Integrated sock making machine with binding-off function

An integrated and functional technology, which is applied to sewing machine components, needle holders for sewing machines, and stitching machines connecting knitted fabrics, etc., can solve the problems of reduced work efficiency, troublesome operation, time-consuming and laborious, etc., to improve production efficiency and save manpower. physical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

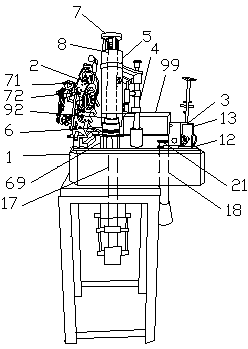

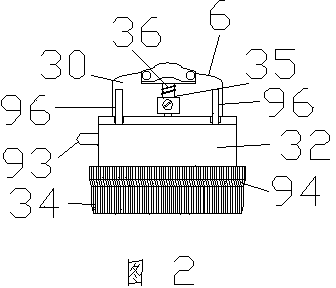

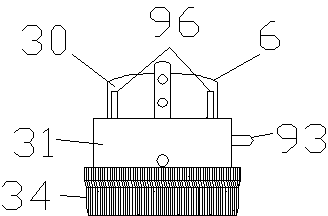

[0020] like figure 1 As shown in -7, a kind of all-in-one hosiery machine with toe stitching function of the present embodiment includes a workbench 1 and a sock knitting machine 2 installed on the workbench 1; Seaming machine 3 with sock sewing function, rotatable column 4 for transferring socks, working disc 69 for providing sock knitting and sock turning place, sock discharge platform 21 for exporting socks and solenoid valves for controlling all cylinders Control box 99; the rotatable column 4 is equipped with a sock feeding tube 5; the sock feeding tube 5 is equipped with a sock suction tube 8; the lower end of the sock suction tube 8 is equipped with a seam for socks transmission and export Disk 6, the upper end of the sock suction tube 8 is movably equipped with a top cover 7, the top cover 7 can move up and down according to different working conditions; the sewing head machine 3 is connected with the servo motor 98, driven by the servo motor 98; the working On the pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com