Full-automatic straight type sock stitching machine

A sewing machine and fully automatic technology, applied in the field of sewing machine and automatic straight sock sewing machine, can solve the problems of large height error, time-consuming, low work efficiency, etc., to improve work efficiency, ensure production quality, Simple to use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

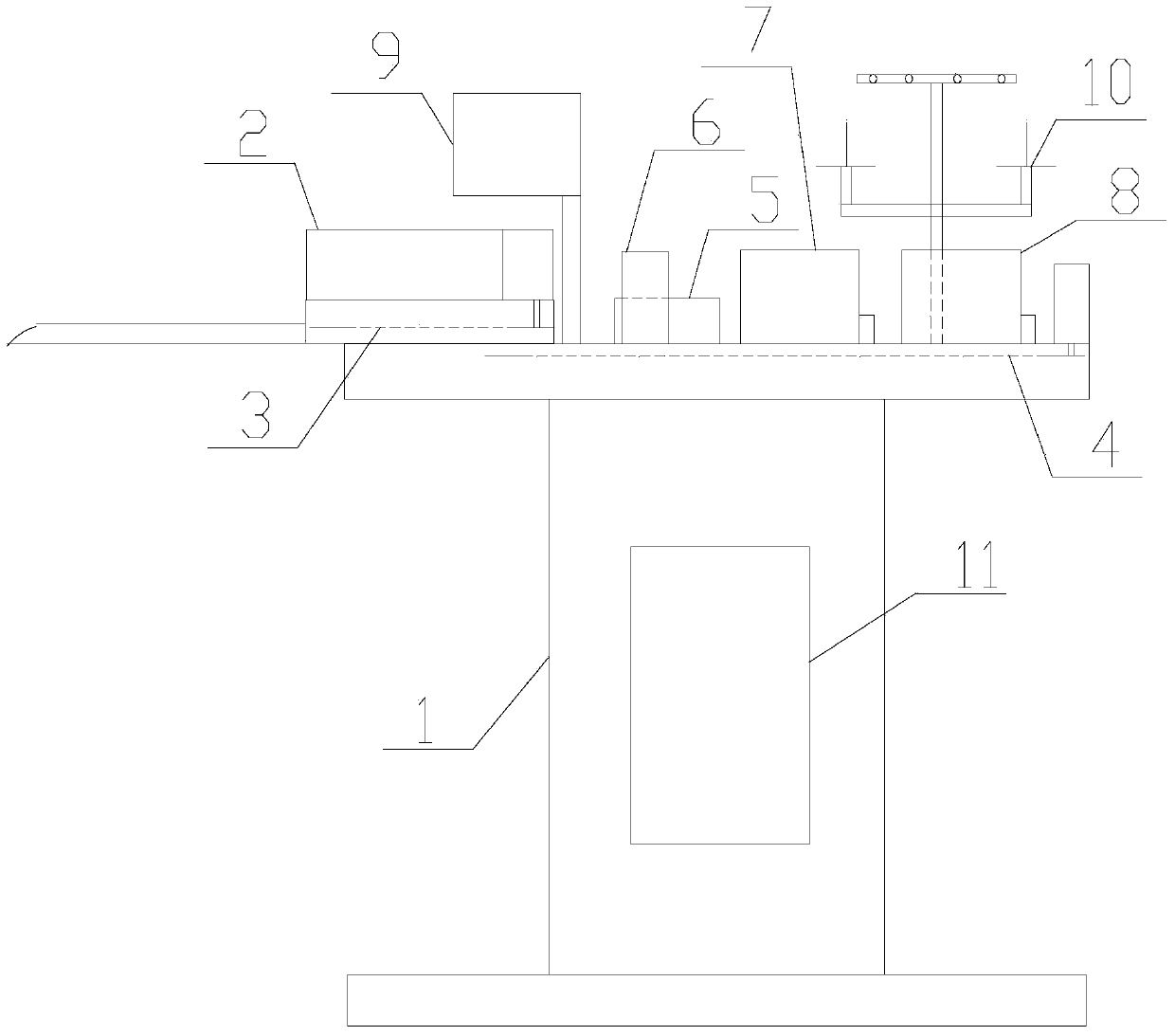

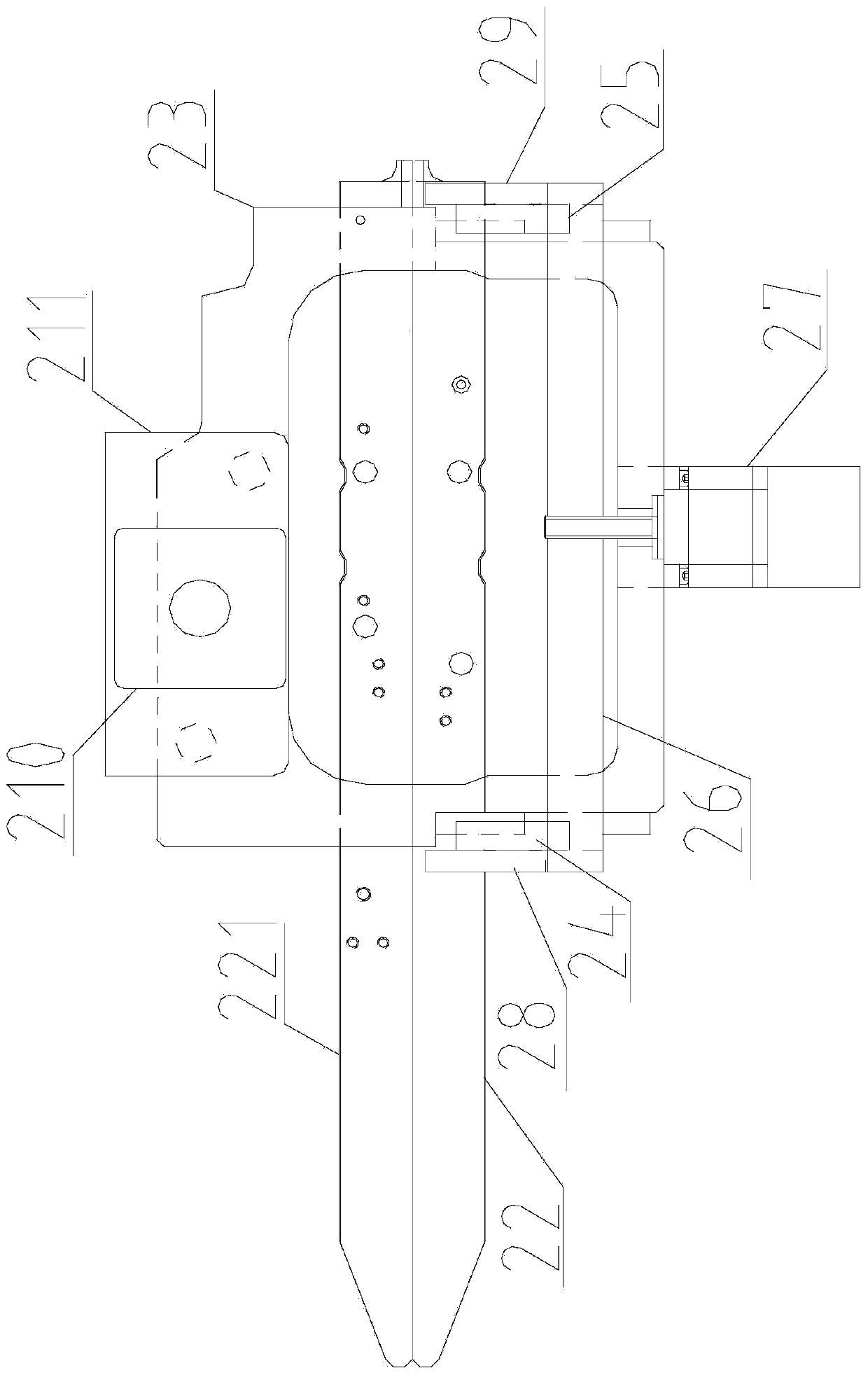

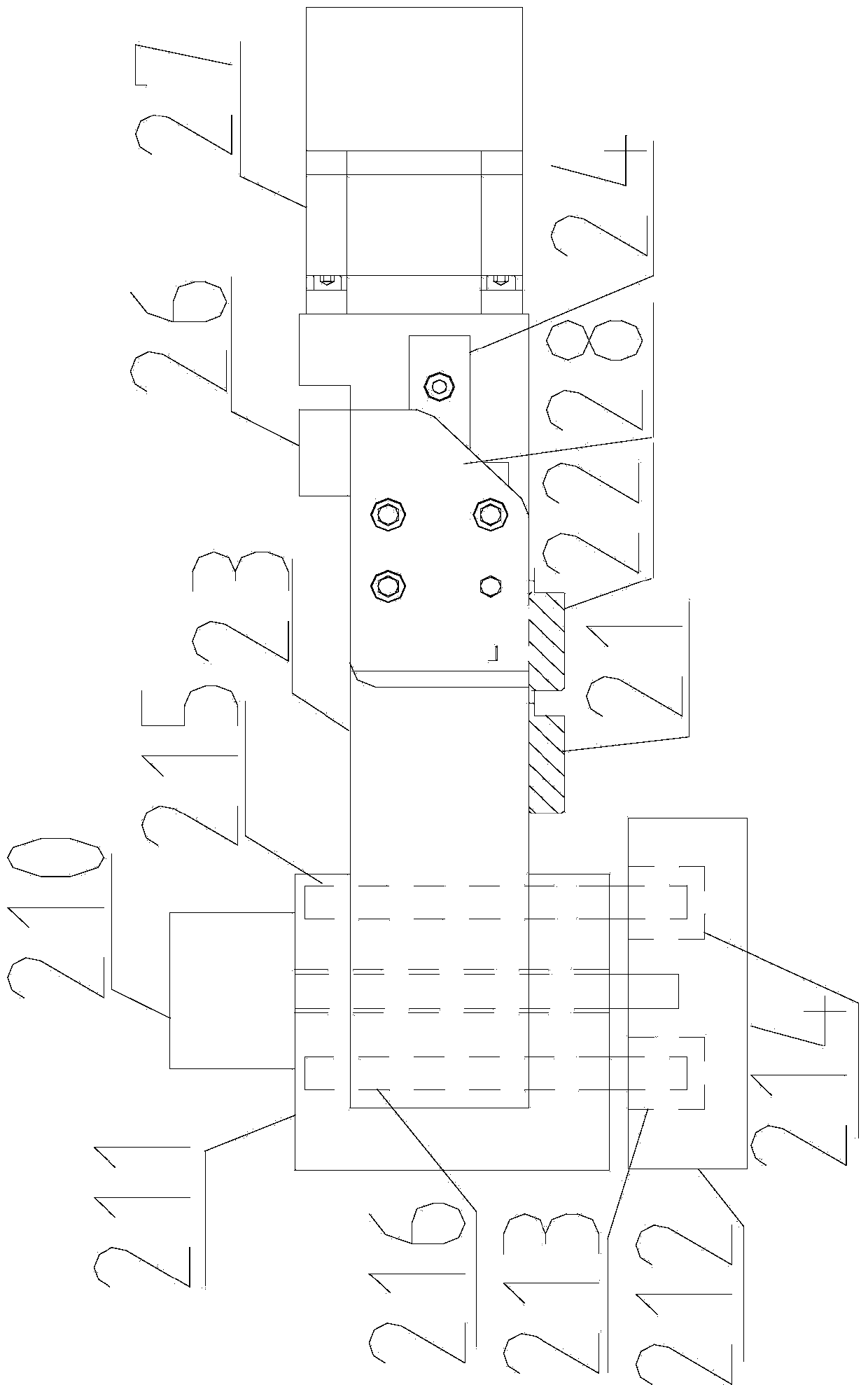

[0021] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6, a fully automatic straight sock sewing machine according to the present invention, comprising a frame body 1, a guide device 2, a first conveying chain device 3, a second conveying chain device 4, a main motor 5, a cutter device 6, a first Machine head 7, second machine head 8, computer 9, wire rack 10 and electrical box 11, described guide mouth device 2, cutter device 6, first machine head 7 and second machine head 8 are all located at support body 1 and arranged in order, the bottom of the mouth guide device 2 is provided with a first conveyor chain device 3, and the second conveyor chain device 4 is located at the cutter device 6, the first machine head 7 and the second machine head 8 Below, the frame body 1 is provided with a computer 9, a main motor 5 and a wire rack 10, the front of the main motor 5 is provided with a computer 9, and the rear of the main motor 5 is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com