Sewing quality control in sewing machine

A sewing machine and sewing technology, applied in the direction of sewing machine components, sewing machine needle seats, sewing machine metering devices, etc., can solve problems such as defective products, unavailable inspection of defective products, evaluation of thread tightness, etc., and achieve the effect of improving sewing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

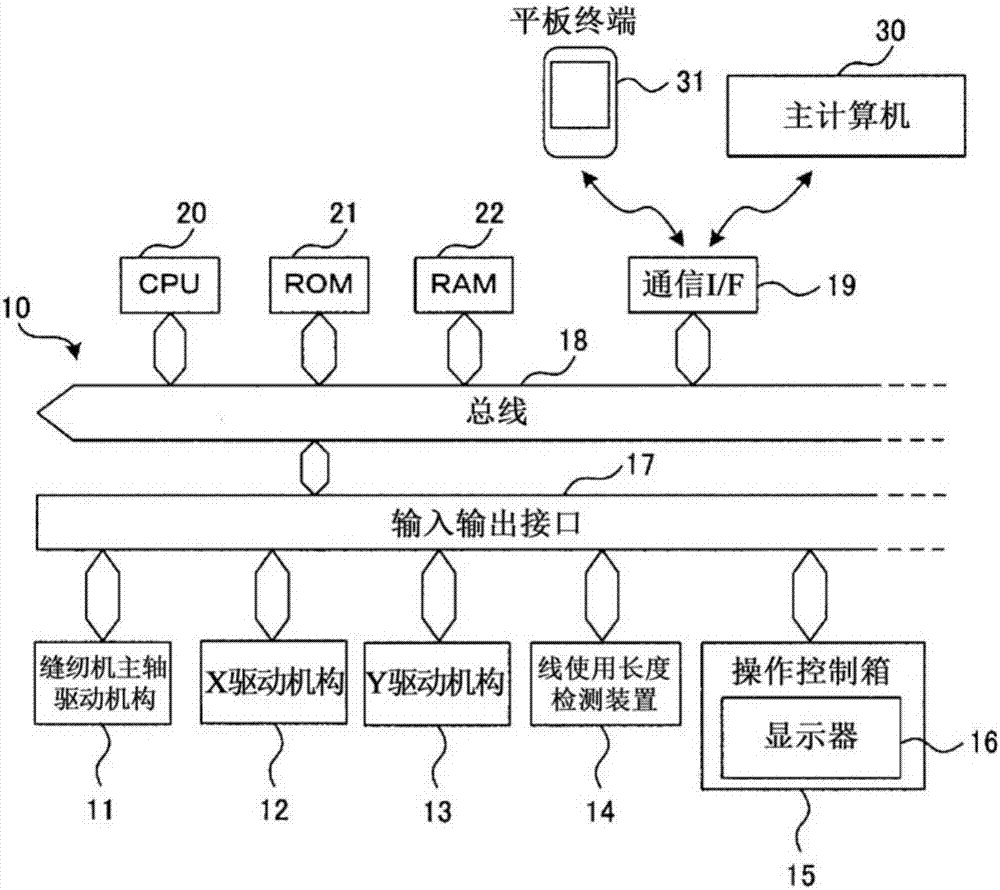

[0021] figure 1 It is a block diagram schematically showing the system configuration of the embroidery sewing machine 10 according to one embodiment of the present invention. The mechanical structure of the embroidery sewing machine 10 may be any known structure such as a pattern sewing machine, and the illustration of the mechanical structure is omitted. The embroidery sewing machine 10 may be, for example, a single-head embroidery sewing machine having only one sewing head, or a multi-head embroidery sewing machine having a plurality of sewing heads. As known, this embroidery sewing machine 10 has a sewing machine main shaft that is rotationally driven by a sewing machine main shaft driving mechanism 11, and drives needle bars (not shown) of each sewing head up and down in accordance with the rotation of the sewing machine main shaft, thereby making The upper thread attached to the needle bar and the lower thread provided on the lower thread hook are intertwined to sew the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com