Fabric tiling device capable of fabricating looping of linking machine

A technology for sewing disc machines and fabrics, which is applied to sewing machine components, knitting, cloth feeding mechanisms, etc., can solve the problems of visual fatigue, low work efficiency, manual operation fatigue of operators, etc. Sophisticated effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

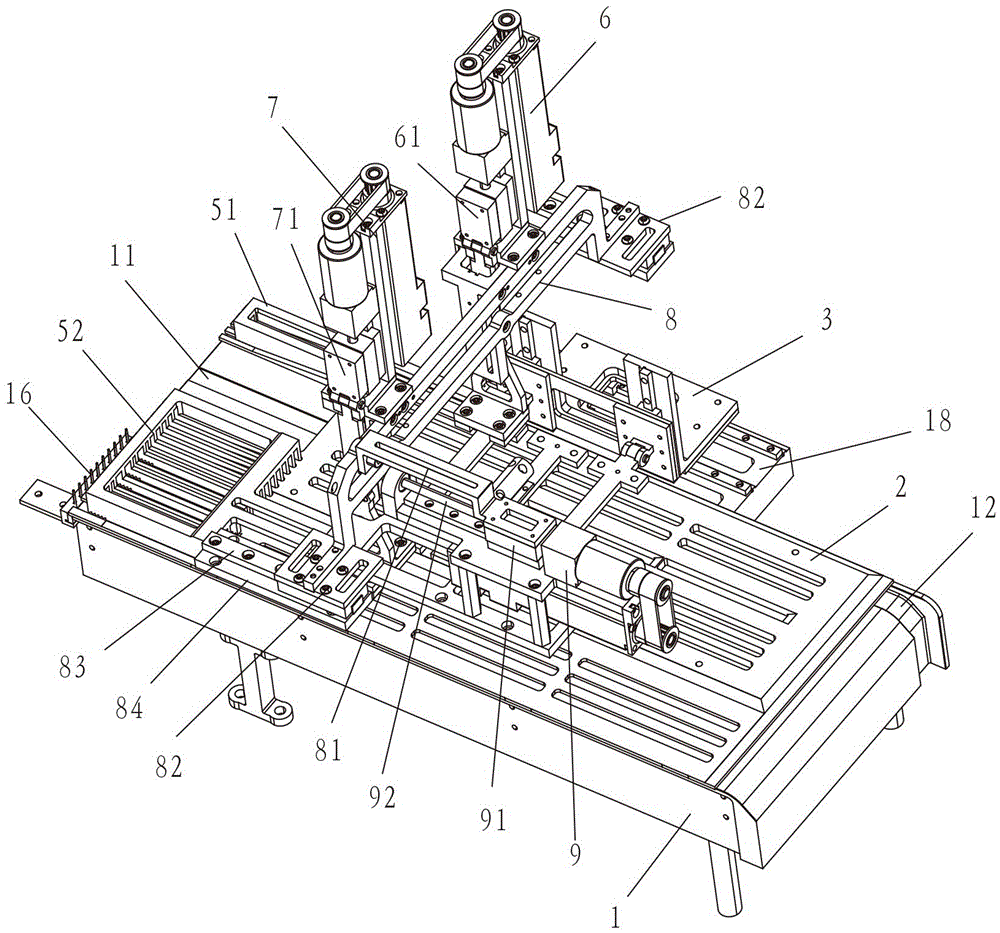

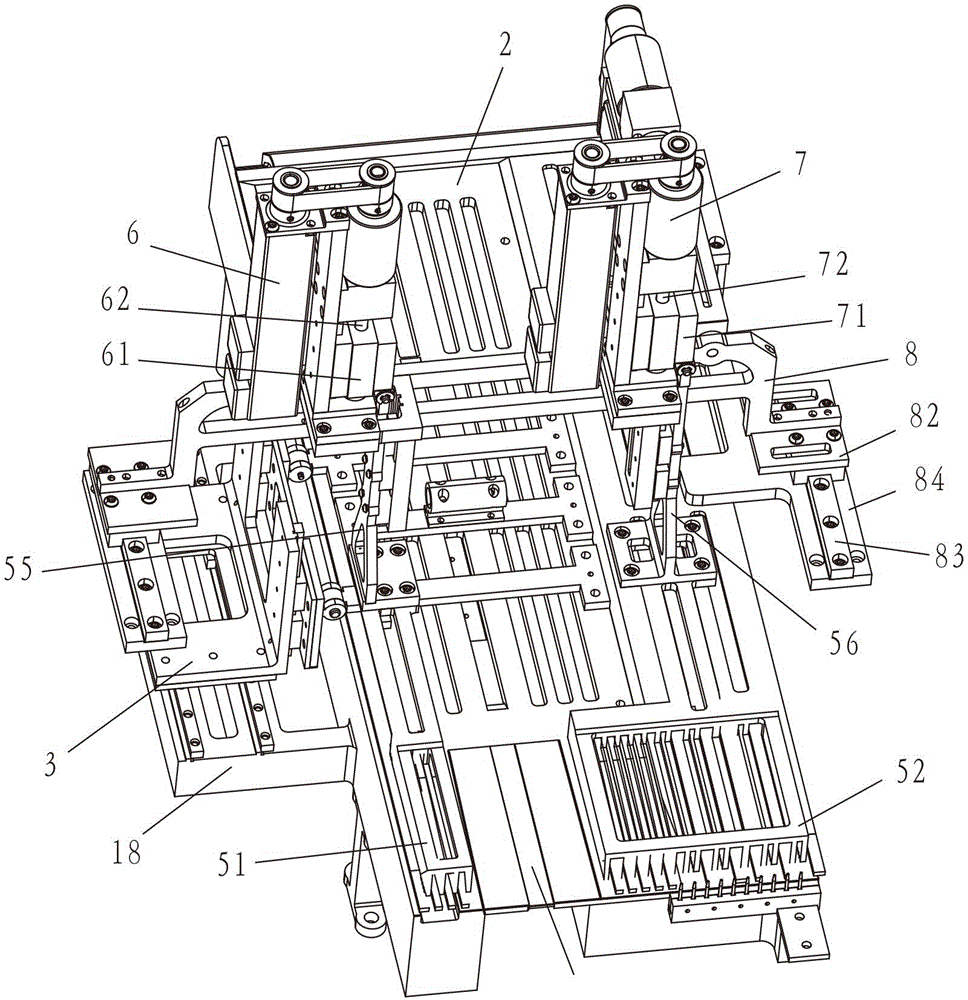

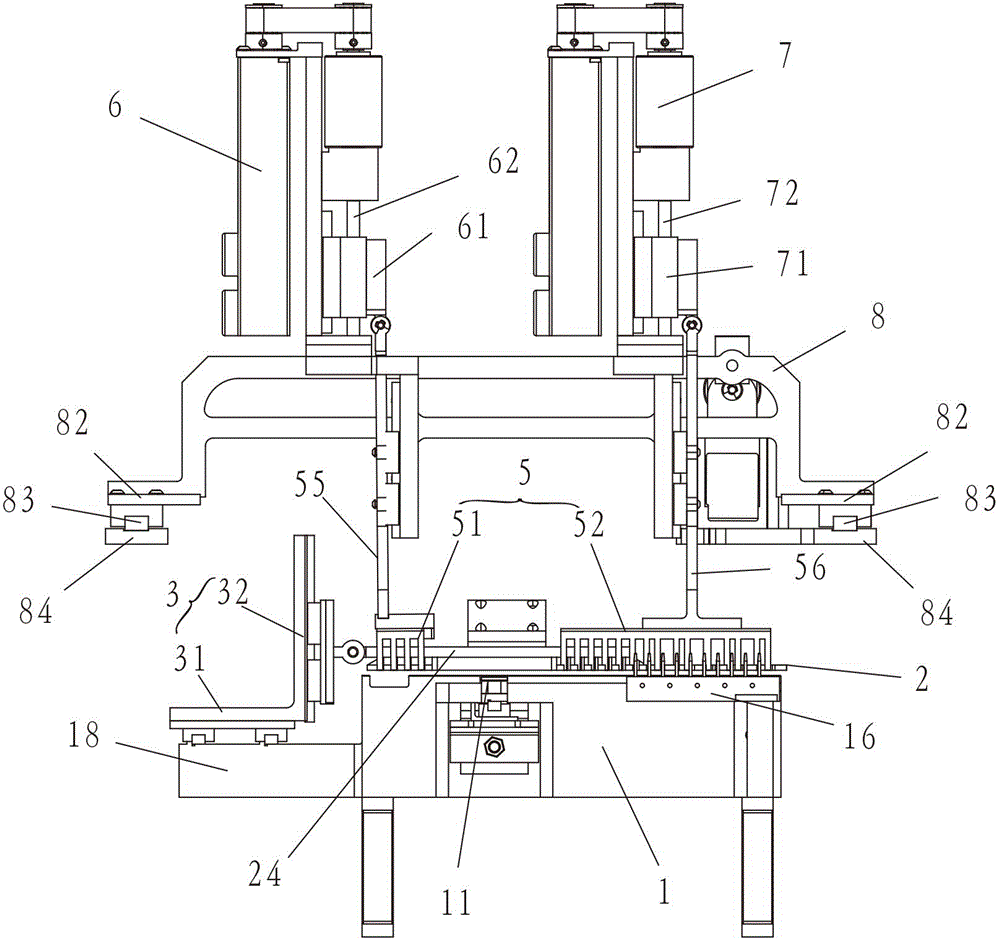

[0025] See attached picture. This embodiment includes a workbench 1, which is provided with a strip-shaped notch 11; the rear side of the workbench 1 is provided with a rectangular groove 12 that runs through the entire table; the strip-shaped notch 11 and the rectangular groove 12 are arranged in parallel, the two sides of the elongated notch 11 are provided with a second chute, the notch is provided with a second movable plate 13, and the second movable plate 13 cooperates with the second chute; the left end of the workbench 1 is provided with a vertical Straight guide rail 14, the guide rail 14 is provided with the first movable block 15 that matches with it; The positioning rake 16 is fixed on the first movable block 15, and the positioning rake 16 is provided with the positioning pin 17; The workbench 1 And the right end of the rectangular groove 12 is a smooth arc structure.

[0026] The workbench 1 described in this embodiment is used to place the fabric, and the fabri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com