Bar tacking machine with needle position safety detection sensor, control method and sensing plate thereof

A technology of safety detection and control method, applied in the field of sensors, can solve the problems such as the inability to perceive the absolute position of the needle deviating from the needle position, the inability to judge the absolute mechanical position of the needle when the power is turned on, and unsafe hidden dangers, so as to achieve safe movement. Control, prevent the collision of the needle, and ensure the effect of safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention has a tacking machine with a needle position safety detection sensor. The tacking machine adopts a direct-drive motor as power, and the motor and the main shaft of the tacking machine are coaxially installed and run synchronously; the needle position safety detection sensor includes a needle position sensing sheet 3, Encoder 2, such as Figure 7 As shown, an encoder 2, a needle position sensor 3, and a fixing piece 4 are sequentially arranged on the main shaft of the tacking machine 1, and the fixing piece 4 axially fixes the encoder 2 and the needle position sensing piece 3 on the main shaft of the tacking machine 1 ; Encoder 2, needle position sensing piece 3 outer cover is provided with shell 5.

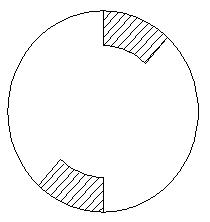

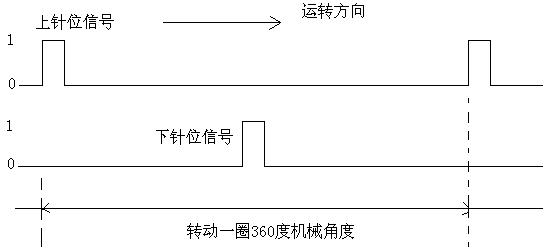

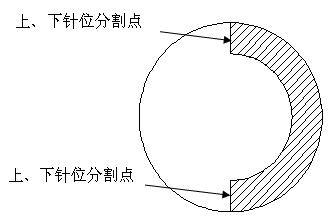

[0042] Such as image 3 As shown, the sensing area of the needle position sensing sheet 3 ( image 3 The black area in ) covers a part of the sensing sheet, the sensing area is a semi-circular area, and the semi-circular area is bounded by the angl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com