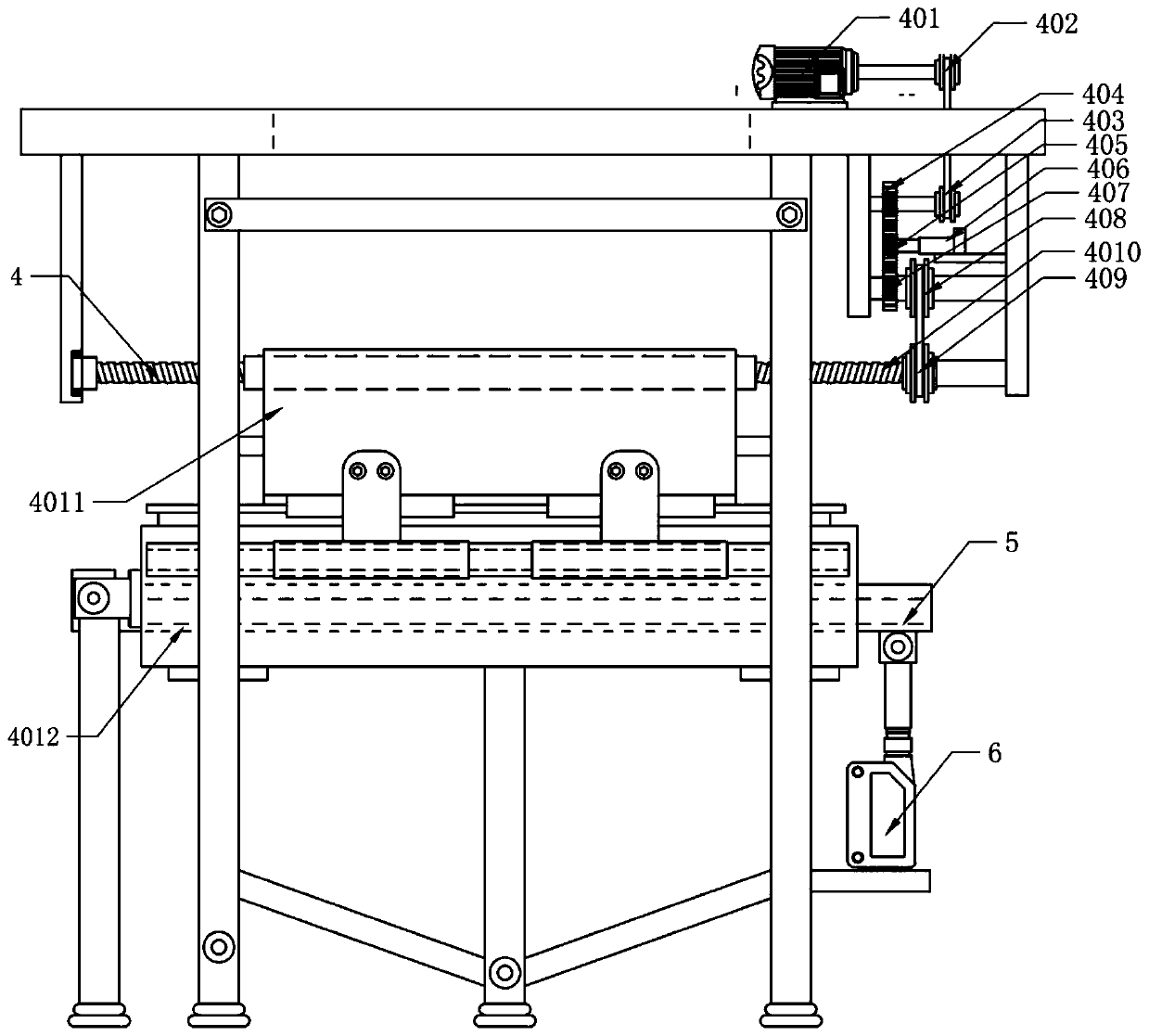

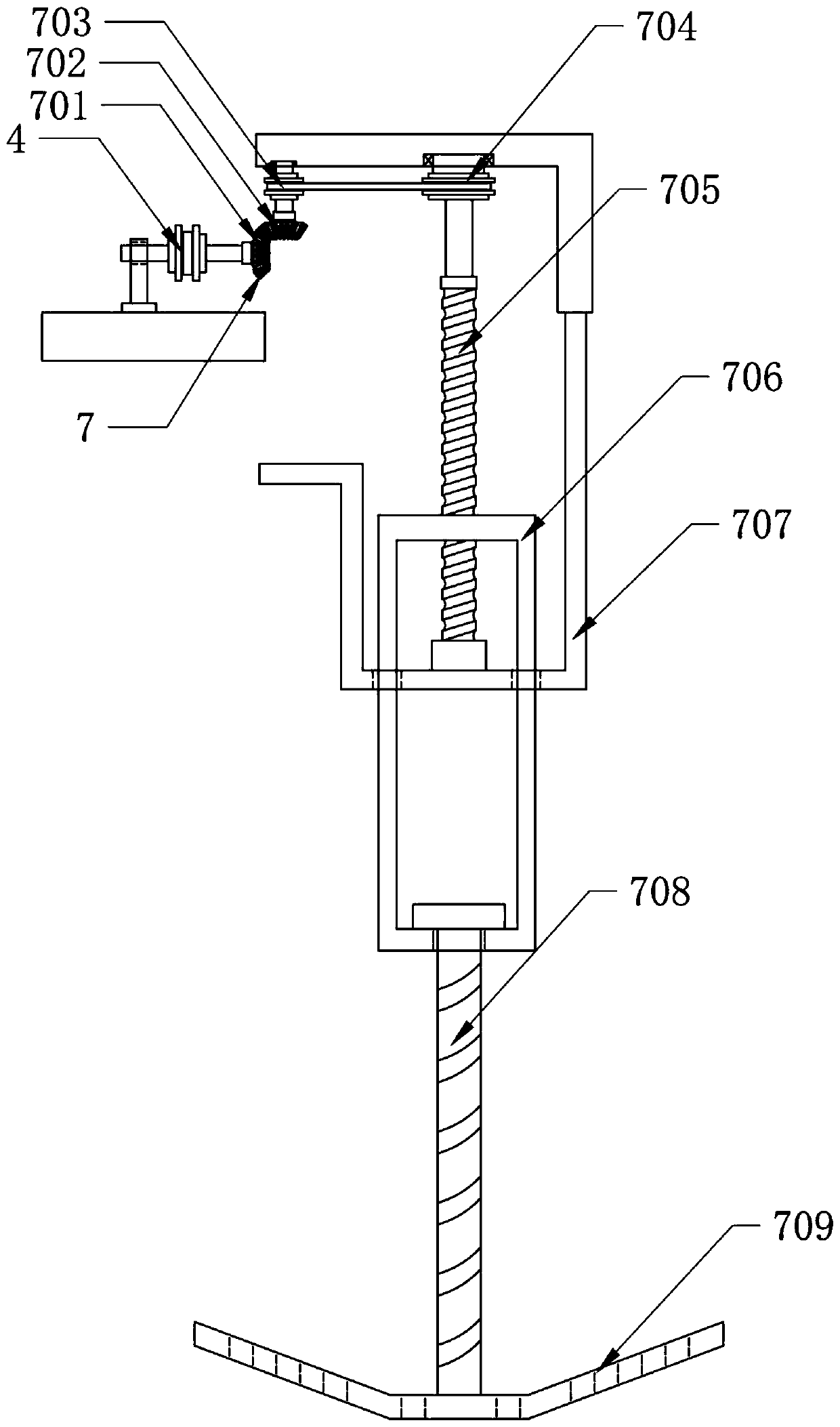

[0031] A kind of asbestos ore tailings treatment device, such as Figure 1-8As shown, it includes support 1, top plate 2, control panel 3, tailings refinement device 4, temporary storage transfer tank 5, cylinder 6, block powder separation device 7, special magnetic separation device 8 and miscellaneous material collection box 9; support 1 The top is connected with the top plate 2 by bolts; the left middle part of the bracket 1 is provided with a control panel 3; the top right side of the top plate 2 is provided with a tailings refinement device 4; The top and middle part of the device 7 is connected with the tailings refining device 4; the middle part of the inner bottom of the tailings refining device 4 is connected with the temporary storage transfer tank 5; the bottom right side of the temporary storage transfer tank 5 is connected with the cylinder 6; the block powder is separated Both the left bottom and the right bottom of the device 7 are connected to the special magne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com