Cloth-feeding device of sewing machine

A cloth feeding device and sewing machine technology, which is applied in the direction of sewing machine control devices, sewing machine components, sewing machine needle seats, etc., can solve the problems of inability to increase the speed, decrease in the quality of sewing products, and inconsistent feeding volume, and achieve the sewing pitch roughly the same effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

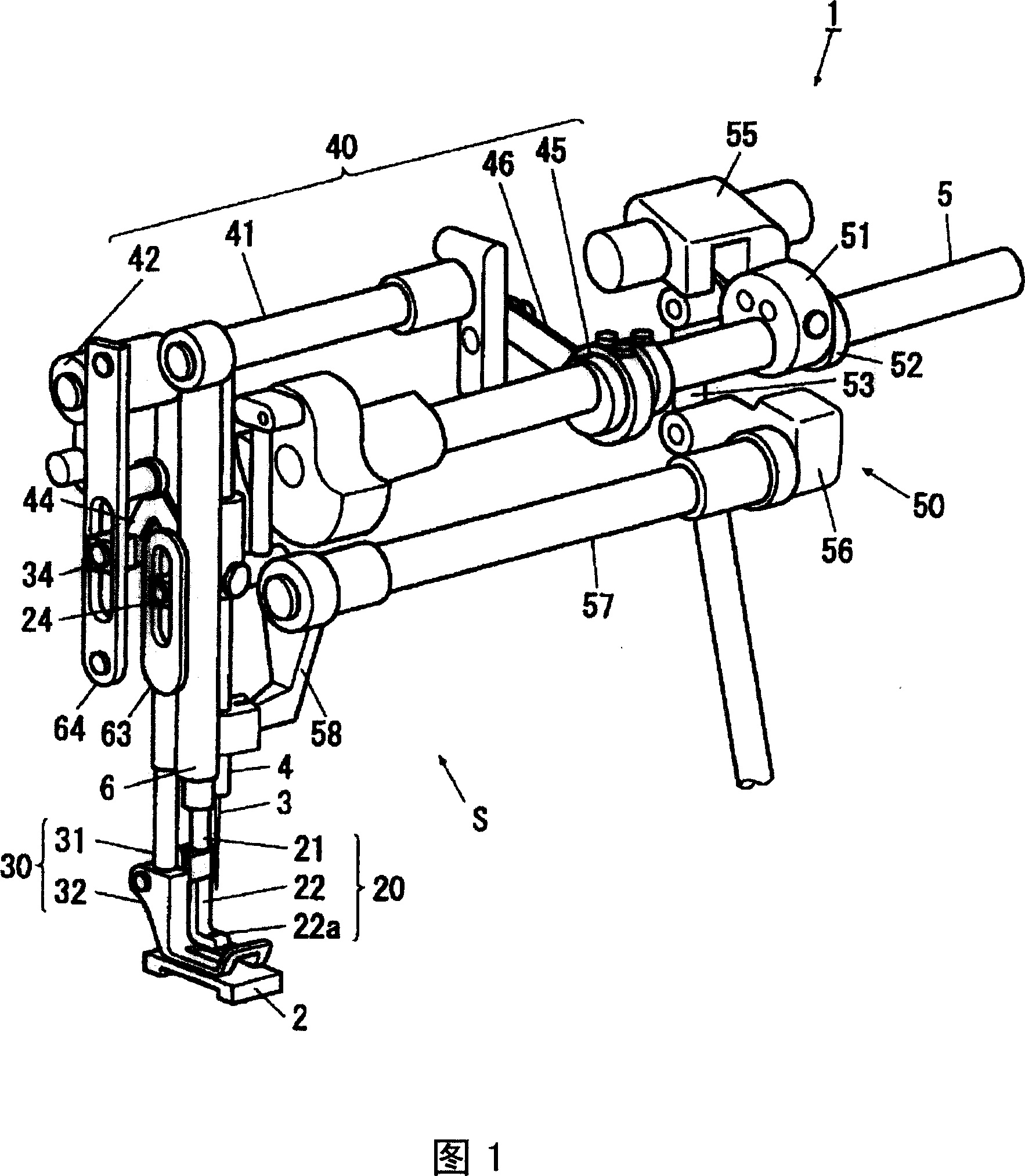

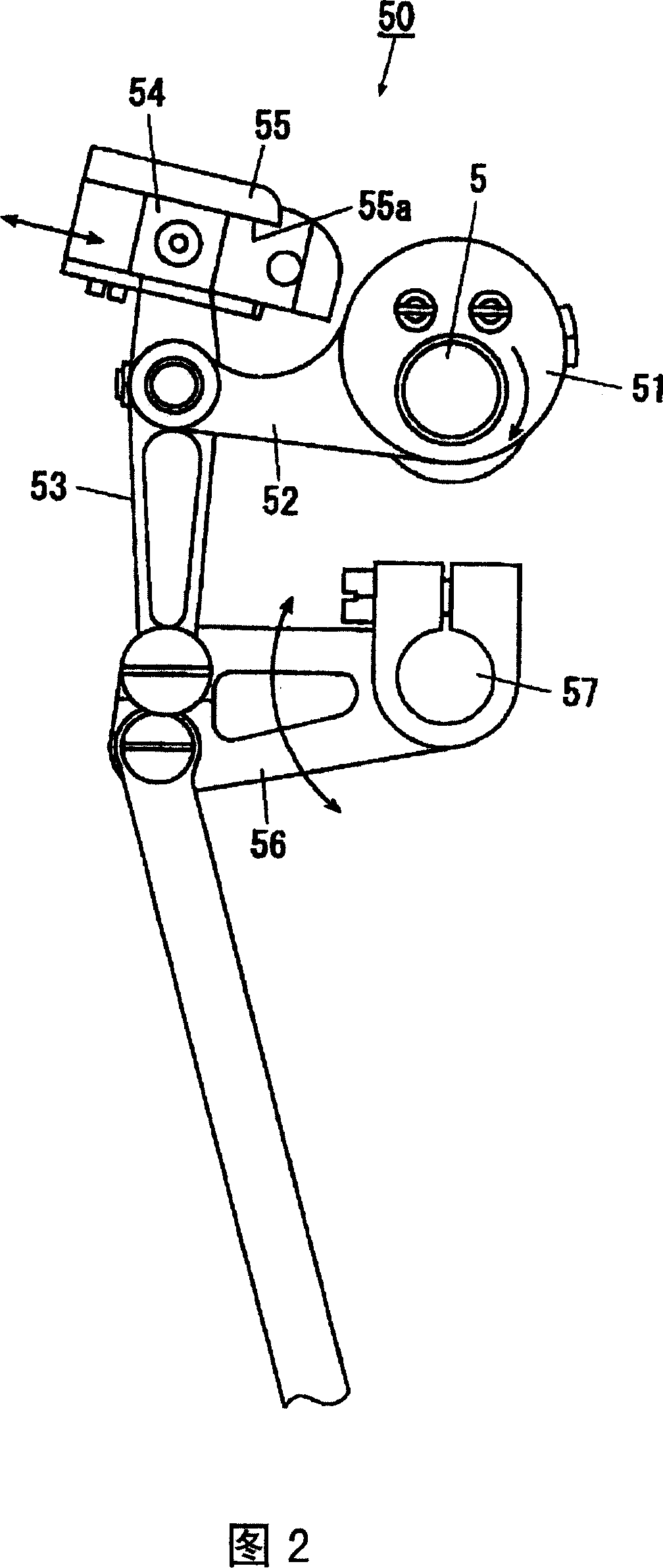

