Auxiliary turning device for turning-throwing machine

The technology of a turner and a throwing machine is applied to the preparation and application of organic fertilizers and organic fertilizers. It can solve the problems of increasing production costs, affecting material fermentation, and being unable to be operated, so as to achieve low cost, improve operating areas, Easy to replace and simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

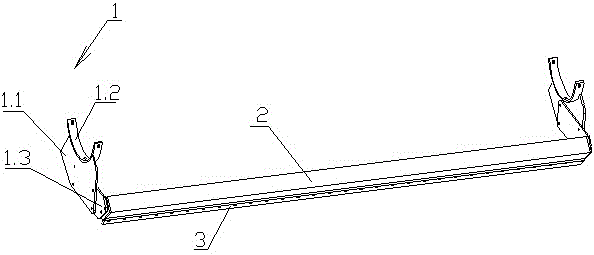

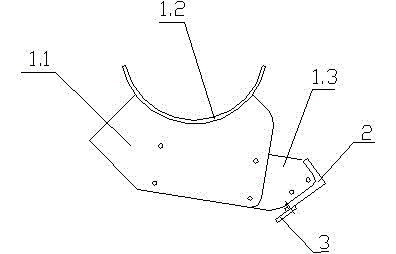

[0015] see figure 1 and figure 2 , the present invention relates to an auxiliary material turning device used on a turning and throwing machine, the auxiliary material turning device includes a connecting piece 1 arranged left and right, and the connecting piece 1 includes a connecting plate 1.1, and the connecting plate 1.1 The upper part is equipped with an arc-shaped installation plate 1.2, and the arc-shaped installation plate 1.2 is used to connect with the turning drum of the turning and polishing machine. 1.3 is connected with a turning board 2, the turning board 2 is arranged in an "L" shape, and a fragile strip 3 is arranged on the downward side of the "L" shaped turning board 2, and the fragile strip 3 The material is plexiglass or plastic; the purpose of setting the fragile strip 3 is that the fragile strip 3 will break if it encounters a stone or a steep ground in the process of sticking to the ground, so as not to affect the The normal operation of the turning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com