Low-melting-point tin bismuth solder alloy

A solder alloy, low melting point technology, used in welding/cutting media/materials, welding media, welding equipment, etc., can solve the problems of thermal fatigue and poor ductility, limited promotion and application, insufficient welding reliability, etc. Good wettability, improve shear resistance, and ensure the effect of shear strength performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

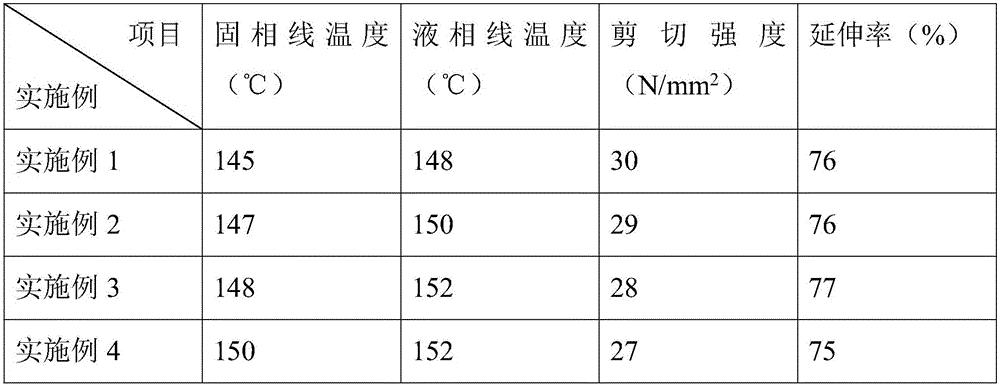

Examples

Embodiment 1

[0019] A low-melting-point tin-bismuth solder alloy, calculated by weight percentage, comprises the following raw materials:

[0020] 20% bismuth, 2.4% titanium, 0.6% nanometer ferric oxide particles, 0.08% vanadium and 0.004% Pr, and the balance is tin. The particle size of the nanometer ferric oxide particles is 50nm.

[0021] Preparation:

[0022] According to Bi, Ti, nanometer Fe in the present embodiment 2 o 3 , V, weight percentage of Pr and Sn Weigh the required raw materials, add them into the furnace, then heat up to 600°C to melt, start timing after complete melting, and keep warm for 120min. During this period, stir with a ceramic rod every 10 minutes to fully homogenize the alloy components. After two hours, take the hot crucible out of the furnace, put it in air to cool down to room temperature (20° C.), and then take it out from the crucible to obtain the low melting point tin-bismuth solder alloy of the present invention.

Embodiment 2

[0024] A low-melting-point tin-bismuth solder alloy, calculated by weight percentage, comprises the following raw materials:

[0025] 23% bismuth, 2.6% titanium, 0.7% nanometer ferric oxide particles, 0.06% vanadium, 0.0003% Co and 0.005% Dy, and the balance is tin. The particle size of the nanometer ferric oxide particles is 10nm.

[0026] According to Bi, Ti, nanometer Fe in the present embodiment 2 o 3 , V, Co, Dy and Sn by weight Weigh the required raw materials, add them into the furnace, and then heat up to 600 ° C to melt, start timing after complete melting, and then keep warm for 120 minutes. During this period, stir with a ceramic rod every 10 minutes to fully homogenize the alloy components. After two hours, take the hot crucible out of the furnace, put it in air to cool down to room temperature (20° C.), and then take it out from the crucible to obtain the low melting point tin-bismuth solder alloy of the present invention.

Embodiment 3

[0028] A low-melting-point tin-bismuth solder alloy, calculated by weight percentage, comprises the following raw materials:

[0029] 10% bismuth, 3.0% titanium, 0.8% nanometer ferric oxide particles, 0.0005% Co, 0.006% Nd, 0.1% vanadium, and the balance is tin. The particle size of the nanometer ferric oxide particles is 10nm.

[0030] The preparation method of the low melting point lead-free solder in this embodiment is the same as the method described in embodiment 2, the only difference is that the weight percentages of the components of the lead-free solder alloy are weighed according to the proportions in this embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com