Needle rod for two-needle sewing machine, and switching mechanism for needle rod

A switching mechanism and sewing machine technology, applied in the direction of sewing machine needle holders, sewing machine components, sewing equipment, etc., can solve the problems of difficult processing and manufacturing, inability to switch positions, incomplete application, etc., and achieve simple and reliable switching actions, and convenient processing and assembly , control simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

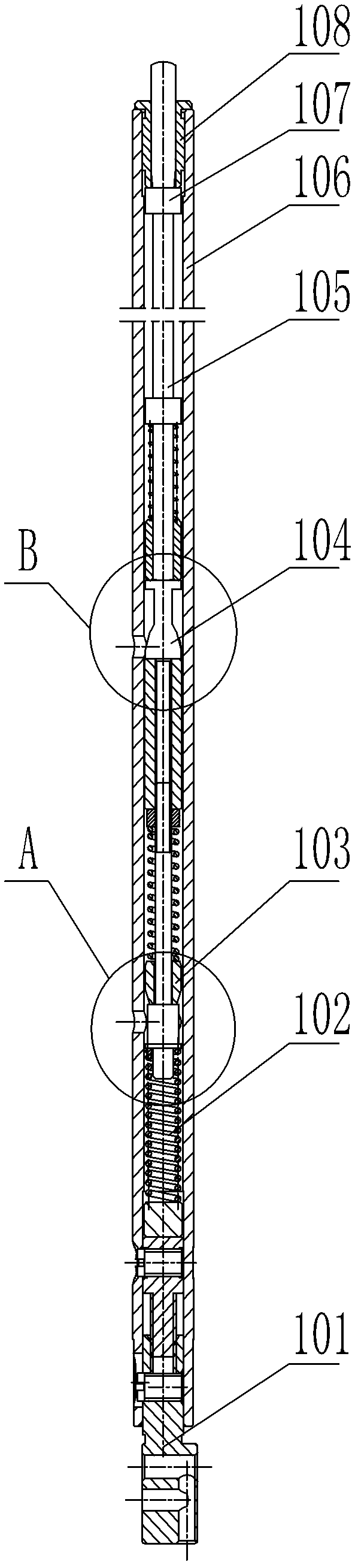

[0023] Such as figure 1 As shown, the needle bar of a double-needle sewing machine of the present invention includes a hollow needle bar body 106, and the lower end of the needle bar body 106 is fixedly connected with a needle bar head 101 for installing machine needles. In the needle bar body 106, a return spring 102, a first wedge 103, a second wedge 104, and a switch bar 105 are sequentially installed, and the upper end of the switch bar 105 is exposed from the needle bar body 106. The needle bar body 106 comes out, and in this embodiment, an end cover 108 is fixed on the upper end of the needle bar body 106, and the upper end of the switching pressure rod 105 passes through the end cover 108, and the switching pressure bar 105 is provided with a limiter that matches the end cover 108. Boss 107.

