Sewing machine and method of controlling operation of the same

A sewing machine and sewing machine head technology, applied in sewing machine components, needle holders for sewing machines, sewing machines for leather products, etc., can solve problems such as difficulty in mass production of sewing objects, and achieve the effect of reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0092] Embodiments of the sewing machine and its drive control method of the present invention will be described in detail below in conjunction with the accompanying drawings.

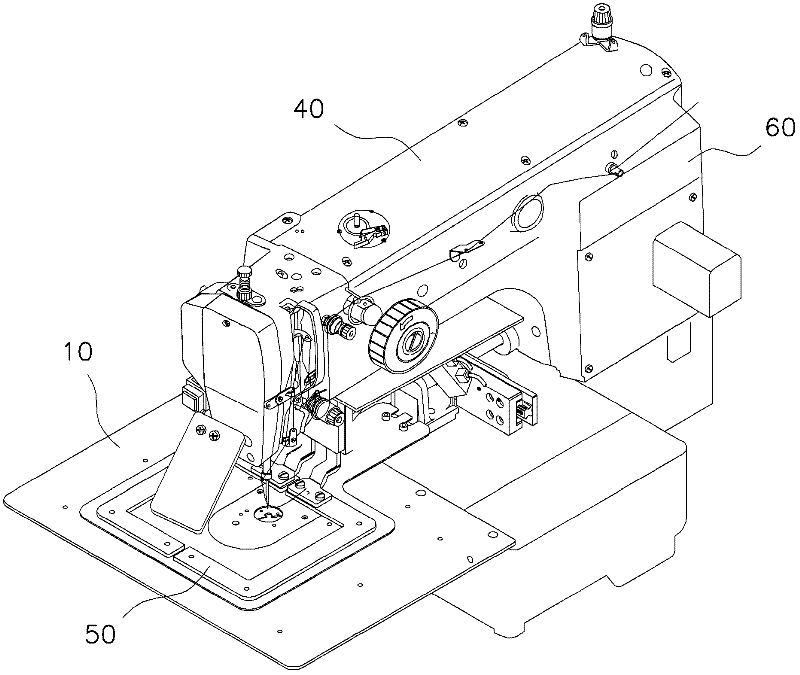

[0093] image 3 It is an overall perspective view of the first embodiment of the head unit movable bridge sewing machine of the present invention, Figure 4A It is the overall front view of the head unit movable bridge type sewing machine of the present invention, Figure 4B It is an overall perspective view of the X-axis transfer structure of the head unit and the bed unit of the head unit movable bridge sewing machine according to the present invention.

[0094] The sewing machine of the present invention is provided with a table top 510 for accommodating sewing objects at the top, support columns 502 positioned on both sides of the above-mentioned table top 510, an upper frame 520 and a lower frame 521 connected to the above-mentioned support columns 502 and located at the upper end and the lower e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com