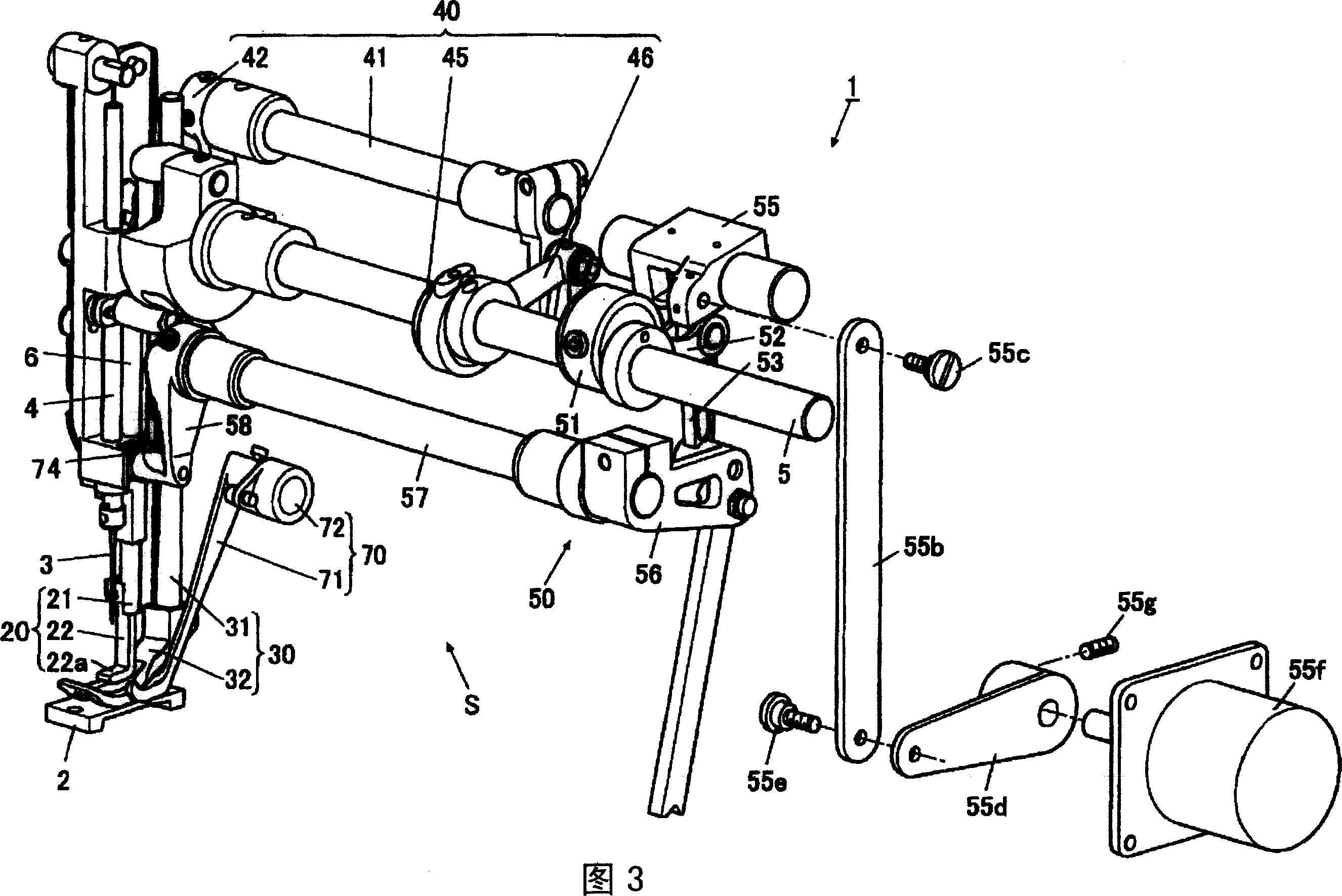

[0023] Next, the best mode of the cloth feed device of the sewing machine will be described in detail with reference to the drawings.

[0024]

[0025] As shown in FIGS. 1 to 4 , the cloth feeding device 1 of the sewing machine has an upper cloth feeding part 20 that moves in the cloth feeding direction in a state of contacting the cloth as the sewing object on the needle plate 2 from above to perform cloth feeding. The conveying of the cloth; the cloth pressing part 30, which has a presser foot 32 that presses the cloth toward the needle plate 2 from above; Carry out the reciprocating action in the up and down direction; the second action mechanism 50 (needle feeding mechanism, referring to Fig. 3 ), it makes the upper cloth feeding part 20 carry out the reciprocating action on the cloth feeding direction; When the cloth part 20 and the cloth pressing part 30 respectively descend, by abutting against them from below, the respective lower limit positions are determined, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com