Sock toe sewing machine with air power source

An aerodynamic, seaming machine technology, applied in the field of sock sewing machines, can solve problems such as difficulty in placement, socks falling, and inability to be cleaned, and achieve the effects of improving feeding stability, reducing labor intensity, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

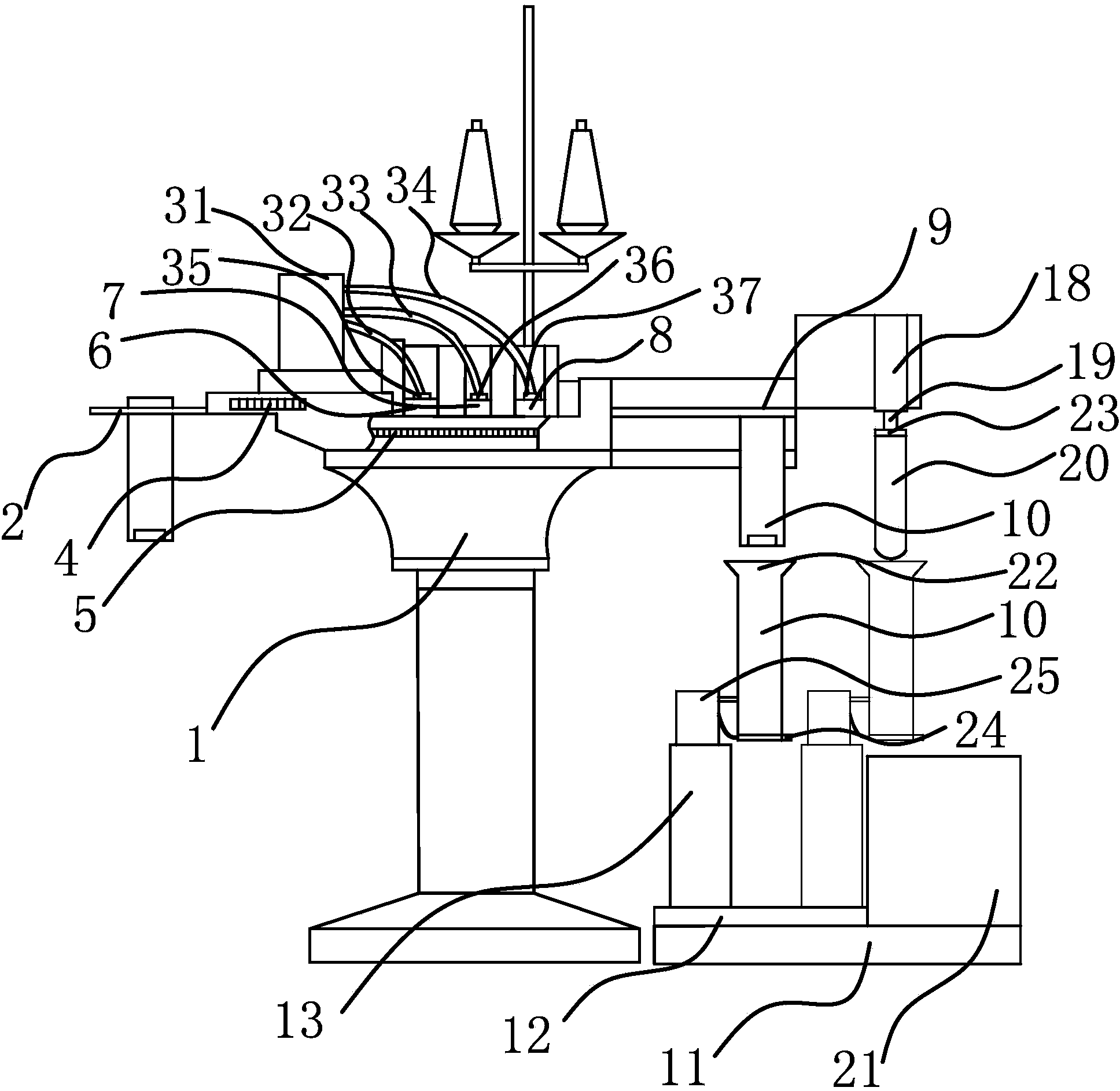

[0028] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

