Toe end closing apparatus

A suture device and sock opening technology, applied in the direction of sewing machine control devices, sewing equipment, sewing machine components, etc., can solve the problems of complex structure, small angle, large volume, etc., and achieve the effect of simple overall structure, simple structure, and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Below in conjunction with accompanying drawing and embodiment the present invention is described in detail:

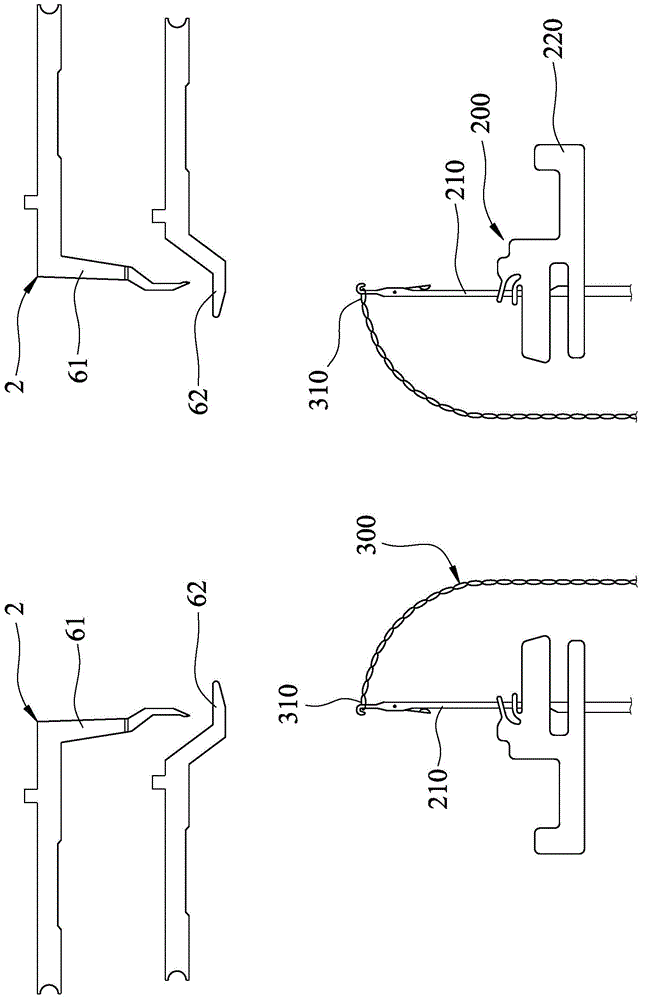

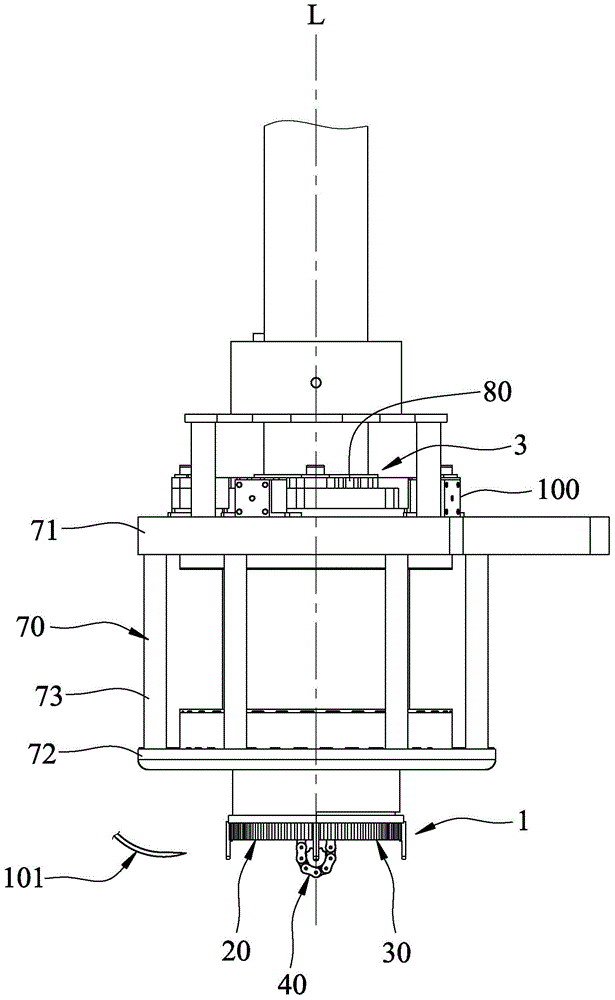

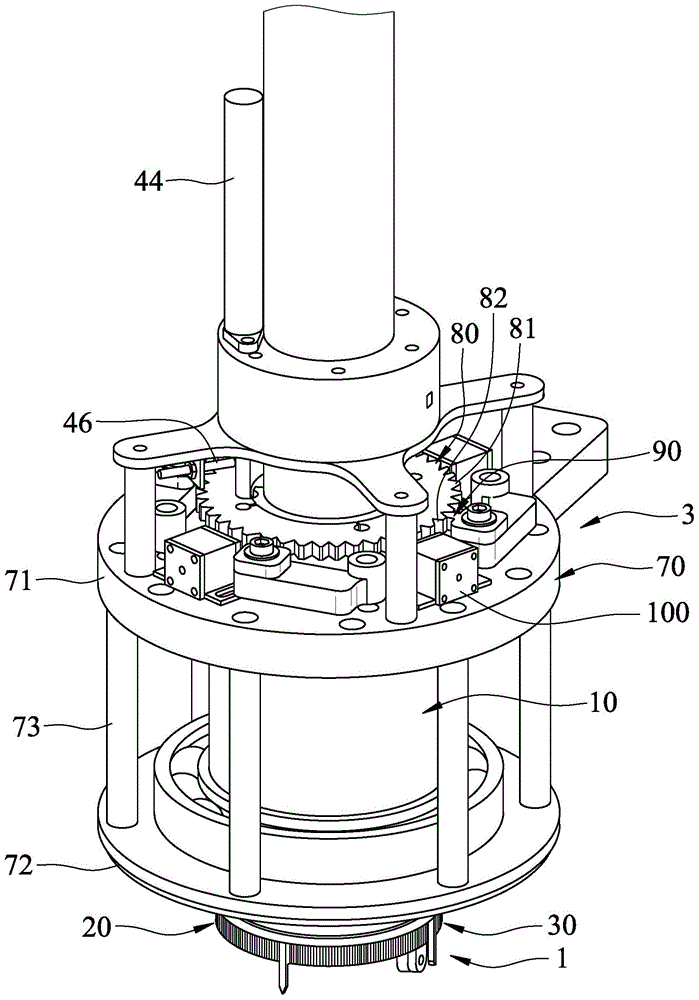

[0042] refer to figure 1 , figure 2 and image 3 , a preferred embodiment of the sock opening sewing device of the present invention can sew a sock opening 310 of a hollow tubular sock body 300 woven by a sock knitting machine 200. The sock knitting machine 200 includes several yarns Needle 210 and several sinkers 220, the sock opening sewing device includes a sewing unit 1, a sock body transfer unit 2 and a rotation control unit 3.

[0043] Coordination parameters Figure 4 to Figure 7 The sewing unit 1 has a main body 10 extending along an axis L, a fixed reed 20 fixed at the bottom of the main body 10, a movable reed 30 pivotally arranged on the fixed reed 20, a movable reed capable of driving the Movable steel reed 30 is relative to this fixed steel reed 20 and is 180 degree unfolding or 0 degree overlapping seaming driving group 40, an auxiliary drivin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com