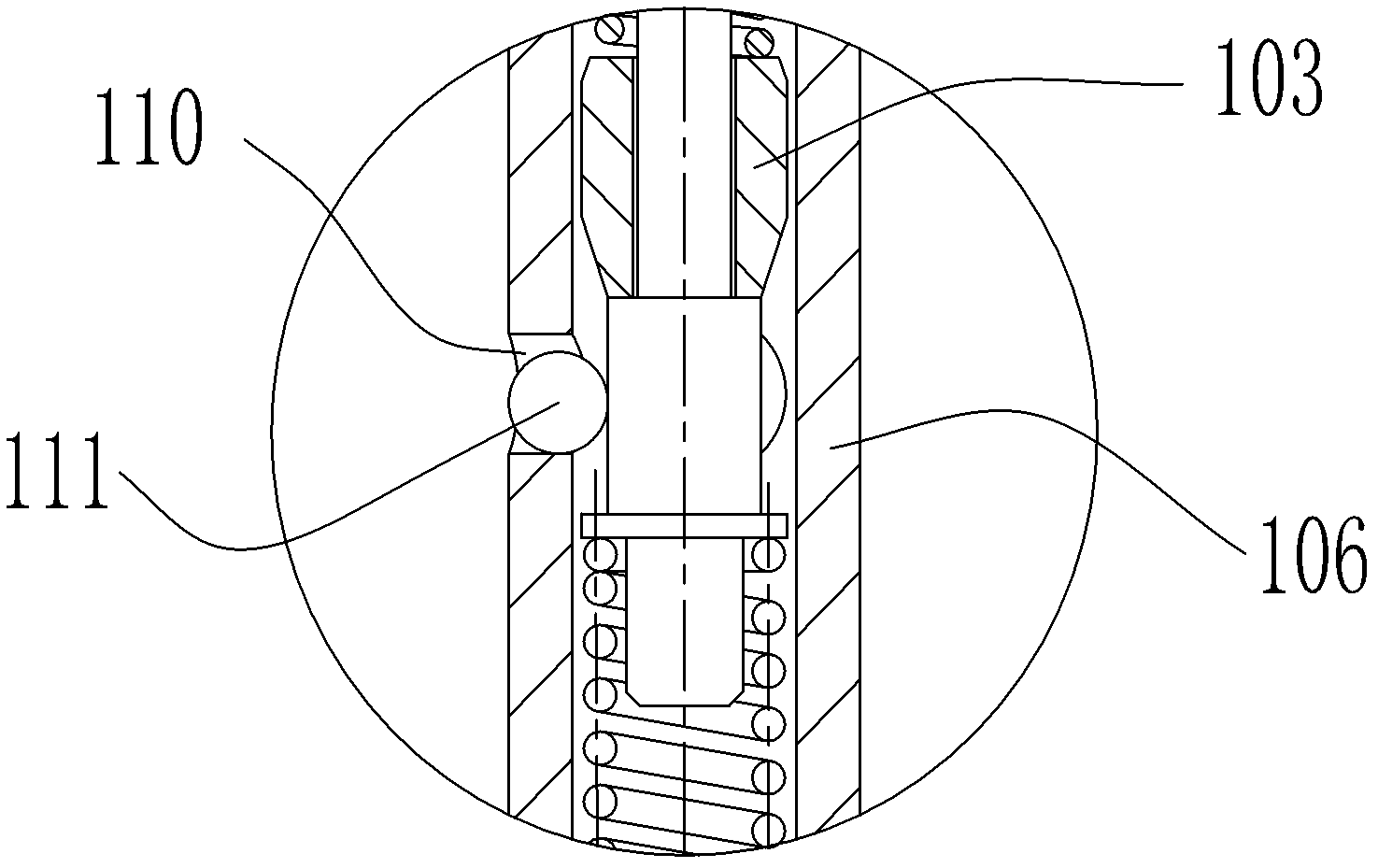

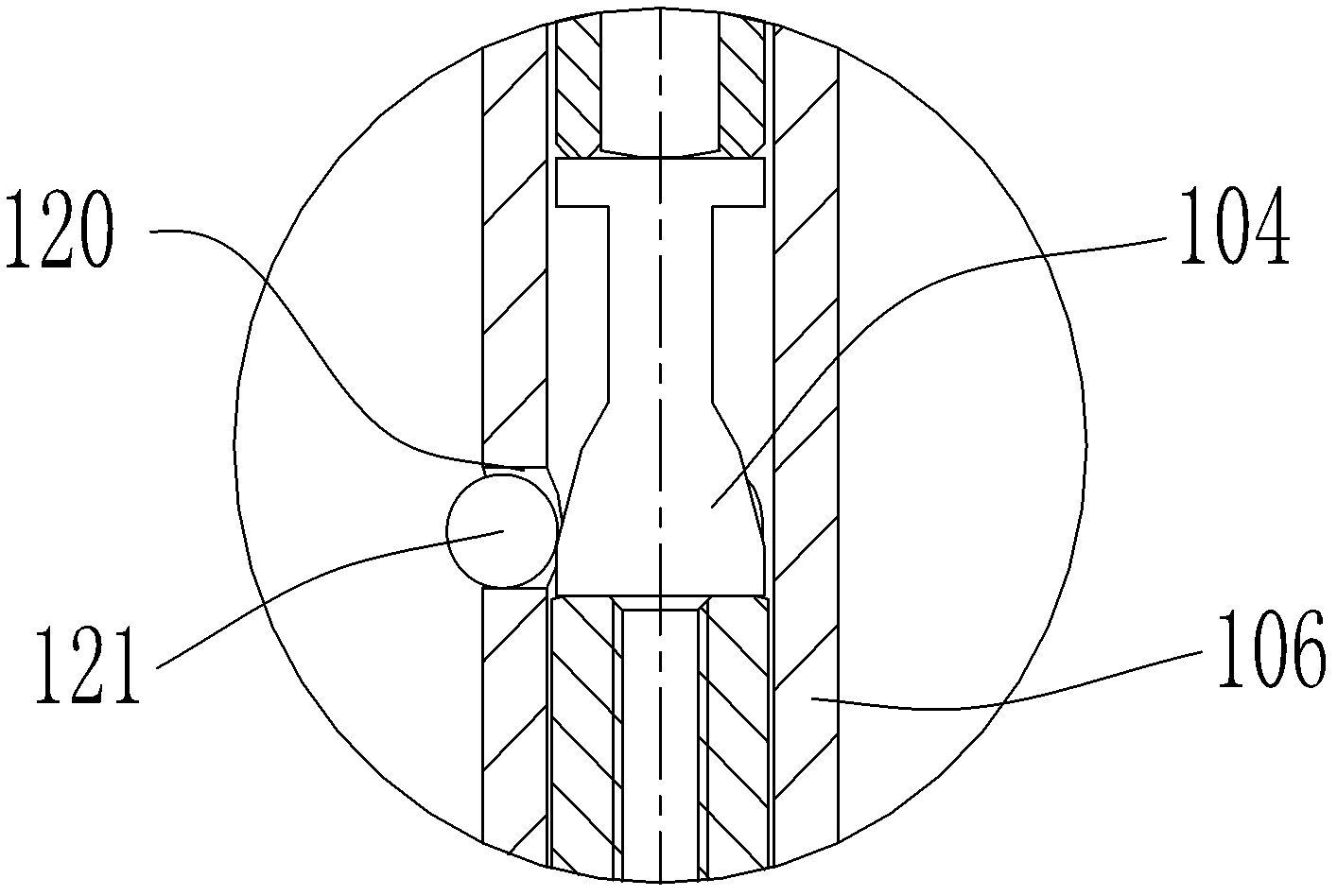

[0024] Such as figure 2 As shown, a first through hole 110 is opened on the side wall of the needle shaft body 106 at a position corresponding to the first wedge 103 , and a fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com