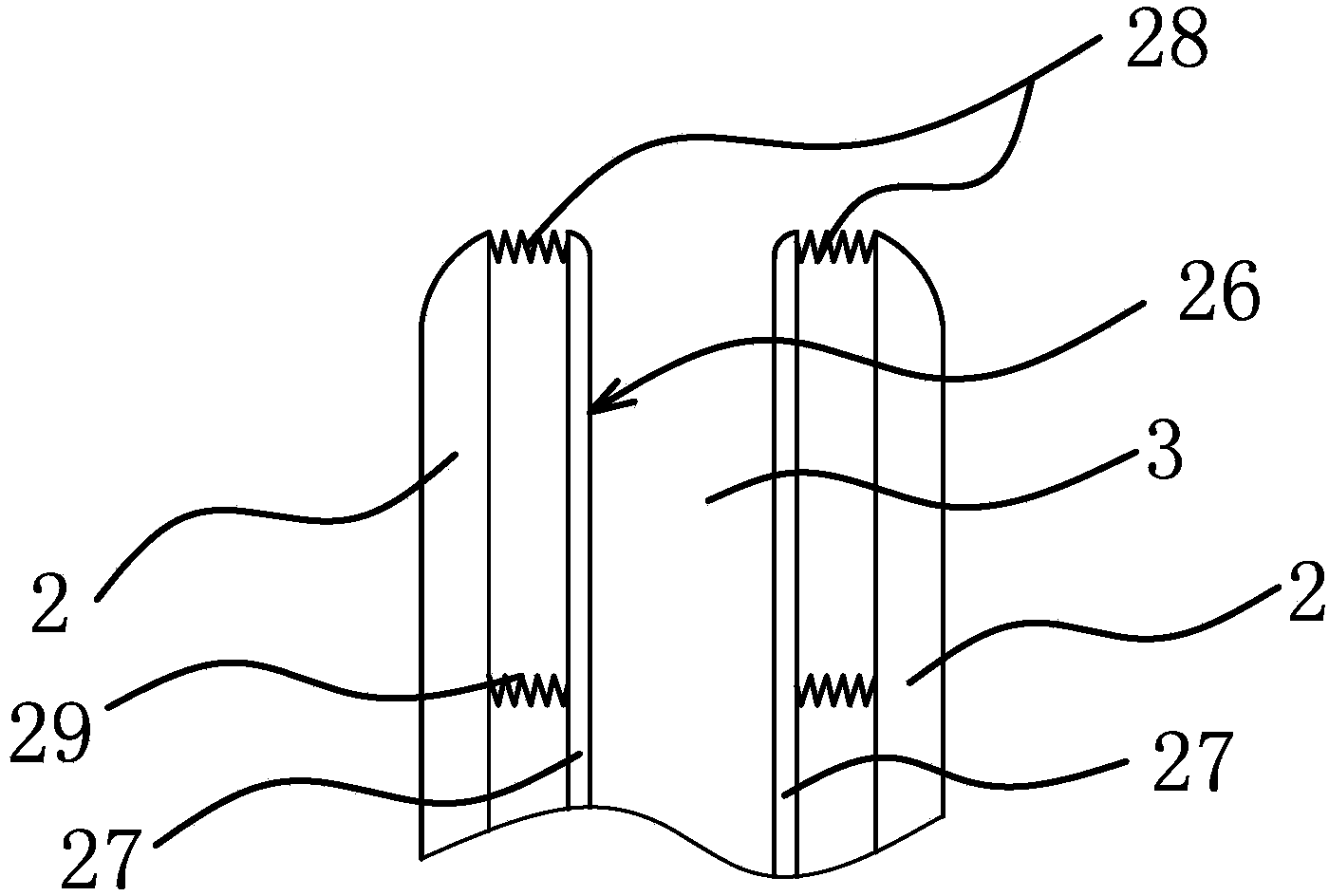

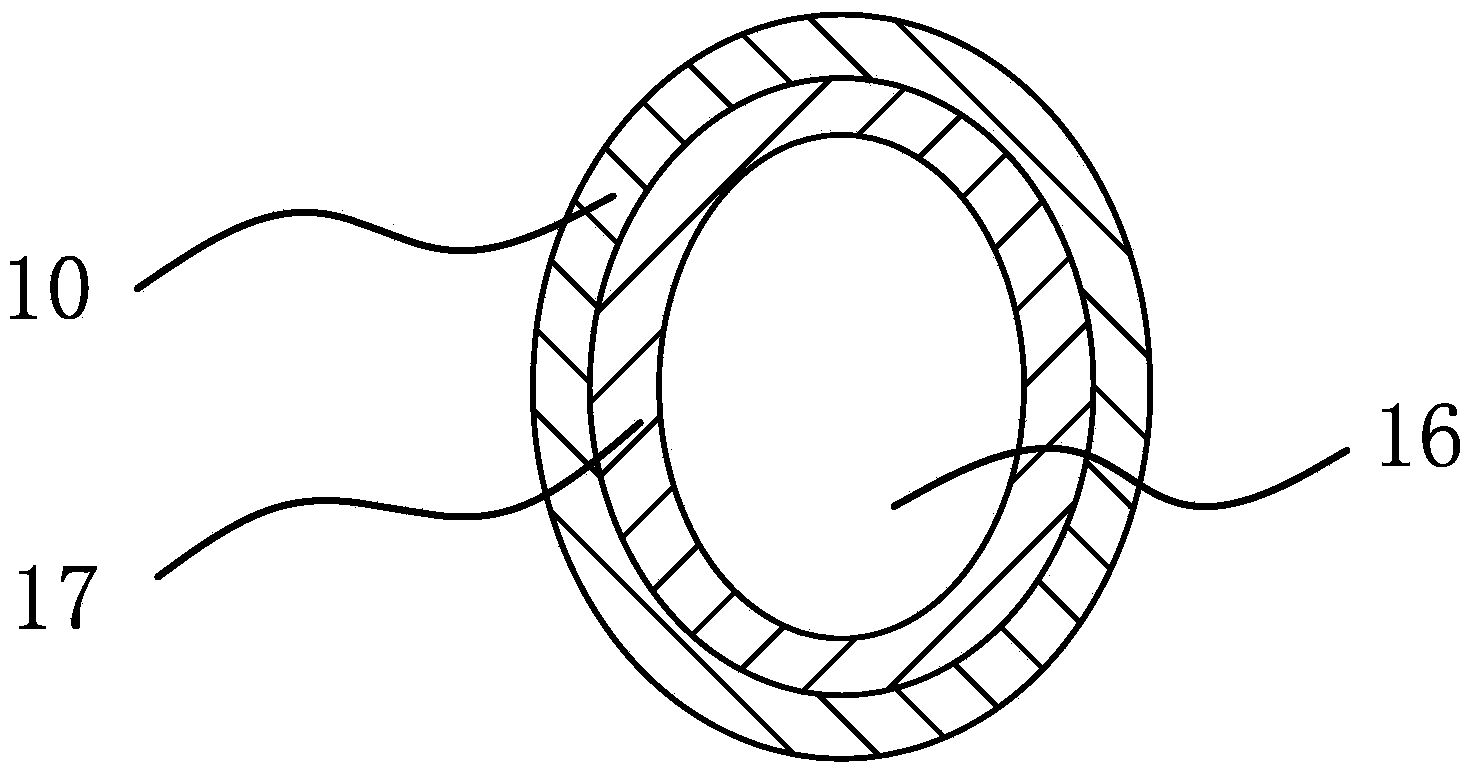

[0029] like figure 1 , figure 2 As shown, the sock sewing machine with an air power source includes a frame 1, and a feeding device for conveying socks 30 is arranged on the frame 1. The feeding device includes two guide rails 2 fixed on the left end of the frame 1, two The guide rails 2 are arranged at intervals and a gap 3 for clamping the socks 30 is formed between them. Specifically, there is an elastic layer 26 between the inner surfaces of the two guide rails 2 , and the length direction of the elastic layer 26 is the same as that of the guide rails 2 . Elastic layer 26 comprises guide rod 27, stage clip one 28 and stage clip two 29 in the present embodiment, and guide rod 27 is arranged along the lengthwise direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com